Automotive Composite Suspension Component Market Overview

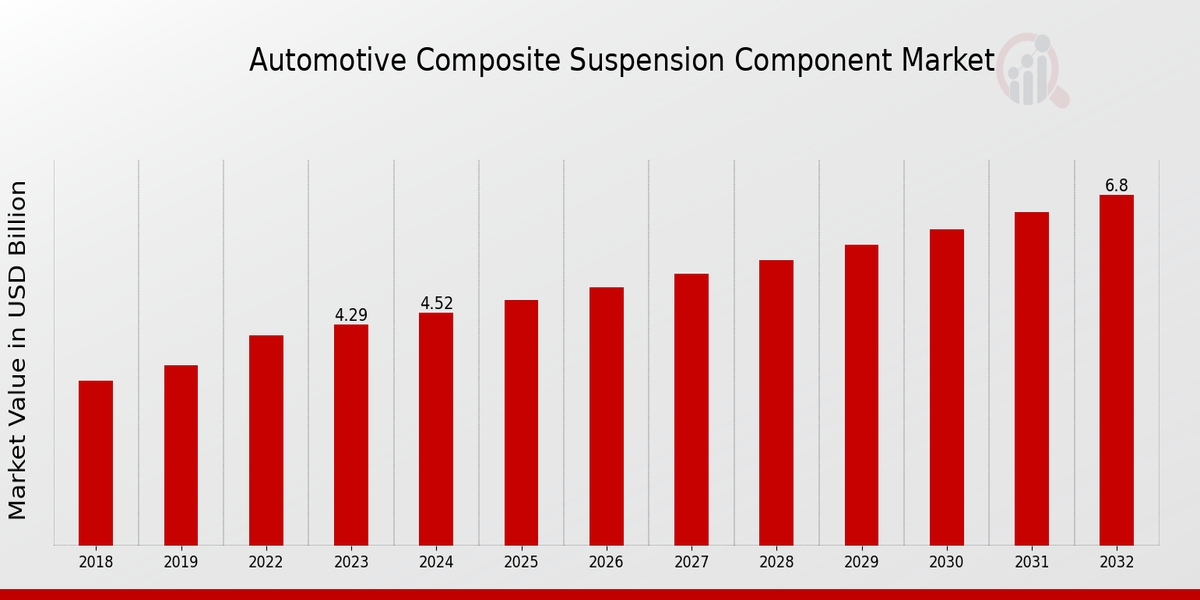

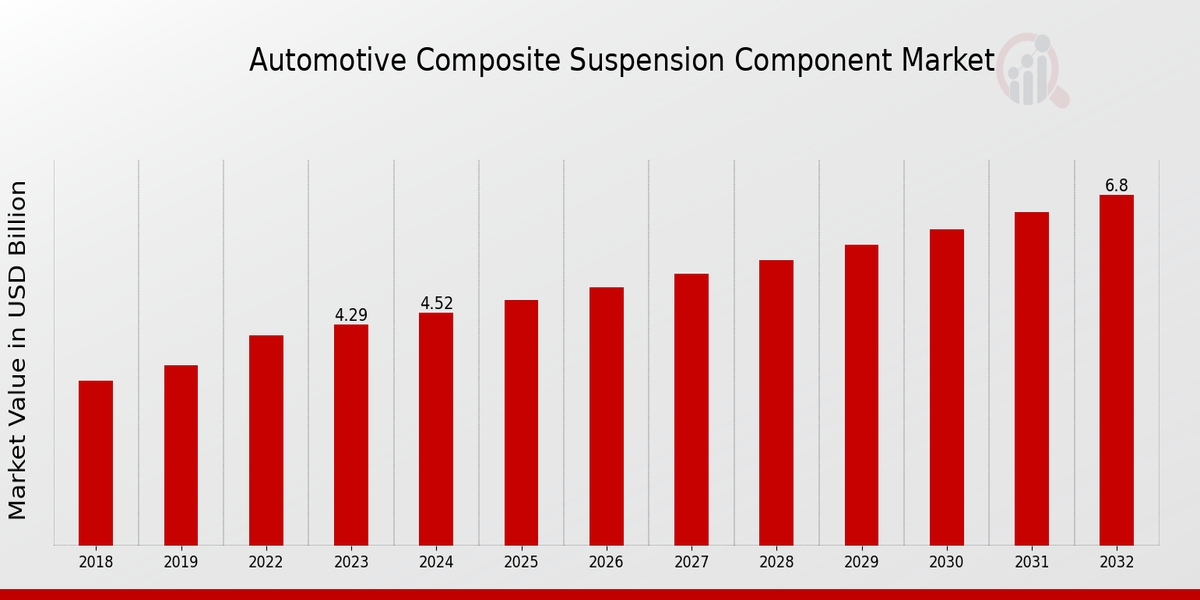

As per MRFR analysis, the Automotive Composite Suspension Component Market Size was estimated at 4.08 (USD Billion) in 2022. The Automotive Composite Suspension Component Market is expected to grow from 4.29 (USD Billion) in 2023 to 6.8 (USD Billion) by 2032. The Automotive Composite Suspension Component Market CAGR (growth rate) is expected to be around 5.24% during the forecast period (2024 - 2032).

Key Automotive Composite Suspension Component Market Trends Highlighted

Numerous reasons are driving the huge expansion of the automotive composite suspension component market. The growing need for lightweight materials to improve vehicle emissions and fuel efficiency is one of the main factors propelling the market.

The use of composite materials has increased as automakers work to satisfy strict environmental standards and consumer demands for sustainability.

Furthermore, composite suspension components are becoming a competitive option to conventional materials due to increased performance characteristics brought about by developments in manufacturing methods.

Demand for cutting-edge suspension systems that can accommodate their distinct weight distribution and driving characteristics is also being boosted by the growing popularity of electric and hybrid cars.

There are several opportunities in the market for automotive composite suspension components, especially in the field of research and development. Businesses may meet the changing demands of the automobile industry by investing in the development of innovative composites with higher strength-to-weight ratios.

Collaborations between OEMs and material suppliers are also paving the way for innovative product offerings that meet the performance expectations of modern vehicles. The shift towards automation and the advent of smart manufacturing practices present further opportunities for optimizing production processes and enhancing product quality.

