Flexible Packaging – A Step Ahead in the Evaluation and Development of Versatile Packaging

flexible packaging industry Introduction

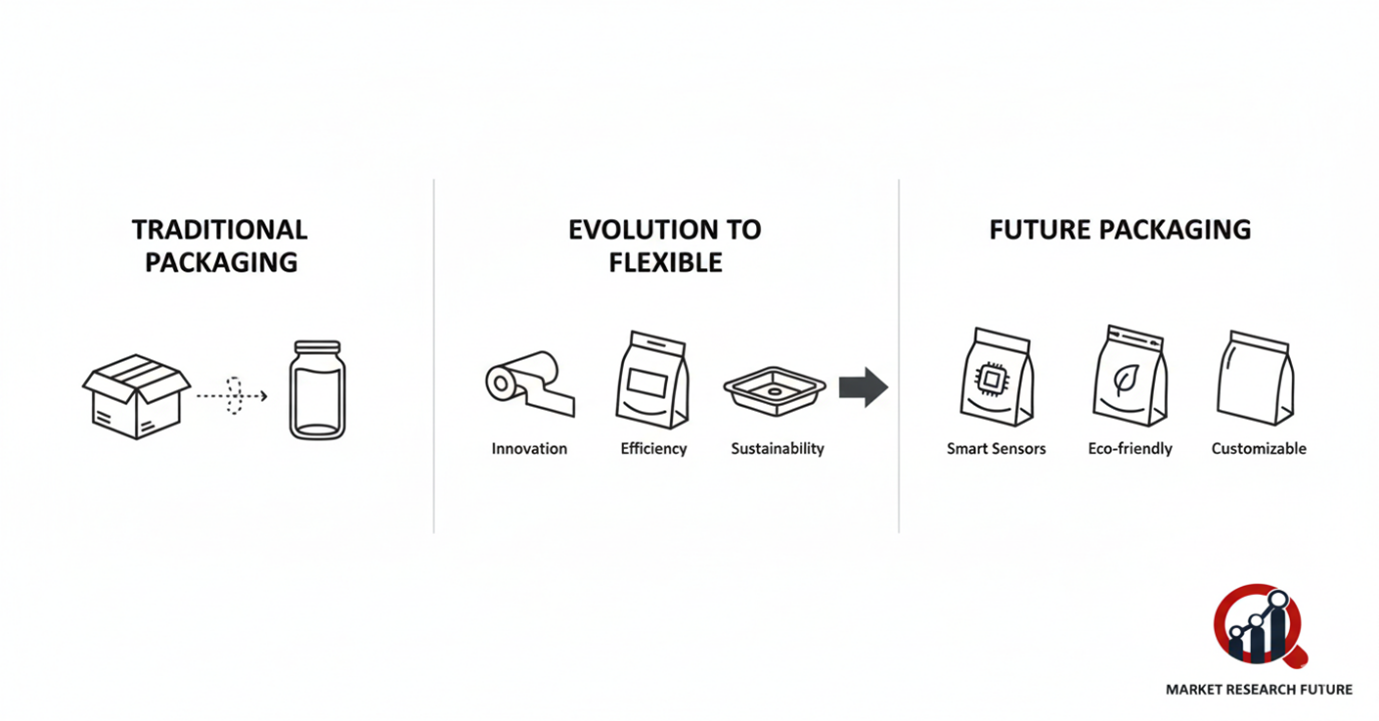

The flexible packaging industry is a rapidly expanding segment within the global packaging industry. Due to their lightweight and versatile characteristics, flexible packages can be made with cellophane, plastics, and foils and can be formed, filled, and sealed to accommodate a variety of products. Flexible packaging is used to make pouches, bags, wrapped products, and laminated films. Flexible packaging is durable, cost-efficient, and convenient, making it a packaging option tailored to modern consumer and manufacturer needs.

Changing Customer Preferences Driving Growth

As customers’ lifestyles and purchasing patterns shift, so do their expectations. Flexible packaging is designed for those who want convenience and simplicity. Products that can be effortlessly opened, stored, and carried are packaged in flexible packaging. Today, people lead increasingly busy lives, and those living in smaller households are looking for packaging that is easy to handle and disposable.

Flexible packaging is used in a wide variety of industries beyond food and drink, including pharmaceuticals, personal care, and health products. Consumer behavior is largely influenced by packaging. Integrating innovative and eye-catching flexible packaging is often the key factor motivating customers to complete a purchase.

Modern flexible packaging solutions such as bake-in-the-carton, mix-in-the-pouch, and serve-from-the-tray formats showcase a strong consumer focus. Innovations such as these are increasingly popular due to a consumer trend towards on-the-go and ready-to-use products, which help simplify day-to-day activities.

The Leading Use of Plastic in Flexible Packaging

Plastic is, and most likely will continue to be, the dominant material in flexible packaging. It is used in numerous industries, including food and beverages, pharmaceuticals, cosmetics, tobacco, and personal care. Common plastic materials such as polypropylene (PP), polyethylene terephthalate (PET), PVC, and polystyrene (PS) are flexible, strong, lightweight, recyclable, and generally durable.

The introduction of biopolymers and other eco-friendly materials as plastic alternatives is a growing trend in the industry. Unsustainable consumption is a concern among consumers, and brands are addressing this. The new sustainable alternatives or biodegradable polymers help reduce waste and carbon footprints while still maintaining the practical benefits of traditional plastics.

The Growing Use of Flexible Packaging

Flexible packaging contributes to the safe, efficient, and cost-effective transportation of products, which is a significant requirement in certain industries. In the pharmaceutical and food industries, flexible packaging aids in the safe handling of products, making distribution easier. Also, flexible packaging helps prolong the shelf life of the product.

In developing countries, people need more packaged food and food products, more nutritional products, and more products for hygiene. The development of organized retail and e-commerce is increasing the more advanced packaging formats. Added to that, the new fully automated packaging and distribution centers need advanced packaging technologies that provide greater barrier protection and integrity of the wrapped products, which continue to grow and expand the packaging market.

Regional Growth Dynamics

The Asia-Pacific Region, especially China and India, is a major flexible packaging industry. The flexible packaging growth is driven by the large population, rising disposable income, packaged food consumption, and rapid urbanization.

Top industry players, Huhtamaki Group, Amcor Limited, Mondi Group, Hindalco, and Uflex Limited, are expanding their investments in the Asia-Pacific to optimize or get the most out of growing returns. The region’s e-commerce and retail growth, along with government investments in changing the packaging for eco-friendly products, are likely to provide further support for this growth in changing flexible packaging for the next few years.

Future Outlook: Technology and Innovation

The packaging industry changers are integrating more nanotechnology. Flexible packaging is becoming stronger, more shelf stable, and barrier more becoming greater, making the flexible packaging usable for wrap products like pharmaceuticals and cosmetics.

Anticipating the future for the global flexible packing market, we envision unceasing innovation, positive, innovative, and sustainable constructive growth with the rise in adoption in many sectors. An increase in the use of flexible packing to enhance waste reduction, product protection, and better brand enhancement is sweeping the globe.

Conclusion

At the turning point gets the embrace of cutting-edge. On the cross point of the innovative, the functional, and the sustainable, the garment with the clever, flexible packing gets, and gets, gets the call for the present with the get the present with the get the innovative. With the embrace of the new cutting edge in innovative packing with flexible innovative cutting-edge packing gets leaves gets the, gets the call. The cutting-edge, flexible, innovative packing gets the call the center of packing for the globe with the packing. The present for innovative gets with flexible gets to the new end for offering the best in flexible, innovative the cutting-edge.

Leave a Comment