Condition Monitoring and NDT Services Market Overview

The global condition monitoring and NDT services market is experiencing steady growth, driven by the increasing need for asset management, maintenance, and risk mitigation across various industries, including manufacturing, oil & gas, aerospace, and construction. These services are integral in ensuring the reliability, safety, and longevity of equipment and infrastructure by detecting defects and anomalies without compromising their integrity. As industries push toward greater operational efficiency and safety, the demand for condition monitoring and NDT services is expanding, with businesses turning to innovative technologies and procurement strategies to stay ahead of the curve.

Our report provides a detailed analysis of emerging trends in the condition monitoring and NDT services market, focusing on opportunities for cost-effective sourcing and the integration of advanced technologies like IoT-based monitoring systems and automated NDT techniques. We also highlight challenges in supply chain management and emphasize the importance of leveraging digital procurement tools to forecast market trends and manage risks effectively.

The outlook for the condition monitoring and NDT services market is robust, with several key trends and projections indicating growth through 2032:

- Market Size: The global condition monitoring and NDT services market is expected to reach approximately USD 13.8 billion by 2032, reflecting a compound annual growth rate (CAGR) of about 6.8% from 2024 to 2032.

Key Sector Contributions:

- Manufacturing and Industrial Equipment: Increased adoption of predictive maintenance and condition monitoring systems is boosting demand for NDT services in manufacturing.

- Oil & Gas: The need for infrastructure inspection and maintenance, especially in offshore oil platforms, is driving the demand for condition monitoring and NDT services.

- Aerospace and Aviation: Condition monitoring and NDT are critical in ensuring aircraft safety and compliance with regulatory standards.

- Construction and Infrastructure: Growing demand for the assessment of structural integrity and safety in construction projects is pushing demand for these services.

Technological Transformation and Innovations:

- IoT Integration: The integration of IoT-based condition monitoring systems is transforming the market by providing real-time data on asset health, enabling predictive maintenance and reducing downtime.

- Automated NDT: The use of robotics and drones for NDT, particularly in hard-to-reach areas, is expanding the scope and efficiency of these services.

- Artificial Intelligence: AI-driven analysis of inspection data is improving defect detection accuracy and operational decision-making, further enhancing the value proposition of condition monitoring and NDT services.

Funding Initiatives:

- Research and Development: Increased funding in the development of advanced NDT technologies, such as ultrasonic testing and X-ray systems, is expected to enhance the quality and reliability of these services.

- Sustainable Practices: Investment in sustainable condition monitoring practices, such as non-invasive testing, is expected to grow as industries aim to reduce environmental impact while maintaining operational safety.

Regional Insights:

- North America: Dominates the condition monitoring and NDT services market, driven by high adoption rates in the oil & gas, aerospace, and manufacturing sectors.

- Europe: Significant growth in aerospace and automotive sectors, coupled with strict safety regulations, is fuelling demand.

- Asia-Pacific: Rapid industrialization and infrastructure development in emerging economies, particularly in China and India, are creating new opportunities for condition monitoring and NDT services.

Key Trends and Sustainability Outlook:

- Sustainability Initiatives: The trend toward sustainability is driving the adoption of non-invasive, eco-friendly NDT methods. Additionally, the emphasis on asset longevity through condition monitoring is contributing to the reduction of waste and resource consumption.

- Health and Safety Regulations: Increasing regulatory pressure around safety standards in various industries is pushing companies to adopt condition monitoring and NDT services to avoid costly accidents and downtime.

Growth Drivers:

- Regulatory Compliance: Stricter safety and environmental regulations across industries are driving the demand for NDT and condition monitoring services.

- Global Infrastructure Development: Expanding infrastructure projects worldwide are requiring robust condition monitoring and NDT services to ensure safety and operational continuity.

- Digital Transformation: The rise of digital technologies and data analytics is revolutionizing condition monitoring and NDT services, enhancing both the efficiency and effectiveness of inspections.

Overview of Market Intelligence Services for the Condition Monitoring and NDT Services Market

Recent analysis indicates that the condition monitoring and NDT services market faces fluctuating pricing and demand due to industry-specific factors like safety standards and technological advancements. To navigate these challenges, market reports provide cost forecasts, supplier evaluations, and procurement strategies, helping stakeholders optimize their purchasing decisions. By leveraging insights from these reports, businesses can better manage cost fluctuations, access high-quality services, and identify strategic sourcing opportunities. Implementing advanced digital procurement tools can enable stakeholders to mitigate risks, enhance supply chain efficiency, and strengthen their competitive advantage in the marketplace.