Recent trends indicate a growing inclination towards the integration of advanced technologies such as artificial intelligence and machine learning in the design and testing of composite suspension systems. Such trends not only improve design efficiency but also bolster the performance and reliability of suspension components.

Furthermore, the increasing adoption of sustainability practices in supply chain management reflects a shifting mindset in the automotive industry, focusing on reducing the environmental impact of manufacturing processes.

Overall, the market for automotive composite suspension components is poised for robust growth driven by a convergence of technological advancements, regulatory pressures, and evolving consumer preferences.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Automotive Composite Suspension Component Market Drivers

Increased Demand for Lightweight Materials

The Automotive Composite Suspension Component Market is primarily driven by the increasing demand for lightweight materials in automotive manufacturing. As the automotive industry focuses on enhancing fuel efficiency and reducing carbon emissions, the adoption of composite materials in suspension components has become crucial. These lightweight composites not only contribute to a reduction in the overall weight of vehicles but also improve handling performance and driving dynamics.

With an expanding emphasis on sustainability and environmental responsibilities, manufacturers are seeking innovative solutions that align with these objectives. The ability of composite materials to withstand high stress while being lighter than traditional suspension components makes them an attractive option for automotive manufacturers.

Furthermore, as consumer preferences lean towards fuel-efficient and eco-friendly vehicles, the demand for lightweight composite suspension components is further reinforced.

The continuous advancements in composite technology, leading to better performance characteristics, also influence the trajectory of the Automotive Composite Suspension Component Market. Stakeholders in the automotive sector increasingly recognize that investing in composite materials can yield significant long-term benefits, including compliance with stricter regulatory standards and meeting the growing consumer demand for greener vehicles.

