Summary Overview

DC Motors Market Overview

The global DC motors market is experiencing growth due to technological advancements, increasing demand for electric vehicles (EVs), automation, and industrial applications. DC motors, known for their efficiency and reliability, are utilized in a wide range of industries, including automotive, consumer electronics, industrial machinery, and robotics. As demand for energy-efficient solutions rises, DC motors are becoming increasingly essential in various sectors. Our report provides a comprehensive analysis of the current trends, challenges, and opportunities in sourcing DC motors, highlighting areas for cost savings through strategic sourcing, innovation in motor design, and advances in manufacturing techniques. We also examine the importance of digital procurement tools to forecast market needs, enabling businesses to stay ahead of the evolving market dynamics. Strategic sourcing and procurement management are critical for optimizing supply chain operations, particularly as companies increasingly rely on DC motors for automation, precision engineering, and sustainable energy solutions.

The outlook for the DC motors market is positive, with projections indicating substantial growth through 2032:

-

Market Size: The global DC motors market is projected to reach approximately USD 18.5 billion by 2032, reflecting a compound annual growth rate (CAGR) of about 6.9% from 2024 to 2032.

-

Sector Contributions: The growth of the DC motors market is primarily driven by:

-

Electric Vehicles (EVs): The automotive industry’s transition to electric vehicles is a key driver, with DC motors being widely used in EVs for their reliability and efficiency. -

Industrial Automation: DC motors are essential in automated manufacturing, robotics, and machinery, supporting the growth of industries focused on automation and precision manufacturing. -

Consumer Electronics: DC motors are increasingly used in appliances such as fans, washing machines, and vacuum cleaners, enhancing their energy efficiency and performance.

-

Technological Transformation and Innovations: The evolution of DC motor design, along with advancements in permanent magnet motors, brushless DC motors (BLDC), and wireless control technologies, is fuelling innovation in the market. The use of Internet of Things (IoT) and artificial intelligence (AI) for predictive maintenance and monitoring is also contributing to increased demand for DC motors. -

Funding Initiatives: Investments in research and development (R&D) for more efficient and durable motor technologies, as well as government incentives for EVs, are supporting the growth of the DC motors market. -

Regional Insights: North America, Europe, and Asia-Pacific are key regions driving demand for DC motors, with Asia-Pacific expected to see rapid growth due to the increased adoption of electric vehicles and industrial automation technologies.

Key Trends and Sustainability Outlook

-

Sustainability Initiatives: Environmental concerns and the shift towards energy-efficient solutions are pushing the development of low-energy DC motors, contributing to lower carbon footprints in various applications, particularly in transportation and industry. -

Health and Efficiency Trends: As industries aim to reduce energy consumption, the demand for high-efficiency DC motors is rising, leading to product innovations focused on energy-saving features. -

E-commerce Growth: Online retail platforms are expanding access to DC motors, especially for smaller applications, making them more accessible to industries and consumers worldwide.

Growth Drivers:

-

Electric Vehicle (EV) Adoption: The global push for electric vehicles, coupled with stricter emissions regulations, is driving the demand for DC motors, especially in electric propulsion systems. -

Automation and Robotics: The rise of Industry 4.0 and the increased adoption of robotics in manufacturing are contributing to the growing demand for DC motors in industrial applications. -

Global Population Growth: The expanding global population and urbanization are increasing the demand for consumer electronics and electric-powered machinery, boosting DC motor consumption. -

Digital Transformation: The integration of digital technologies in motor management, such as IoT and AI, is enhancing efficiency and predictability in motor performance, which further drives market growth.

Overview of Market Intelligence Services for the DC Motors Market

Recent analysis indicates that the DC motors market is witnessing fluctuations in raw material prices, labour costs, and demand dynamics due to supply chain disruptions. Market reports provide crucial insights into cost forecasts, enabling stakeholders to make informed procurement decisions. By leveraging these insights, companies can manage price volatility, optimize their procurement strategies, and secure access to high-quality DC motors. Strategic sourcing and procurement management become vital for minimizing risk and ensuring the timely availability of DC motors to meet production deadlines.

Procurement Intelligence for DC Motors Market: Category Management and Strategic Sourcing

"To stay competitive in the DC motors market, companies are optimizing procurement strategies by leveraging spend analysis, supply market intelligence, and supplier performance management solutions. Procurement category management and strategic sourcing are critical in ensuring the procurement of high-quality DC motors at competitive prices, enabling businesses to meet their operational and production needs."

