- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

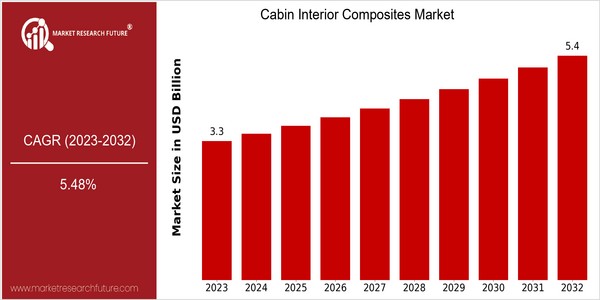

| Year | Value |

|---|---|

| 2023 | USD 3.34 Billion |

| 2032 | USD 5.4 Billion |

| CAGR (2024-2032) | 5.48 % |

Note – Market size depicts the revenue generated over the financial year

The market for aircraft cabin interior composites is expected to be worth about $ 3.34 billion in 2023, and to reach $ 5.41 billion by 2032, at a CAGR of 5.48 percent from 2024 to 2032. The steady increase in demand for lightweight, durable materials that enhance the overall passenger experience and contribute to the fuel economy of the aviation industry is expected to continue. This has led to an increased preference for advanced composite materials, which have the following advantages: Lighter in weight, stronger in impact, and more resistant to chemical attack. This market is driven by a number of factors, including an increasing emphasis on fuel economy, the tightening of regulations on aircraft emissions, and a growing trend towards sustainable aviation practices. In addition, technological developments in the composites industry, such as improved resin systems and new fabrication techniques, will continue to drive this market. Strategic initiatives undertaken by industry players, such as Hexcel, Toray Industries, and Solvay, to develop the next generation of composite materials will also continue to drive this market. These efforts will not only enhance the product offerings of these companies, but will also enable them to strengthen their position in the market for aircraft cabin interior solutions.

Regional Market Size

Regional Deep Dive

The market for composite materials for aircraft interiors is growing at a fast pace in various regions, as the demand for lightweight materials to reduce fuel consumption and emissions in the aircraft industry is on the rise. Each region has its own characteristics, which are influenced by local regulations, technological developments and market conditions. North America leads in terms of innovation and production capacity, while Europe focuses on the environment and regulatory compliance. The Asia-Pacific region is growing fast because of the increasing number of passengers and production capacities, while the Middle East and Africa are emerging markets with growth potential due to increasing investment in the aviation industry. Latin America, though smaller, is also growing slowly, as the local airlines are modernizing their fleets.

Europe

- European manufacturers are focusing on sustainable materials, with companies like Airbus leading initiatives to develop bio-composites for cabin interiors, aligning with the EU's Green Deal objectives.

- The European Union's stringent regulations on emissions are pushing airlines to invest in lightweight composite materials, which are expected to significantly reduce overall aircraft weight and improve fuel efficiency.

Asia Pacific

- The Asia-Pacific region is witnessing a surge in air travel, with companies like Mitsubishi Aircraft Corporation investing in advanced composite materials for their new aircraft models to meet growing demand.

- Government initiatives in countries like China and India are promoting the development of local aerospace manufacturing capabilities, which is expected to increase the adoption of cabin interior composites in the region.

Latin America

- Latin America is gradually modernizing its aviation sector, with airlines like LATAM Airlines investing in new aircraft that utilize composite materials for improved passenger comfort and operational efficiency.

- Government support for the aviation industry in countries like Brazil is fostering partnerships with composite manufacturers, which is expected to enhance local production capabilities.

North America

- The North American market is heavily influenced by major aerospace manufacturers such as Boeing and Airbus, which are increasingly adopting composite materials to enhance aircraft performance and reduce weight.

- Recent regulatory changes by the FAA have encouraged the use of advanced composite materials in aircraft interiors, promoting innovation and safety standards in the industry.

Middle East And Africa

- The Middle East is seeing significant investments in aviation infrastructure, with companies like Emirates and Qatar Airways modernizing their fleets, leading to increased demand for advanced cabin interior composites.

- Regulatory bodies in the region are beginning to adopt international standards for aircraft materials, which is expected to drive the adoption of high-performance composites in cabin interiors.

Did You Know?

“Did you know that composite materials can reduce the weight of aircraft interiors by up to 30%, significantly improving fuel efficiency and reducing carbon emissions?” — Aerospace Composite Materials Report 2023

Segmental Market Size

In the past decade, the composites market for the interiors of aircraft has grown steadily. The main reason for this is the increasing demand for lightweight materials that improve fuel economy and reduce emissions. This has been accompanied by stricter regulations and the development of composites manufacturing technology, which has led to greater design freedom and performance. In the latest aircraft, such as the Airbus A330 and the Boeing 787-9, composites have been used extensively in the interiors to achieve a weight reduction and improved comfort for passengers. The current state of the art in the use of composites in the interiors of aircraft is one of extensive deployment, with notable examples such as the Boeing 787 Dreamliner. The main applications are in the cabin walls, overhead bins and seat components, where composites offer the required strength and appearance. The trend towards sustainable aviation and government regulations that require the reduction of carbon dioxide emissions are also driving growth in this area. In addition, the development of new resin systems and manufacturing methods, such as 3D printing and automated fibre placement, will open up new possibilities for the manufacture of cabin interiors and reduce the costs.

Future Outlook

The cabin composites market is expected to increase from $3.34 billion to $5.4 billion by 2032, at a CAGR of 5.48 %. This growth is due to the growing demand for lightweight materials in the aerospace industry, which will enhance fuel efficiency and reduce emissions. As the focus of the industry on sustainable development increases, the use of advanced composite materials in the cabin interiors is expected to increase, leading to better performance and comfort for passengers. The composite materials used in the cabin interiors will increase from 20 % in 2023 to 30 % in 2032, due to the continuous development of the science and technology of materials. The development of bio-based composites and the improvement of manufacturing processes are expected to boost market growth. The use of sustainable materials will be encouraged by the regulatory policies to reduce the impact of aviation on the environment. The integration of smart technology into the design of the cabin and the growing emphasis on the passenger experience will also shape the market. Consequently, the cabin composites market is expected to be dynamic and innovation-driven, and companies need to be ready to seize the opportunities of this growth phase.

Cabin Interior Composites Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.