- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

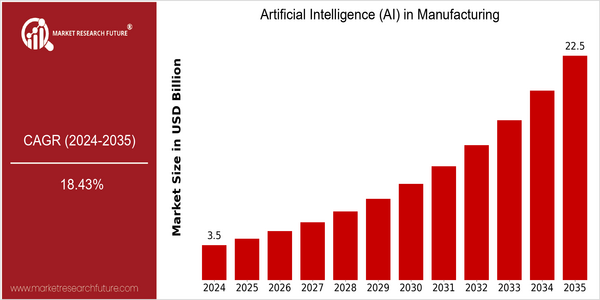

| Year | Value |

|---|---|

| 2024 | USD 3.5 Billion |

| 2035 | USD 22.5 Billion |

| CAGR (2025-2035) | 18.43 % |

Note – Market size depicts the revenue generated over the financial year

Artificial intelligence in manufacturing is expected to reach $22.5 billion by 2035. This is a remarkable growth of 18.43% between 2025 and 2035, indicating a strong demand for artificial intelligence in the manufacturing industry. The main reasons for the growing interest in artificial intelligence are the need for better efficiency, improved maintenance and quality control, and the need for manufacturers to keep up with the competition. The integration of machine learning, robotics and the Internet of Things will further increase this growth. The companies Siemens, GE and IBM are at the forefront of this transformation and are investing heavily in artificial intelligence and in strategic alliances to develop their offerings. For example, Siemens has been developing its own artificial intelligence solutions for smart manufacturing, while GE has been focusing on the use of big data for the optimization of production processes. These initiatives not only highlight the potential of artificial intelligence in the field of smart manufacturing, but also the strategic importance of cooperation and investment in the future.

Regional Market Size

Regional Deep Dive

Artificial intelligence (AI) in manufacturing is experiencing a considerable growth across the globe, owing to the advancement in technology, automation, and the need for efficiency. Each region has its own unique characteristics based on its economic environment, regulatory framework, and cultural attitudes towards the use of technology. North America is leading the way in innovation and investment. Europe is more focused on regulatory compliance and sustainable development. Asia-Pacific is rapidly adopting AI to enhance its manufacturing capabilities. Middle East and Africa is slowly embracing AI, supported by government initiatives. Latin America is also exploring the use of AI to boost its manufacturing productivity.

Europe

- The European Union's AI Act is shaping the regulatory landscape, emphasizing ethical AI use in manufacturing, which is prompting companies to adopt responsible AI practices, particularly in countries like Germany and France.

- Innovations in AI-driven robotics are being spearheaded by companies such as ABB and KUKA, which are developing collaborative robots (cobots) that work alongside human workers to improve efficiency and safety in manufacturing environments.

Asia Pacific

- China is rapidly advancing its AI capabilities in manufacturing, with government initiatives like 'Made in China 2025' promoting the integration of AI technologies to enhance production efficiency and quality.

- Japanese firms, such as Fanuc and Mitsubishi Electric, are leading the way in AI-powered automation solutions, focusing on smart factories that leverage IoT and AI for real-time data analysis and decision-making.

Latin America

- Brazil is emerging as a key player in AI for manufacturing, with initiatives like the Brazilian AI Strategy encouraging the development of AI applications to improve industrial processes and competitiveness.

- Mexican manufacturers are increasingly adopting AI technologies to optimize supply chains and production processes, driven by partnerships with tech companies and government support for digital transformation.

North America

- The U.S. is witnessing a surge in AI adoption in manufacturing, with companies like General Electric and Siemens investing heavily in AI-driven predictive maintenance solutions to reduce downtime and enhance productivity.

- The recent Infrastructure Investment and Jobs Act has allocated significant funding for advanced manufacturing technologies, including AI, which is expected to accelerate the integration of AI in manufacturing processes across various sectors.

Middle East And Africa

- The UAE's National Strategy for Artificial Intelligence aims to position the country as a global leader in AI by 2031, fostering investments in AI technologies for manufacturing and other sectors.

- South Africa is seeing a rise in AI startups focused on manufacturing solutions, with initiatives like the Fourth Industrial Revolution (4IR) strategy promoting the adoption of AI to enhance productivity and competitiveness.

Did You Know?

“By 2025, it is estimated that AI could contribute up to $15.7 trillion to the global economy, with manufacturing being one of the key sectors benefiting from this transformation.” — PwC Global Economic Outlook

Segmental Market Size

Artificial intelligence in manufacturing plays a vital role in enhancing productivity and efficiency and is currently experiencing considerable growth. The need for automation to reduce labour costs and increase precision is driving demand for automation. The push for smart manufacturing is also driving the need for data-driven solutions that can be used to make better decisions. Furthermore, regulatory policies that aim to improve efficiency and the environment are driving demand for AI. Artificial intelligence is in various stages of development. Many companies are still in the pilot phase, but some, such as Siemens and General Electric, have already rolled out their AI solutions across their operations. North America and Europe, where advanced manufacturing is commonplace, are leading the way in terms of the adoption of AI. In terms of applications, the main ones are in the fields of predictive maintenance, quality control and supply chain management. For example, Bosch is using real-time monitoring. Artificial intelligence in manufacturing is expected to grow strongly, mainly because of the trend towards Industry 4.0 and the drive for greater efficiency and the drive towards greater sustainability. Machine learning, the Internet of Things and robots are the main technological developments driving the market.

Future Outlook

Artificial intelligence is a new technology. Artificial intelligence will be the key to the future of the world economy. Artificial intelligence has become an increasingly important part of the economy, with a growing number of businesses using it to increase productivity, reduce costs, and improve product quality. In 2035, it is expected that artificial intelligence will be applied to more than seventy percent of manufacturing processes, which will transform the old production mode, and that the real-time decision-making will be based on big data and machine learning. The development of smart factories and the Internet of Things will be the most important driving forces. The combination of IoT and artificial intelligence can help to optimize the supply chain, increase automation, and reduce downtime. In addition, the government's encouragement of innovation and investment in artificial intelligence will help to accelerate the spread of the technology. The rise of the robot and the development of quality control systems will also play an important role in the future of manufacturing.

Artificial Industrial in Manufacturing Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.