This trend is expected to continue shaping the market landscape well into the future, further promoting the application of advanced composites in automotive suspension systems.

Growth in Electric and Hybrid Vehicle Production

The growth of electric and hybrid vehicle production significantly propels the Automotive Composite Suspension Component Market. As these vehicle types are designed to be more energy-efficient, manufacturers are focusing on using advanced materials that contribute to overall weight reduction, ultimately enhancing their performance.

By incorporating composite suspension components, automakers can achieve better energy utilization while complying with the stringent performance requirements associated with electric and hybrid vehicles.

The shift towards electrification not only opens new market opportunities but also necessitates the adoption of innovative materials that provide the necessary rigidity and structural integrity needed in modern suspension systems.

Technological Advancements in Composite Materials

Technological advancements in composite materials significantly drive the Automotive Composite Suspension Component Market. Innovations in manufacturing processes, such as improved molding techniques and enhanced material formulations, enable the production of more durable and reliable composite components. These advancements have led to composite materials that can meet the demanding requirements of automotive applications, including resistance to temperature fluctuations and mechanical stress.

As a result, manufacturers are increasingly adopting these advanced composite materials for suspension components, thereby boosting market growth

Automotive Composite Suspension Component Market Segment Insights

Automotive Composite Suspension Component Market Material Type Insights

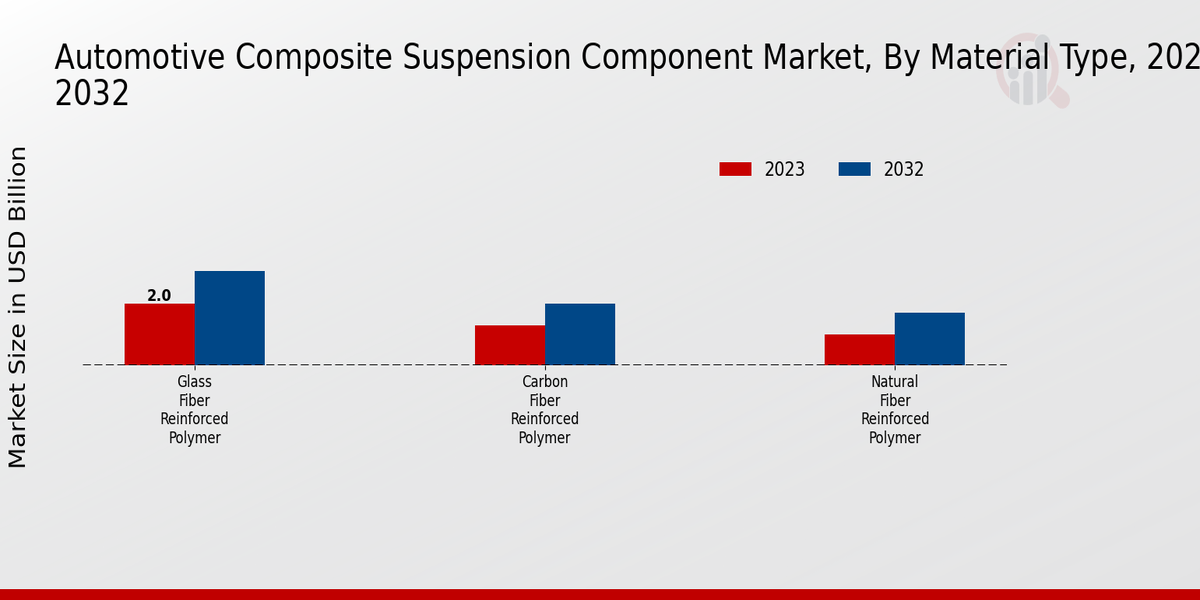

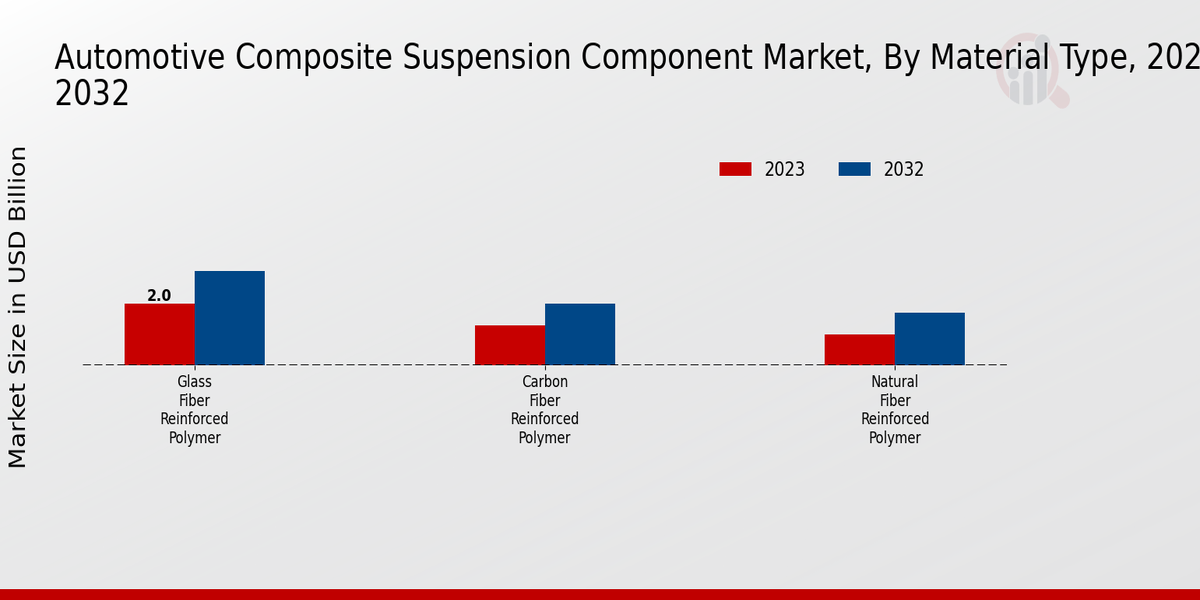

The Automotive Composite Suspension Component Market, segmented by Material Type, reveals noteworthy insights with substantial market values attributed to each material category. In 2023, Glass Fiber Reinforced Polymer dominated this space, holding a significant market value of 2.0 USD Billion. This material was highly favored in automotive applications due to its excellent strength-to-weight ratio, which enhances fuel efficiency and performance in vehicles.