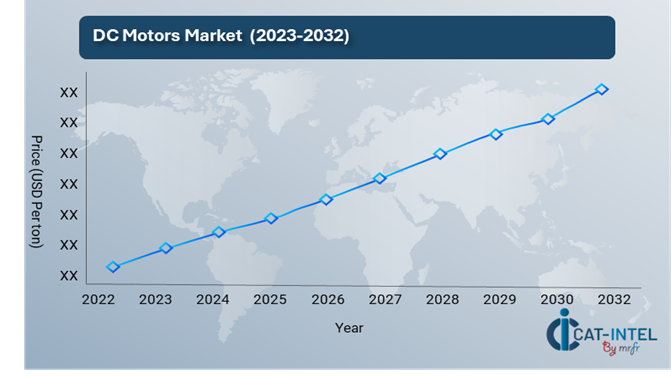

Pricing Outlook for DC Motors Market: Spend Analysis

The DC motors market is navigating a pricing environment influenced by several key factors, including technological advancements, raw material costs, and global demand fluctuations. As industries increasingly rely on automation, electric vehicles, and energy-efficient systems, pricing in the DC motors market is experiencing upward pressure.

Line chart illustrating the pricing outlook for the DC motors industry from 2024 to 2032: The chart would show the projected price trends, with prices steadily increasing over the years, influenced by several market dynamics.

Our advanced analysis indicates a steady increase in DC motor prices driven by the following key factors:

-

Rising Production Costs: The costs of raw materials such as copper, rare earth metals, and high-performance magnets are increasing, directly impacting the production cost of DC motors. -

Surge in Demand: The growing adoption of electric vehicles (EVs) and industrial automation is driving up demand for DC motors, which is contributing to higher pricing in both the automotive and manufacturing sectors. -

Export Opportunities: The demand for DC motors in international markets, particularly in Asia and Europe, is increasing, leading to competitive pressures on prices. This is also a factor in global price fluctuations. -

Technological Advancements: Continuous innovations in motor design, including improvements in efficiency, precision, and integration with digital technologies, are driving up costs. Newer models with enhanced features such as brushless DC motors (BLDC) and higher-efficiency variants are contributing to higher prices. -

Raw Material and Supply Chain Constraints: The availability of essential materials such as rare earth metals and the impact of supply chain disruptions are leading to price volatility. Additionally, labour shortages in manufacturing facilities are contributing to increased production costs.

Cost Breakdown for the DC Motors Market: Cost-Saving Opportunities

- Raw Materials (55%)

-

Description: This represents the cost of key raw materials used in the manufacturing of DC motors, such as copper, steel, and rare earth metals (e.g., neodymium and dysprosium), which are essential for motor windings and magnets. -

Trends: Prices of copper and rare earth metals have been volatile, influenced by global supply chain disruptions, mining challenges, and trade policies. As of 2024, copper prices are projected to increase due to growing demand from industries like electric vehicles (EVs) and renewable energy technologies, placing pressure on the overall cost of DC motors.

- Labor (XX%)

- Processing & Assembly (XX%)

- Infrastructure & Overheads (XX%)

Cost saving opportunity: Negotiation Lever and Purchasing Negotiation Strategies

In the DC motors market, cost-sav ing opportunities can be realized through strategies like bulk purchasing for volume discounts, supplier consolidation, and material substitution to reduce raw material costs. Energy-efficient production and process automation help lower operating expenses, while optimizing logistics and transportation cuts freight costs. Strategic partnerships and joint ventures can also drive down procurement costs by sharing resources and improving purchasing power. These tactics enhance efficiency and profitability for DC motor manufacturers.

Supply and Demand Overview of the DC Motors Market: Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The DC motors market is driven by growing demand across various industries, including automotive, industrial automation, and consumer electronics. Innovations in motor efficiency, miniaturization, and automation are fuelling market growth.

Demand Factors:

-

Industrial Automation: Increased automation in manufacturing and industrial sectors is driving demand for reliable and energy-efficient DC motors. -

Electric Vehicles (EVs): The rise of electric vehicles, which require efficient motors for power systems, is significantly boosting DC motor demand. -

Consumer Electronics: Growing applications in devices like home appliances, robotics, and power tools are expanding the market for DC motors. -

Energy Efficiency Focus: As industries prioritize energy-saving solutions, demand for high-efficiency motors continues to rise.

Supply Factors:

-

Technological Advancements: Innovations in motor design, such as brushless DC motors, are improving performance and efficiency. -

Global Manufacturing: Major production hubs, such as China and the United States, support the global supply of DC motors, ensuring availability. -

Raw Material Availability: The supply of key materials, like copper and rare earth metals, can impact motor production costs and availability. -

Market Competition: Intense competition among suppliers leads to price adjustments and quality improvements, influencing supply chain dynamics.

