- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

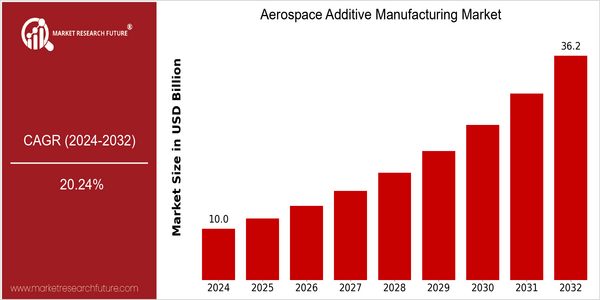

| Year | Value |

|---|---|

| 2024 | USD 9.967896 Billion |

| 2032 | USD 36.25 Billion |

| CAGR (2024-2032) | 20.24 % |

Note – Market size depicts the revenue generated over the financial year

The Aerospace Additive Manufacturing Market is poised for significant growth, with a current market size of approximately USD 9.97 billion in 2024, projected to expand to USD 36.25 billion by 2032. This remarkable growth trajectory reflects a compound annual growth rate (CAGR) of 20.24% over the forecast period. The increasing adoption of additive manufacturing technologies in aerospace applications is driven by the need for lightweight components, enhanced design flexibility, and reduced production lead times. As aerospace manufacturers seek to optimize their supply chains and improve operational efficiencies, the demand for advanced manufacturing techniques is expected to surge. Key technological trends, such as the development of high-performance materials and advancements in 3D printing technologies, are further propelling market growth. Companies like Boeing, Airbus, and GE Aviation are at the forefront of this transformation, investing in research and development to integrate additive manufacturing into their production processes. Strategic initiatives, including partnerships with technology firms and investments in innovative startups, are also shaping the competitive landscape. For instance, collaborations aimed at enhancing material properties and expanding the range of applications for additive manufacturing are likely to play a crucial role in driving the market forward.

Regional Market Size

Regional Deep Dive

The Aerospace Additive Manufacturing Market is experiencing significant growth across various regions, driven by advancements in technology, increasing demand for lightweight components, and the need for cost-effective manufacturing solutions. Each region exhibits unique characteristics influenced by local industry dynamics, regulatory frameworks, and technological capabilities. North America leads in innovation and investment, Europe focuses on sustainability and regulatory compliance, while Asia-Pacific is rapidly adopting additive manufacturing technologies to enhance production efficiency. The Middle East and Africa are emerging markets with potential for growth, and Latin America is gradually recognizing the benefits of additive manufacturing in aerospace applications.

Europe

- The European Union has launched initiatives to promote sustainable aviation, leading to increased investment in additive manufacturing technologies that reduce material waste and energy consumption.

- Companies like Airbus are collaborating with research institutions to develop new materials and processes for additive manufacturing, enhancing the capabilities and applications of 3D printing in aerospace.

Asia Pacific

- Countries like China and Japan are rapidly advancing in aerospace additive manufacturing, with government support for research and development initiatives aimed at boosting local manufacturing capabilities.

- Japanese companies such as Mitsubishi Heavy Industries are exploring the use of additive manufacturing for producing complex aerospace components, which is expected to enhance their competitive edge in the global market.

Latin America

- Brazil is emerging as a key player in the aerospace additive manufacturing market, with companies like Embraer exploring 3D printing for producing lightweight components.

- Government programs aimed at fostering innovation in manufacturing are encouraging local firms to adopt additive manufacturing technologies, which could enhance the region's aerospace capabilities.

North America

- The United States is home to major aerospace companies like Boeing and Lockheed Martin, which are heavily investing in additive manufacturing technologies to streamline production processes and reduce costs.

- Recent regulatory changes by the FAA have facilitated the certification of 3D-printed parts, encouraging more aerospace manufacturers to adopt additive manufacturing in their production lines.

Middle East And Africa

- The UAE is investing heavily in aerospace technology, with initiatives like the Dubai Aerospace Enterprise focusing on integrating additive manufacturing into their operations to improve efficiency.

- Local companies are beginning to collaborate with international firms to leverage additive manufacturing technologies, which is expected to drive innovation and growth in the region's aerospace sector.

Did You Know?

“Additive manufacturing can reduce the weight of aerospace components by up to 70%, significantly improving fuel efficiency and performance.” — Aerospace Manufacturing and Design

Segmental Market Size

The Aerospace Additive Manufacturing segment is experiencing robust growth, driven by the increasing demand for lightweight components and complex geometries that traditional manufacturing methods cannot achieve. Key factors propelling this demand include the need for cost-effective production processes and the push for sustainability in aerospace manufacturing, as companies seek to reduce waste and energy consumption. Regulatory policies promoting innovation in aerospace technologies further enhance this segment's appeal. Currently, the adoption stage of Aerospace Additive Manufacturing is transitioning from pilot phases to scaled deployment, with companies like Boeing and Airbus leading the charge. Notable projects include Boeing's use of 3D printing for producing parts for the 787 Dreamliner. Primary applications encompass the production of engine components, structural parts, and tooling, showcasing the technology's versatility. Trends such as the increasing focus on sustainability and government initiatives aimed at advancing aerospace technologies are catalyzing growth. Relevant technologies shaping this segment include metal and polymer 3D printing, which are revolutionizing how aerospace components are designed and manufactured.

Future Outlook

The Aerospace Additive Manufacturing Market is poised for significant growth from 2024 to 2032, with a projected market value increase from approximately $9.97 billion to $36.25 billion, reflecting a robust compound annual growth rate (CAGR) of 20.24%. This growth trajectory is driven by the increasing adoption of additive manufacturing technologies in aerospace applications, including the production of lightweight components, complex geometries, and customized parts that traditional manufacturing methods cannot achieve. As the industry continues to embrace digital transformation, the penetration of additive manufacturing in aerospace is expected to rise, with estimates suggesting that by 2032, over 30% of new aircraft components may be produced using additive techniques, up from around 10% in 2024. Key technological advancements, such as improved materials for 3D printing, enhanced printing speeds, and the integration of artificial intelligence in design processes, are expected to further propel market growth. Additionally, supportive government policies aimed at fostering innovation and sustainability in aerospace manufacturing will play a crucial role in shaping the market landscape. Emerging trends, including the shift towards sustainable aviation and the increasing focus on reducing carbon footprints, will also drive demand for additive manufacturing solutions that enable more efficient production processes. As the aerospace sector continues to evolve, the adoption of additive manufacturing will not only enhance operational efficiencies but also redefine the future of aircraft design and manufacturing.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2023 | USD 8.29 Billion |

| Growth Rate | 20.24% (2024-2032) |

Aerospace Additive Manufacturing Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.