- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

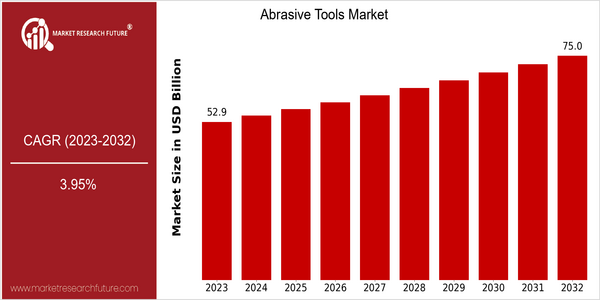

| Year | Value |

|---|---|

| 2023 | USD 52.89 Billion |

| 2032 | USD 75.0 Billion |

| CAGR (2024-2032) | 3.95 % |

Note – Market size depicts the revenue generated over the financial year

The world market for abrasives is valued at about 52.89 billion dollars in 2023, and is expected to reach 75 billion dollars in 2032, growing at a compound annual growth rate of 3.95% from 2024 to 2032. This growth trend is mainly driven by the increasing demand for abrasive tools in various industries. As the industry develops, the demand for high-quality materials and advanced manufacturing techniques will also drive the market. In addition, the automation of production lines and the development of emerging markets will also drive the market. Ceramic abrasives and superabrasives are developed, with better efficiency and performance, and have attracted more and more major players to invest. The abrasives industry is not yet mature, but companies such as 3M, Saint-Gobais, and Norton Abrasives have launched a series of strategic cooperation and new product development. This shows that the abrasives industry is developing rapidly and has great potential for development in the future.

Regional Market Size

Regional Deep Dive

The abrasive tools market is characterized by diverse dynamics across different regions, influenced by industrial growth, technological developments, and regulatory frameworks. In North America, the market is driven by the growth in the manufacturing sector and the rising demand for precision tools. Europe is characterized by a strong emphasis on innovation and sustainability, while Asia-Pacific is characterized by rapid industrialization and urbanization, which is resulting in a high demand for abrasive tools. Middle East and Africa is characterized by growth in the construction and manufacturing sectors, while Latin America is gradually establishing its market presence.

Europe

- In Europe, there is a notable trend towards the adoption of digital technologies in manufacturing processes, with companies like Bosch and Klingspor investing in smart abrasive solutions that enhance productivity and reduce waste.

- The European Union's stringent regulations on product safety and environmental standards are compelling manufacturers to innovate, leading to the development of safer and more sustainable abrasive tools.

Asia Pacific

- The Asia-Pacific region is experiencing rapid growth in the abrasive tools market, particularly in countries like China and India, where industrialization and urbanization are driving demand for construction and manufacturing tools.

- Key players such as Makita and Hitachi are expanding their operations in this region, focusing on local production to meet the increasing demand and reduce costs.

Latin America

- Latin America is gradually emerging as a key player in the abrasive tools market, with countries like Brazil and Mexico investing in manufacturing capabilities to support local industries.

- Government initiatives aimed at boosting the manufacturing sector, such as Brazil's 'Industry 4.0' program, are encouraging the adoption of advanced abrasive technologies and tools.

North America

- The North American market is seeing a surge in demand for advanced abrasive tools, particularly in the automotive and aerospace sectors, driven by companies like 3M and Norton Abrasives, which are focusing on product innovation and efficiency.

- Regulatory changes aimed at reducing environmental impact are pushing manufacturers to develop eco-friendly abrasive products, with organizations such as the Environmental Protection Agency (EPA) promoting sustainable practices in the industry.

Middle East And Africa

- In the Middle East and Africa, significant investments in infrastructure projects, such as the NEOM project in Saudi Arabia, are boosting the demand for abrasive tools, with local companies like Al-Futtaim Engineering leading the charge.

- The region's unique economic factors, including fluctuating oil prices, are influencing the market dynamics, prompting manufacturers to adapt their strategies to maintain competitiveness.

Did You Know?

“Did you know that the global abrasive tools market is expected to see a significant shift towards the use of diamond abrasives, which are known for their superior cutting efficiency and durability?” — Market Research Future

Segmental Market Size

The abrasive tool market is characterized by a steady growth pattern, which is primarily driven by the increasing demand for precision machining and surface finishing in various industries, such as automobile, aeronautics and construction. It is also favored by the growing need for a high-quality surface finish and the increasing use of advanced production techniques that require specialized abrasive tools. Also, the regulatory environment, which encourages the safety and productivity of manufacturing processes, has a positive effect on the demand for these tools. The current stage of development of the abrasive tool market is mature, with 3M and Norton leading in innovation and market share. North America and Europe are leading the way in the use of abrasive tools, implementing the most advanced production techniques. The main application areas are metalworking, woodworking and construction, where abrasive tools are needed for cutting, grinding and polishing. In terms of trends, the most important are the increasing trend towards automation and the introduction of sustainable production. Diamond abrasives and advanced ceramic materials are influencing the evolution of this market.

Future Outlook

The abrasive tools market is projected to grow at a CAGR of 4.36% between the years 2023 and 2032. The demand for precision machining and surface finishing is expected to rise across the various industries, such as automobile, aviation, and construction. The need for high-performance abrasive tools that can deliver better results is expected to drive the market penetration. The abrasives market is also expected to grow significantly in the emerging economies, as the pace of industrialization is accelerating. Technological developments, such as the development of advanced ceramic abrasives and the integration of artificial intelligence in the manufacturing processes, are expected to transform the abrasives market. Also, the growing focus on sustainable development and government regulations on reducing the negative impact on the environment is expected to drive the demand for eco-friendly abrasives. In the near future, automation and smart manufacturing are expected to boost the efficiency and effectiveness of abrasive tools. Hence, the abrasives market is expected to be an integral part of the manufacturing industry in the near future.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 8.9% (2023-2032) |

Abrasive Tools Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.