Procurement Intelligence for Condition Monitoring and NDT Services Market: Category Management and Strategic Sourcing

"To stay ahead in the condition monitoring and NDT (Non-Destructive Testing) services market, companies are refining their procurement strategies by utilizing spend analysis solutions for vendor spend assessments and optimizing supply chain operations through in-depth supply market intelligence. Category management and strategic sourcing are crucial in achieving cost-effective procurement, ensuring the availability of high-quality testing services, and enhancing operational efficiency. With the integration of innovative technologies such as IoT-based condition monitoring systems and automated NDT solutions, companies are improving their procurement processes to ensure timely and efficient service delivery, while managing risks and reducing costs."

Pricing Outlook for Condition Monitoring and NDT Services Market: Spend Analysis

The condition monitoring and non-destructive testing (NDT) services market is currently experiencing dynamic pricing trends influenced by technological advancements, regulatory requirements, and an increasing demand for proactive maintenance solutions. The market is navigating a landscape marked by evolving customer needs and the rising adoption of predictive maintenance technologies.

The line chart illustrating the pricing outlook for the Condition Monitoring and NDT Services market from 2024 to 2032.

Our advanced analysis indicates a steady upward trajectory in NDT service prices driven by several key factors, including:

- Technological Advancements: The integration of IoT, AI, and cloud-based solutions in condition monitoring and NDT services is increasing operational efficiency and demand for specialized equipment, contributing to price increases.

- Rising Demand for Preventive Maintenance: Industries such as aerospace, oil and gas, and manufacturing are increasingly adopting predictive maintenance, driving the demand for condition monitoring and NDT services.

- Regulatory Compliance: Stricter regulations around safety and quality standards in sectors like energy, transportation, and manufacturing are contributing to higher service costs.

- Labor Costs: The need for skilled professionals and advanced training in NDT services is increasing operational costs, which impacts pricing.

- Supply Chain Constraints: Delays and higher costs in obtaining specialized equipment and materials required for NDT services are creating upward pricing pressure.

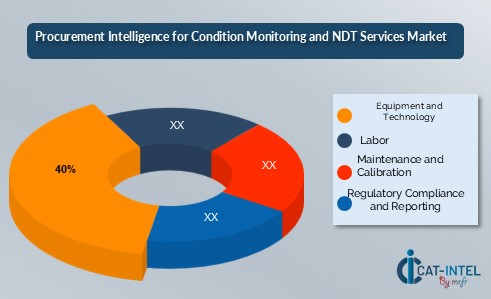

Cost Breakdown for the Condition Monitoring and NDT Services Market: Cost saving opportunities

- Equipment and Technology (40%)

- Description: This segment encompasses the costs associated with advanced diagnostic tools, sensors, and software platforms essential for effective condition monitoring and NDT services.

- Trends: The market is witnessing a shift towards integrating Internet of Things (IoT) devices, drones, and robotics to enhance inspection capabilities. These technologies enable real-time data collection and analysis, improving efficiency and accuracy.

- Cost-Saving Opportunities:

- Adoption of Remote Monitoring: Implementing remote monitoring solutions can reduce the need for on-site inspections, thereby lowering labour and travel expenses.

- Investment in Automation: Utilizing automated inspection systems can decrease manual labour costs and minimize human error, leading to more reliable results.

- Labor (XX%)

- Maintenance and Calibration (XX%)

- Regulatory Compliance and Reporting (XX%)

Cost saving opportunity: Negotiation Lever and Purchasing Negotiation Strategies

In the Condition Monitoring and NDT services market, cost-saving opportunities can be achieved through collaborative purchasing, bulk discounts, and leveraging remote monitoring and automation to reduce labour costs. Integrating advanced technologies like drones and IoT can optimize inspections, improve efficiency, and lower operational expenses. Adopting precision maintenance and energy-efficient solutions extends equipment lifespan and reduces utility costs. Vendor consolidation and long-term contracts ensure better pricing and predictable costs, while transportation optimization helps minimize logistics expenses. These strategies collectively enhance procurement efficiency and reduce overall operational costs.

Supply and Demand Overview of the Condition Monitoring and NDT Services Market: Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The Condition Monitoring and NDT (Non-Destructive Testing) services market is experiencing growth due to increasing industrialization, rising safety and compliance regulations, and the need for efficient asset management and predictive maintenance solutions.

Demand Factors:

- Industrial Growth: Rising industrial activities across sectors such as oil and gas, manufacturing, aerospace, and energy drive demand for condition monitoring and NDT services to ensure operational safety and efficiency.

- Safety and Compliance Regulations: Stringent regulatory requirements for equipment safety, environmental compliance, and risk management further boost demand for NDT services to prevent catastrophic failures.