Following closely was Carbon Fiber Reinforced Polymer, which was valued at 1.29 USD Billion in 2023.

This material is revered for its lightweight properties and high strength, making it a crucial component in high-performance vehicles where reducing weight is essential for efficiency and speed.

Finally, Natural Fiber fiber-reinforced polymer stood at a value of 0.99 USD Billion in the same year, and while it has a smaller share, it contributes to sustainable automotive manufacturing practices as an eco-friendly alternative, addressing growing environmental concerns in the industry. This segmentation illustrated the diverse preferences within the Automotive Composite Suspension Component Market, with Glass Fiber Reinforced Polymer holding a majority share and significantly impacting market growth due to its established application and demand.

The varying characteristics of each material also hint at distinct trends within the market, where the shift towards sustainability is gradually elevating the status of Natural Fiber Reinforced Polymer despite its current smaller market presence.

Overall, understanding these material types provided clarity on the Automotive Composite Suspension Component Market statistics and emphasized the importance of innovation and adaptation in material use to meet evolving automotive needs. The growing emphasis on lightweight components across the automotive sector enables cost-effectiveness and energy efficiency, thus driving significant growth across all material types.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Automotive Composite Suspension Component Market Suspension Type Insights

Within the market segmentation, the Suspension Type plays a crucial role, which encompasses Independent Suspension, Dependent Suspension, and Semi-Independent Suspension. Independent Suspension is particularly significant due to its ability to enhance vehicle stability and comfort, making it a preferred choice for many modern vehicles.

