- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

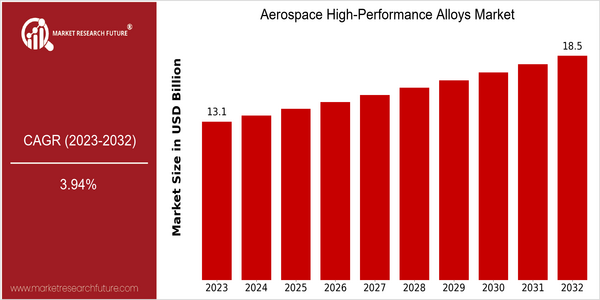

Aerospace High Performance Alloys Market Size Snapshot

| Year | Value |

|---|---|

| 2023 | USD 13.07 Billion |

| 2032 | USD 18.5 Billion |

| CAGR (2024-2032) | 3.94 % |

Note – Market size depicts the revenue generated over the financial year

The Aerospace High Performance Alloys Market is valued at around $13.07 billion in 2023, and is expected to reach $18.49 billion by 2032. This represents an annual growth rate (CAGR) of 4.09 % from 2024 to 2032. The expansion of the market is attributed to the increasing demand for lightweight and durable materials in the aerospace industry, driven by the need for fuel efficiency and improved performance in aircraft design. High-strength alloys are becoming increasingly essential in modern aircraft construction. Technological innovations, such as the development of new alloys and manufacturing methods, are also expected to drive market growth. The aircraft industry is investing heavily in research and development to produce high-strength materials that can withstand extreme temperatures and maintain their strength under extreme pressures. Companies such as Airbus and Boeing are investing in research and development to produce high-strength materials that can withstand extreme temperatures and maintain their strength under extreme pressures. Strategic alliances and collaborations between the leading companies, such as Alcoa and ATI, are expected to accelerate innovation and increase production capacity. These initiatives not only enhance the products but also enable companies to capitalize on the growing demand for advanced materials in the aerospace industry.

Regional Deep Dive

The Aerospace High-Performance Alloys Market is expected to grow at a fast pace in the coming years, driven by the rising demand for lightweight, strong materials in the aerospace industry. The North American region leads the market in terms of technological advancements and innovation, with the presence of a large number of leading manufacturers and research institutes. Europe focuses on the issue of regulatory compliance, while Asia-Pacific is experiencing rapid industrialization and development of its own aerospace industry. The Middle East and Africa are emerging markets with high growth potential, with government support to develop their own aerospace industry. Latin America, although still in the developing stage, is gradually entering the global supply chain, influenced by foreign investments and cooperation.

North America

- In the United States, the government has stepped up research and development in the field of aeronautics, especially in the field of advanced materials. It is hoped that this will further develop the capabilities of high-speed alloys.

- With the advent of additive manufacturing, it has been possible to produce high-performance materials, and to improve the design and the manufacturing efficiency.

- The North American market is influenced by the same requirements of lightness and the economy of fuel. This leads to the use of light alloys which improve the performance of the aircraft.

Europe

- The European Community’s Green Deal encourages the use of high-performance alloys, which reduce the impact on the environment.

- Airbus has begun a programme of development of new alloys whose performance will be improved while keeping within the limits imposed by the regulations on exhaust emissions.

- The universities and the industrialists are also working together, as in the case of the partnership between the University of Sheffield and Rolls-Royce, aimed at developing the technology of alloys.

Asia-Pacific

- The China 2025 plan for a booming aerospace industry will drive up the demand for superalloys, which will be used in both civil and military aircraft.

- The new Make in India program, which is encouraging the local production of aircraft materials, especially high-strength alloys, is a sign of the growing importance of India in this field.

- The industry is undergoing a boom. Foreign direct investment in aircraft manufacture is increasing, and Japanese companies like Mitsubishi Heavy Industries are expanding their operations to meet growing demand.

MEA

- The UAE's Vision 2021 program, which aims at developing a competitive aeronautical industry, will lead to an increased investment in high-tech alloys for aircraft construction.

- In the interest of its own aircraft industry, which is growing rapidly, the government is investing large sums in the National Industrial Development and Logistics Program, which includes the development of new materials.

- The unique geographical position of the region favours the collaboration of local companies with the leading aeronautical groups, and thus the development of high-performance alloys.

Latin America

- Embraer is working on the development of new materials, such as high-strength alloys, to improve the performance of its aircraft.

- Increasingly the region is collaborating with foreign companies in the field of aeronautics, transferring new technology and adopting high-performance alloys.

- Government initiatives to boost the aircraft industry, such as tax breaks for manufacturers, are expected to stimulate the market for high-strength alloys.

Did You Know?

“High-performance alloys are able to withstand extreme temperatures and pressures, which is why they are used in the field of aeronautics, where safety and performance are paramount.” — Aerospace Materials and Processes, 2023

Segmental Market Size

The Aerospace High-Performance Alloys business unit plays a key role in the development of the aircraft industry. It is characterized by a high degree of stability and by a growing demand for lightweight and durable materials. In this field, the need for increased fuel efficiency, the need for lower emissions, and the development of new alloys with improved properties in extreme conditions are all driving forces. These are necessary for the manufacturers to optimize the design and operating efficiency of the aircraft.

The high-tech alloy is currently in a mature stage of development, and the leading aircraft manufacturers such as Airbus and Boeing have incorporated it into the latest models of their aircraft. Its main applications are in the engine, in the wing structure and in the landing gear, where it is replacing the traditional materials such as titanium and nickel-based superalloys. As the sustainable development and green aviation trends continue to grow, the demand for such materials is on the rise. The reason is that they contribute to reducing the weight of the aircraft and therefore to improved fuel economy. In addition, innovations in additive manufacturing and advanced metallurgy are influencing the development of this field, enabling the production of complex shapes and the enhancement of material properties.

Future Outlook

The market for high-strength metals is a specialized area of the metallurgical industry. The global market for high-strength metals is a specialized area of the metallurgical industry. The growing demand for lightweight and durable materials in the aircraft industry, prompted by the industry's focus on fuel efficiency and the environment, will support the growth of the market. The use of high-strength metals, mainly nickel and nickel-based alloys, will increase substantially, and penetration rates are expected to reach up to 30% of the total aircraft material consumption by 2032, up from an estimated 20-23% in 2023.

Additive manufacturing and advanced alloys are expected to further improve the performance characteristics of these materials, which will make them more attractive for a wider range of applications, including commercial aviation, military, and space exploration. The government's support for innovation and sustainable development in the field of aviation will also support the growth of the market. The increasing use of recycled materials in the manufacture of alloys and the development of new alloys with superior properties will also play a major role in shaping the market. High-performance alloys will be able to keep up with the development of the industry.

Aerospace High Performance Alloys Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.