- Predictive Maintenance: Growing emphasis on predictive maintenance strategies, as companies seek to reduce downtime and maintenance costs, driving demand for advanced condition monitoring solutions.

- Technological Advancements: Integration of IoT, AI, and machine learning in condition monitoring solutions enhances real-time data acquisition and analysis, leading to higher adoption rates across industries.

Supply Factors:

- Technological Innovation: Advancements in sensor technology, remote monitoring tools, and data analytics improve service offerings and increase supply capabilities for NDT providers.

- Skilled Labor Shortage: A shortage of trained NDT professionals can limit the availability of services, influencing supply and driving prices higher.

- Global Service Providers: Leading service providers with global reach ensure consistency in supply, especially in industries with international operations, but increased competition impacts pricing and service availability.

- Cost of Equipment: The high cost of NDT equipment and technology can influence the cost structure for service providers and, in turn, the supply of services in various markets.

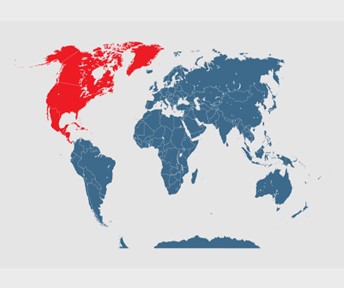

Regional Demand-Supply Outlook: Condition Monitoring and NDT Services Market

The image illustrates the growing demand for Condition Monitoring and NDT services, particularly in North America and Europe, with potential for increased competition and pricing pressures.

North America: A Key Player in the Condition Monitoring and NDT Services Market North America, particularly the U.S. and Canada, plays a pivotal role in the Condition Monitoring and NDT services market, characterized by:

- Leading Service Providers: North American companies dominate the global market for condition monitoring and NDT services, with advanced technologies and a wide range of solutions for industrial sectors such as oil & gas, aerospace, and manufacturing.

- Robust Demand: The industrialization and growth of key sectors, including oil & gas, automotive, and energy, drive significant demand for NDT and condition monitoring services to ensure safety, efficiency, and regulatory compliance.

- Technological Advancements: North America is at the forefront of technological innovation in condition monitoring, with advancements in AI, IoT, and machine learning providing predictive maintenance capabilities and enhancing service offerings.

- Regulatory Compliance: Stringent safety and compliance regulations in industries such as aerospace and energy drive the need for NDT services, especially in high-risk applications like nuclear power, transportation, and infrastructure.

- Skilled Workforce: A highly skilled workforce in NDT and condition monitoring technologies provides a competitive edge, although there is growing concern over a shortage of trained professionals to meet the increasing service demand.

- Export Opportunities: The region also exports NDT services to other industrialized regions, especially Europe and parts of Asia, increasing its global influence in the market.

North America remains a key hub for Condition Monitoring and NDT Services Market and its growth

Supplier Landscape: Supplier Negotiations and Strategies for Condition Monitoring and NDT Services Market

The Condition Monitoring and NDT services market has a diverse and competitive supplier landscape, comprising both global and regional players that provide critical technologies and services essential for maintaining equipment health, ensuring safety, and optimizing performance across industries such as aerospace, automotive, energy, and manufacturing. Key suppliers offer various solutions such as ultrasonic testing, infrared thermography, vibration analysis, and other inspection technologies that enhance operational efficiency and ensure compliance with safety standards.

Currently, the supplier landscape is characterized by close partnerships between NDT service providers and industrial clients, where collaboration is crucial for maintaining equipment reliability, enhancing performance, and reducing downtime. Additionally, suppliers offering advanced technologies in automation, AI, and machine learning are shaping the future of predictive maintenance and condition monitoring services.

Some of the key suppliers in the Condition Monitoring and NDT services market include:

- General Electric (GE)

- Siemens AG

- Emerson Electric Co.

- MISTRAS Group

- SKF Group

- Honeywell International Inc.

- Intertek Group

- RSL (RPS) NDT Solutions

- Ashtead Technology

- X-Rite, Inc.

Key Development: Procurement Category significant development

|

Procurement Category |

Key Development |

Impact |

|

Technology and Equipment |

Introduction of AI-powered predictive maintenance tools and automation systems |

Enhances the accuracy and efficiency of condition monitoring, reducing downtime and maintenance costs |

|

Supplier Relationships |

Stronger partnerships between NDT service providers and industries for tailored solutions |

Ensures higher quality of service, enhances customization, and optimizes long-term operational support |

|

Data and Analytics |

Growing adoption of cloud-based platforms for data storage and analysis |

Facilitates real-time monitoring and better decision-making through accessible and actionable insights |

|

Sustainability and Compliance |

Implementation of green technologies and sustainable practices in equipment usage |