On the other hand, Dependent Suspension systems are favored in utility vehicles and trucks due to their robustness and ability to handle heavy load capacities. The semi-independent suspension provides a balance between performance and cost, appealing to a range of vehicle types, particularly in the mid-range price segment.

Overall, the Automotive Composite Suspension Component Market data reflects trends toward lightweight materials and advanced manufacturing technologies that are shaping the industry, while challenges such as high production costs and fluctuating raw material prices persist, presenting both opportunities and hurdles for market participants.

Automotive Composite Suspension Component Market Application Insights

The Application segment of this market comprises various vehicle types, namely Passenger Vehicles, Commercial Vehicles, and Off-Road Vehicles. Passenger Vehicles represent a significant portion of market growth due to an increasing consumer demand for lightweight and fuel-efficient designs, which enhance vehicle performance and reduce emissions.

Commercial Vehicles, also crucial to the Automotive Composite Suspension Component Market, play an important role in logistics and transportation, benefiting from lightweight components that improve payloads and fuel economy.

Off-road vehicles, while occupying a niche market, are vital for adventure and utility purposes, requiring robust suspension components capable of withstanding rugged terrains. This diversification among Applications contributes to the Automotive Composite Suspension Component Market revenue and its overall dynamics, fostering opportunities driven by innovative materials and technological advancements.

The increasing emphasis on sustainability is further fueling adoption across all vehicle categories, transforming the landscape and pushing the boundaries of existing composites.

As the market continues to evolve, understanding this segmentation is essential for stakeholders looking to harness the potential of this growing industry.

Automotive Composite Suspension Component Market Component Function Insights

The Component Function segment of the Automotive Composite Suspension Component Market plays a critical role in the overall performance and safety of vehicles. This segment includes essential components such as shock absorbers, springs, and control arms, which contribute to the vehicle's ride quality and handling capabilities. Shock absorbers are particularly vital as they help control vehicle stability and improve overall safety during various driving conditions.

Springs are also significant as they bear the vehicle's weight and ensure the suspension system operates effectively, allowing for better control and comfort. Control arms further enhance vehicle handling and ensure accurate alignment of the suspension system, making them indispensable in the automotive manufacturing process.

The increasing focus on lightweight materials and advanced composite solutions has driven notable shifts in this sector, aligning with the broader trends of sustainability and efficiency within the automotive industry. Growing investment in research and development is expected to create further opportunities within these components as manufacturers aim to leverage innovative technologies for enhanced performance.

The robust Automotive Composite Suspension Component Market statistics underscore the importance and dynamic nature of this market segment.

Automotive Composite Suspension Component Market Manufacturing Process Insights

The Automotive Composite Suspension Component Market is driven by advancements in manufacturing processes that enhance component performance and durability.

The Manufacturing Process segment is integral to this market, encompassing various techniques such as Hand Lay-Up, Resin Transfer Molding, and Pultrusion, each contributing uniquely to the production of composite materials. Hand Lay-Up is favored for its flexibility and cost-effectiveness, allowing for customized designs in low-volume production.

Resin Transfer Molding offers high-quality finishes and is increasingly popular due to its ability to produce complex geometries efficiently. Pultrusion stands out for its ability to create continuous lengths of reinforced composite material, proving to be especially significant in high-strength applications. The potential for expanding these manufacturing techniques is substantial.

The focus on innovation, combined with an increasing demand for lightweight and high-performance suspension components, underscores the importance of optimizing manufacturing processes to enhance the overall Automotive Composite Suspension Component Market revenue and statistics.