Regional Demand-Supply Outlook: DC Motors Market

The image shows growing demand for DC motors in North America and Asia, with potential price increases and heightened competition.

North America: A Key Player in the DC Motors Market North America, especially the United States, plays a crucial role in the DC motors market, characterized by:

-

Leading Producers: The U.S. is home to some of the world’s largest DC motor manufacturers, driving both innovation and production volume. -

Strong Industrial Demand: Key industries, including automotive, industrial automation, and robotics, are major consumers of DC motors, propelling demand. -

Focus on Electric Vehicles: With the rise of electric vehicle manufacturing in North America, demand for high-performance DC motors, particularly in EVs, is increasing significantly. -

Technological Advancements: The region leads in advancements such as brushless DC motors, improving efficiency and performance across various applications. -

Sustainability Initiatives: Efforts to reduce energy consumption and emissions are encouraging the use of energy-efficient motors, positioning North American manufacturers as leaders in green technology.

North America remains a key hub for DC Motors market and its growth

Supplier Landscape: Supplier Negotiations and Strategies – DC Motors Market

The DC motors market features a diverse and highly competitive supplier landscape, encompassing global and regional suppliers who provide critical components, raw materials, and advanced technologies for manufacturing DC motors. These suppliers play a pivotal role in ensuring the continuous production, innovation, and performance of DC motors used in a wide array of applications, from automotive and industrial sectors to consumer electronics and robotics.

Currently, the supplier landscape is characterized by strong collaborations between DC motor manufacturers and suppliers of key raw materials like copper, steel, and rare earth magnets, as well as essential components such as bearings, stators, and windings. Strategic supplier partnerships are critical for driving innovation in motor efficiency, enhancing production capabilities, and addressing the growing demand for energy-efficient and high-performance DC motors.

Some of the key suppliers in the DC motors market include:

- Nidec Corporation

- Siemens AG

- ABB Ltd.

- Bosch Group

- General Electric (GE)

- Mitsubishi Electric Corporation

- Maxon Motor AG

- Sanyo Denki Co., Ltd.

- Danfoss

- Baldor Electric Company (a member of the ABB Group)

Key Development: Procurement Category significant development

Procurement Category |

Significant Development |

Raw Materials |

Increased demand for high-quality copper and rare earth magnets due to rising adoption of electric motors and robotics. |

Energy Efficiency |

Development of more energy-efficient DC motors driven by global sustainability trends and regulatory requirements. |

Technology & Innovation |

Advancements in brushless DC motors (BLDC) and integration with IoT for smart motor applications in automotive & robotics. |

Supply Chain Management |

Enhanced digital procurement tools and data analytics to optimize inventory and reduce lead times. |

Sustainability Practices |

Adoption of eco-friendly manufacturing processes, including reduced carbon emissions in motor production. |

Supplier Collaboration |

Strengthened partnerships with raw material suppliers and component manufacturers to ensure high-quality and cost-effective production. |

Cost Management |

Increased focus on cost-effective sourcing of components, especially in global supply chains with fluctuating material prices. |

Customization |

Growth in demand for customized DC motors for specialized industries like robotics, automotive, and aerospace. |

Procurement Attribute/Metric |

Details |

Market Sizing |

The global DC motors market is expected to grow USD 18.5 billion by 2032, with a CAGR of 6.9% during the forecast period. |

Adoption of DC Motors |

Increasing adoption of DC motors in electric vehicles, robotics, and automation technologies drives demand. Brushless DC motors (BLDC) are gaining popularity for their energy efficiency and reliability. |

Top Strategies for 2024 |

Focus on energy-efficient motor designs, expanding product offerings (e.g., BLDC, permanent magnet motors), and advancing IoT integration for smarter operations. |

Automation in DC Motor Production |

Over 35% of motor manufacturing facilities are automating their processes, incorporating advanced robotics and AI-driven quality control systems to reduce costs and improve product quality. |

Procurement Challenges |

Key challenges include fluctuating raw material prices (e.g., copper), supply chain disruptions, and meeting stringent energy efficiency standards. |

Key Suppliers |

Leading suppliers include Siemens, Nidec Corporation, ABB, and Emerson Electric, focusing on energy-efficient and customizable motor solutions. |

Key Regions Covered |

Major markets include North America, Europe, and Asia-Pacific, with high demand in the automotive, robotics, and industrial sectors in the U.S., Germany, and China. |

Market Drivers and Trends |

Growth driven by increasing demand for electric vehicles, renewable energy applications, automation in industries, and advancements in motor efficiency and smart technologies. |