Reduces environmental impact, supports regulatory compliance, and improves corporate sustainability practices |

|

Procurement Attribute/Metric |

Details |

|

Market Sizing |

The global condition monitoring and NDT services market is projected to grow from USD 2.87 billion in 2023 to USD 13.8 billion by 2032, with a CAGR of 6.8% during the forecast period. |

|

Adoption of Condition Monitoring |

Increasing adoption of predictive maintenance techniques and AI-powered solutions in industries such as manufacturing, oil & gas, and aerospace. |

|

Top Strategies for 2024 |

Focus on enhancing service offerings through digitalization, expanding into emerging markets, and integrating AI and IoT for real-time monitoring. |

|

Automation in NDT Services |

Over 35% of NDT services providers are incorporating automated inspection systems such as drones, robots, and remote sensors for efficiency and safety. |

|

Procurement Challenges |

Key challenges include high initial setup costs for advanced monitoring systems, maintaining service consistency, and addressing labor shortages in skilled NDT technicians. |

|

Key Suppliers |

Major players include SGS SA, Bureau Veritas, Intertek Group, TUV Rheinland, and Mistras Group, focusing on non-destructive testing solutions and condition monitoring technologies. |

|

Key Regions Covered |

Key markets include North America, Europe, and Asia-Pacific, with significant demand from the U.S., Germany, China, and India. |

|

Market Drivers and Trends |

Growth driven by the need for predictive maintenance, stringent safety regulations across industries, increasing industrial automation, and the expanding use of AI and IoT technologies. |

Frequently Asked Questions (FAQ):

Our procurement intelligence services offer a comprehensive analysis of the global supplier landscape for condition monitoring and NDT services. We provide spend analysis, supplier performance evaluations, and market intelligence to help you source services efficiently and cost-effectively, ensuring access to the best suppliers and pricing.

We assist in evaluating the Total Cost of Ownership (TCO) for sourcing these services by factoring in procurement costs, transportation, storage, and implementation expenses. Our cost analysis services help ensure you understand the long-term financial impact of condition monitoring and NDT services procurement.

We offer a detailed risk management framework that highlights potential supply chain disruptions, technological obsolescence, and compliance risks. Our solutions help mitigate risks associated with sourcing these services, ensuring consistent quality and reliable monitoring.

Our Supplier Relationship Management (SRM) services guide you in building strong partnerships with condition monitoring and NDT service providers. We focus on improving collaboration, negotiating favourable terms, and ensuring high service quality while maintaining cost efficiency.

We provide a thorough breakdown of procurement best practices for condition monitoring and NDT services, including sourcing models, supplier categorization, pricing strategies, and contract management. These practices help ensure informed, strategic procurement decisions.

Digital transformation is key to streamlining procurement in this market. We offer solutions that incorporate automation, IoT, and data analytics, enabling you to track supplier performance, monitor market trends, and optimize procurement strategies in real time.

Our supplier performance management solutions help you assess and monitor NDT service providers, ensuring they meet quality, delivery, and compliance standards. This supports better decision-making, reduces procurement risks, and enhances supplier relationships.

We provide insights into negotiation strategies, offering support in supplier negotiations to secure favourable pricing, service-level agreements, and contract terms. Our data-driven approach ensures your negotiations are backed by market intelligence.

We offer advanced market analysis tools that provide insights into global trends, supplier market share, and price forecasts. This data helps in understanding market conditions, identifying opportunities, and making more informed purchasing decisions.

Our procurement solutions include guidance on regulatory compliance in the NDT services market. We help you navigate complex procurement processes, ensuring that all suppliers adhere to industry standards, including safety, environmental, and quality regulations.

We offer strategies to mitigate supply chain disruptions by identifying backup suppliers, establishing contingency plans, and monitoring market trends. Our insights help ensure a stable and continuous flow of condition monitoring and NDT services despite potential challenges.

Through our supplier performance tracking tools, we help you monitor service quality, delivery timelines, and compliance. Regular supplier evaluations and performance reports provide transparency and help you optimize future procurement decisions.

We assist in identifying service providers who implement sustainable practices in NDT and condition monitoring. Our services include sustainability assessments, ensuring that the suppliers you choose meet your environmental, ethical, and social responsibility standards.

Our pricing analysis services allow you to compare costs across different service providers, ensuring you achieve competitive pricing. We analyze pricing trends, market dynamics, and negotiation levers to secure the best value for your organization.

We provide an in-depth analysis of market opportunities and risks, highlighting emerging trends in condition monitoring, NDT technologies, and service offerings. Our insights help you stay ahead of the competition by identifying strategic procurement opportunities and addressing market risks in the industry.