Automotive Composite Suspension Component Market Regional Insights

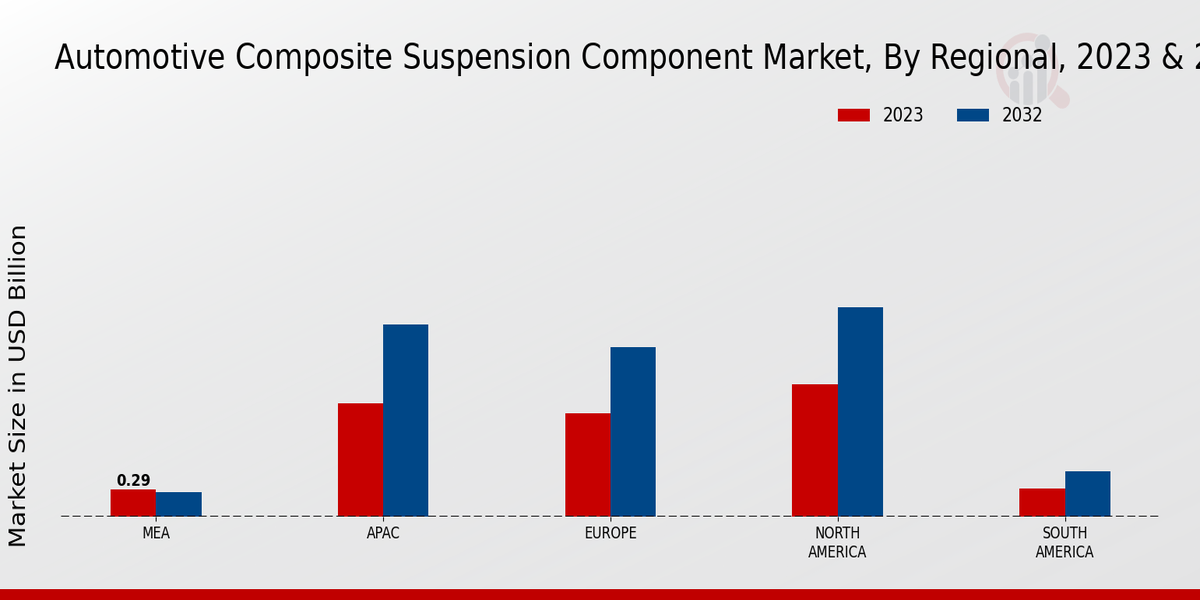

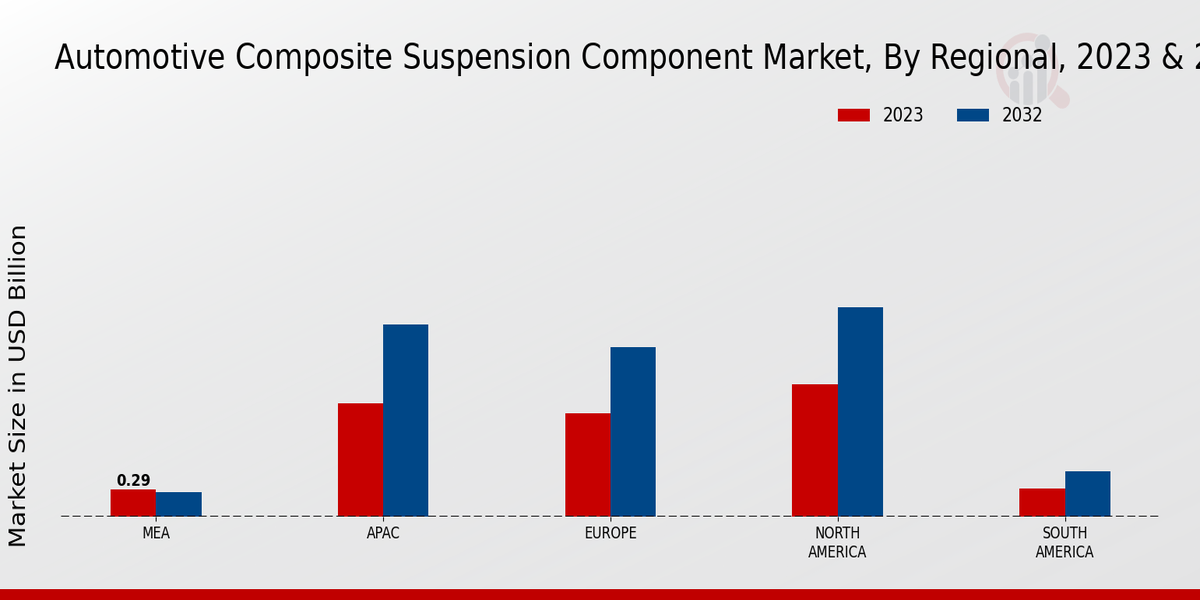

North America held a majority share with a valuation of 1.4 USD Billion, reflecting its robust automotive industry and innovation in composite materials. The Asia Pacific region followed closely, valued at 1.2 USD Billion, driven by increasing vehicle production and demand for lightweight components, expected to reach 2.04 USD Billion by 2032.

Europe accounted for 1.1 USD Billion in 2023 and exhibits significant growth due to stringent regulatory standards for vehicle efficiency and performance, projected to 1.8 USD Billion by 2032.

South America and the Middle East and Africa showed smaller market valuations at 0.3 USD Billion and 0.29 USD Billion in 2023, respectively, highlighting opportunities for growth as automotive sectors in these regions expand.

Overall, the regional insights of the Automotive Composite Suspension Component Market data indicated growth potential, particularly in the Asia Pacific and Europe, driven by innovation and increasing consumer demand for advanced automotive technologies.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Automotive Composite Suspension Component Market Key Players And Competitive Insights:

The Automotive Composite Suspension Component Market is experiencing significant growth driven by the increasing demand for lightweight, high-performance materials in the automotive industry. As manufacturers strive to enhance fuel efficiency and reduce emissions, the adoption of composite materials in suspension components has gained traction. The competitive landscape is characterized by a range of players, including those focusing on advanced materials research, innovative manufacturing techniques, and collaborations with automotive manufacturers.

Companies are investing in developing composites that not only offer superior mechanical properties but also meet stringent automotive regulations. The market is characterized by a mix of established companies with strong brand recognition and innovative startups that are pushing the boundaries of material science for automotive applications. The emphasis on sustainability and eco-friendliness is also influencing competition, as companies are exploring bio-based composites and recycling processes to meet the growing consumer preference for green technologies.

