- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

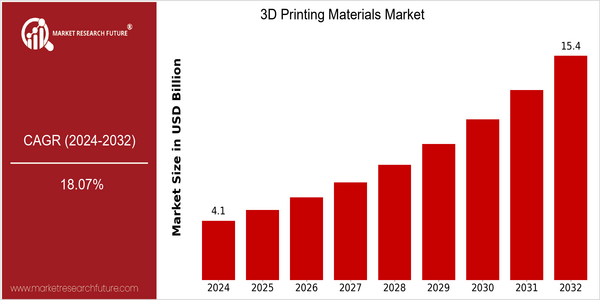

| Year | Value |

|---|---|

| 2024 | USD 4.1 Billion |

| 2032 | USD 15.4 Billion |

| CAGR (2024-2032) | 18.07 % |

Note – Market size depicts the revenue generated over the financial year

This is the third article in this series, and it is concerned with the 3D printing material market. The 3D printing material market is expected to grow from $4.1 billion in 2024 to $ 11.4 billion by 2032. This growth rate of 18.07% per year is quite impressive. The rapid development of the 3D printing material market is mainly driven by the rapid development of the 3D printing industry, which is driven by the rapid development of the 3D printing industry, which is mainly driven by the need for rapid prototyping and the need for customization. There are many other reasons for the rapid development of the 3D printing material market. The first is the development of materials and the second is the development of new printing technology. The development of high-performance materials such as advanced polymers and metal alloys has greatly expanded the application of 3D printing, and it is possible to manufacture complex and lightweight structures. The main players in the market, such as Stratasys, 3D System and Materialise, are investing heavily in research and development, establishing strategic cooperation with each other, and launching new products to enhance their competitiveness. Cooperation between material suppliers and 3D printer manufacturers has led to the development of a variety of materials that meet the needs of various industries, thus accelerating the development of the 3D printing material market.

Regional Market Size

Regional Deep Dive

The 3D Printing Materials Market is experiencing significant growth across the globe, owing to the technological advancements, increasing adoption of 3D printing in diverse industries, and the increasing emphasis on the need to adopt sustainable practices. Each region has its own distinctive characteristics, influenced by the economic conditions, regulations, and the attitude towards innovation. North America leads the way in terms of technological advancements and investment, Europe is focused on regulations and sustainability, while Asia-Pacific is expanding rapidly due to the growing demand for manufacturing. The Middle East and Africa are emerging as promising markets, and Latin America is beginning to adopt 3D printing across various industries.

Europe

- The European Union has implemented stringent regulations regarding the use of plastics, prompting companies to invest in sustainable 3D printing materials, such as bio-based and recycled materials, to comply with these regulations.

- Notable projects like the Horizon 2020 initiative are funding research and development in advanced 3D printing technologies, fostering collaboration between universities and industry leaders to drive innovation in the region.

Asia Pacific

- China is rapidly becoming a global leader in 3D printing materials, with significant investments from companies like Huawei and BYD, focusing on applications in automotive and electronics manufacturing.

- The region is witnessing a surge in startups specializing in innovative materials, such as metal and ceramic powders, driven by the increasing demand for customized manufacturing solutions in various industries.

Latin America

- Brazil is emerging as a key player in the 3D printing materials market, with local companies developing innovative solutions tailored to the agricultural sector, such as custom parts for machinery.

- Government programs aimed at fostering technology adoption in small and medium enterprises are encouraging the use of 3D printing, which is expected to drive demand for diverse materials in the region.

North America

- There are several companies in the United States, such as Stratasys and 3D Systems, which are at the forefront of the 3D printing industry, and are constantly expanding and developing their products in order to meet the needs of the aviation and medical industries.

- Recent regulatory changes in the U.S. have encouraged the use of biodegradable and eco-friendly materials in 3D printing, aligning with the growing trend towards sustainability and reducing environmental impact.

Middle East And Africa

- In the United Arab Emirate, where I was born, 3D printing is an important part of the national program to diversify the economy away from oil. The city of Dubai has a plan to have one quarter of its buildings 3D printed by the year 2030.

- The region is seeing collaborations between local universities and international companies to develop specialized materials for construction and healthcare applications, which are expected to enhance local manufacturing capabilities.

Did You Know?

“Did you know that 3D printing can reduce material waste by up to 90% compared to traditional manufacturing methods, making it a more sustainable option for production?” — National Institute of Standards and Technology (NIST)

Segmental Market Size

The 3D printing materials market plays a key role in the 3D printing market, which is experiencing a boom as a result of developments in materials science and the increasing demand for individualized solutions. The demand for lightweight construction in the aviation and automobile industries is a major driver of this market. In addition, rapid prototyping in production processes is gaining importance. Regulations that encourage the use of additive manufacturing in various industries are also increasing the demand for new materials. The development of 3D printing materials is currently in its maturity phase, with companies such as Stratasys and Materialise developing specialized materials for a wide variety of applications. A number of notable use cases demonstrate the versatility of this technology. Examples include the manufacture of complex aeronautical components and medical devices. Also driving the market are trends such as the growing importance of sustainability, which encourages companies to use eco-friendly materials to reduce their carbon footprint. In the future, developments such as bio-based polymers and metal powders will enable more sustainable and efficient manufacturing processes.

Future Outlook

From 2024 to 2032, the market for 3D printing materials will increase from $ 4.1 billion to $ 15.4 billion, with a robust CAGR of 18.07%. The accelerated growth of the market is due to the increasing use of additive manufacturing in various industries, including aeronautics, automobiles, health care and consumer goods. The high demand for advanced 3D printing materials, such as high-performance polymers, metals and composites, is expected to increase further as companies seek to optimize their production and reduce waste. The market penetration of 3D printing in the production process is expected to reach approximately 25 % in 2032, compared to 10 % in 2024. This is a significant trend towards more modern production methods. The development of biodegradable and recyclable materials will play a crucial role in shaping the market. The supportive government policies that promote sustainable manufacturing and R & D will also help to increase the growth of the market. Also, the emergence of on-demand manufacturing and the growing demand for custom-made products will increase the demand for 3D printing materials. The evolution of the 3D printing materials market will continue to grow as more industries adopt digital transformation. It will also offer investors significant opportunities and drive innovation in the field of materials.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 2.9 Billion |

| Market Size Value In 2023 | USD 3.4 Billion |

| Growth Rate | 20.45% (2023-2032) |

3D Printing Material Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.