BASF SE has established a powerful presence in the Automotive Composite Suspension Component Market, leveraging its extensive portfolio of innovative materials and cutting-edge technologies. Renowned for its advanced engineering plastics and composite solutions, BASF SE is committed to helping automakers achieve optimal performance while reducing weight and improving overall efficiency.

The company's strengths lie in its deep understanding of customer needs, which enables it to develop tailored solutions that enhance suspension performance while maintaining durability. Moreover, BASF SE's strong research and development capabilities allow for continuous innovation, ensuring that its offerings remain at the forefront of market trends.

Its network of production and distribution facilities not only enhances its capability to meet demand but also ensures reliability and consistency in delivering high-quality materials, further solidifying its competitive edge in the automotive sector.

Teijin Limited is another key player in the Automotive Composite Suspension Component Market, recognized for its commitment to innovation and sustainability in composite materials. The company's expertise lies in creating high-performance carbon fiber and other advanced composites, which are becoming increasingly important in the automotive industry for their lightweight and strength properties.

Teijin Limited's strengths are built upon its robust research framework, enabling it to develop groundbreaking materials that cater to the evolving needs of automotive manufacturers. The company's focus on sustainable practices and eco-friendly materials aligns with the larger industry trend towards greener automotive solutions.

Furthermore, Teijin Limited maintains strong partnerships with various automotive OEMs, facilitating collaborative projects that drive technology advancement in composite applications for suspension components. Their emphasis on quality and performance has positioned Teijin Limited as a trusted partner within the market, enhancing its competitive stature.

Key Companies in the Automotive Composite Suspension Component Market Include:

- Mitsubishi Chemical Corporation

Automotive Composite Suspension Component Market Developments

Recent developments in the Automotive Composite Suspension Component Market have shown a significant shift towards lightweight materials to enhance vehicle efficiency and performance. Manufacturers are increasingly adopting advanced composite materials to reduce weight without compromising on strength and durability.

Innovations in manufacturing processes, such as resin transfer molding and automated fiber placement, are improving production efficiency and lowering costs. Additionally, the rise of electric vehicles (EVs) has spurred demand for advanced suspension systems that can better manage the distinctive weight distribution of electric drivetrains.

Partnerships between automotive OEMs and materials suppliers are becoming more common, focusing on research and development to meet rising regulations for fuel efficiency and emissions. The integration of smart technologies in suspension systems, aiming for improved driving dynamics and comfort, is also gaining traction.

Overall, as the industry evolves, the emphasis on sustainability and performance is shaping the market landscape, prompting players to stay competitive through technological advancements and strategic collaborations.

Automotive Composite Suspension Component Market Segmentation Insights

Automotive Composite Suspension Component Market Material Type Outlook

- Carbon Fiber Reinforced Polymer

- Glass Fiber Reinforced Polymer

- Natural Fiber Reinforced Polymer

Automotive Composite Suspension Component Market Suspension Type Outlook

- Semi-Independent Suspension

Automotive Composite Suspension Component Market Application Outlook

Automotive Composite Suspension Component Market Component Function Outlook

Automotive Composite Suspension Component Market Manufacturing Process Outlook

Automotive Composite Suspension Component Market Regional Outlook

| Report Attribute/Metric |

Details |

| Market Size 2022 |

4.08(USD Billion) |

| Market Size 2023 |

4.29(USD Billion) |

| Market Size 2032 |

6.8(USD Billion) |

| Compound Annual Growth Rate (CAGR) |

5.24% (2024 - 2032) |

| Report Coverage |

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Base Year |

2023 |

| Market Forecast Period |

2024 - 2032 |

| Historical Data |

2019 - 2023 |

| Market Forecast Units |

USD Billion |

| Key Companies Profiled |

BASF SE, Teijin Limited, Toray Industries Inc., Continental AG, Mitsubishi Chemical Corporation, Futura Industries, DSM Engineering Plastics, Energine, Hexcel Corporation, SABIC, SGL Carbon SE, Zoltek Companies Inc., Solvay SA |

| Segments Covered |

Material Type, Suspension Type, Application, Component Function, Manufacturing Process, Regional |

| Key Market Opportunities |

Lightweight materials adoption Electric vehicle integration Advanced manufacturing processes Sustainability and recycling initiatives Enhanced performance and durability |

| Key Market Dynamics |

Rising demand for lightweight materials Increasing adoption of electric vehicles Enhanced fuel efficiency requirements Growing regulatory support for composites Technological advancements in manufacturing processes |

| Countries Covered |

North America, Europe, APAC, South America, MEA |

Frequently Asked Questions (FAQ):

The Automotive Composite Suspension Component Market is projected to reach a valuation of 6.8 USD Billion by 2032.

The expected CAGR for the Automotive Composite Suspension Component Market from 2024 to 2032 is 5.24.

By 2032, North America is expected to have the largest market size valued at 2.22 USD Billion.

The Carbon Fiber Reinforced Polymer segment is expected to grow to 2.01 USD Billion by 2032.

The Glass Fiber Reinforced Polymer segment is estimated to reach 3.09 USD Billion by 2032.

By 2032, the Natural Fiber Reinforced Polymer segment is forecasted to increase to 1.7 USD Billion.

The Middle East and Africa region is expected to show the smallest increase, projected at 0.26 USD Billion by 2032.

Key players include BASF SE, Teijin Limited, Toray Industries Inc., and Continental AG, among others.

The projected market size for Europe in 2032 is 1.8 USD Billion.

The South American region is expected to grow to 0.48 USD Billion by 2032.