- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

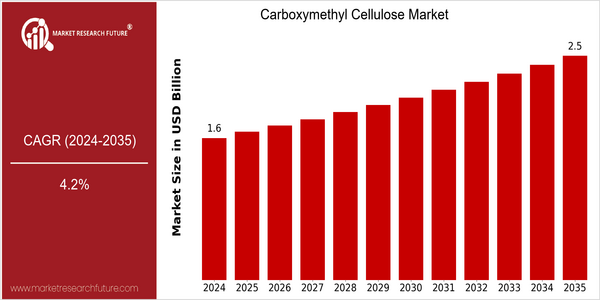

Carboxymethyl Cellulose Market Size Snapshot

| Year | Value |

|---|---|

| 2024 | USD 1.59 Billion |

| 2035 | USD 2.5 Billion |

| CAGR (2025-2035) | 4.2 % |

Note – Market size depicts the revenue generated over the financial year

The Carboxymethyl-Cellulose (CMC) market is expected to reach a steady growth with a current market size of $ 1,590 million in 2024, and reach $ 2,549 million by 2035. The CAGR is 4.2% from 2025 to 2035. The increasing demand for CMC in various industries such as food, pharmaceuticals and cosmetics is the main reason for this expansion. The versatility of CMC as a thickener and stabilizer makes it a popular product in the market. Technological developments and innovations in production methods will further drive the CMC market. The quality and functionality of CMC is being improved through research and development, thereby increasing the application areas and the market share. The major market players such as Dow Chem, Ashland and AkzoNobel are constantly working on strategic alliances and product launches to strengthen their market position. Recent collaborations aimed at developing sustainable CMC solutions illustrate the industry's commitment to meeting changing consumer preferences and regulatory standards, thereby creating a robust growth environment for the CMC market.

Regional Deep Dive

The market for carboxymethyl cellulose (CMC) is growing rapidly across the globe. This growth is primarily a result of the growing demand from the food, pharmaceutical, and cosmetic industries. The market is characterized by the presence of leading manufacturers and a growing demand for natural and organic products in North America. Europe is characterized by a high level of safety and quality requirements. Asia-Pacific is characterized by rapid industrialization and urbanization, which results in a growing demand for CMC in various applications. Middle East and Africa (MEA) are gradually introducing CMC in various industries, supported by increasing infrastructure. In Latin America, health and hygiene are becoming increasingly important, which also promotes the development of the CMC market.

North America

- Recent approval by the Food and Drug Administration of the United States has increased the use of CMC in the food industry and has contributed to the growth of the market.

- Among the companies investing in R&D are the large companies Ashland Global Holdings and The Dow Chemical Company. These companies are developing new CMC products, which will significantly expand the market.

- In a word, the trend is for a more sustainable industry, with an emphasis on the sustainable exploitation of raw materials and on the use of sustainable production methods, and the desire of consumers for more sustainable products.

Europe

- The European Food Safety Authority (EFSA) has introduced stricter regulations on food additives. This has led to greater scrutiny and innovation in the formulation of CMCs in order to meet safety requirements.

- In this region, companies such as AkzoNobel and CP Kelco are promoting the development of CMC products based on bio-materials.

- The growing trend towards clean label in Europe is pushing manufacturers to seek natural alternatives to synthetic additives, which has increased the demand for CMC derived from renewable sources.

Asia-Pacific

- In the East, the rapid development of cities and the rapidly increasing middle class, especially in China and India, are responsible for a large increase in the demand for CMC in the food and cosmetics industries.

- It is generally believed that the use of enzymatic technology can improve the quality and functionality of CMC, and thus make it more competitive in the world market.

- Government policy initiatives for a new and improved pharmaceutical industry in India are opening up new opportunities for the application of CMC to drug formulations and delivery systems.

MEA

- In the Gulf countries, especially in the countries of the Gulf Cooperation Council, there is a great investment in construction projects. This will increase the demand for mastic cements and mortars, which are manufactured from CMC.

- In addition, the local companies are also working with the international companies to increase the production capacity of CMC and meet the demand of CMC in various sectors, especially food and pharmaceuticals.

- The establishing of regulations for the use of CMC and other food additives is a matter of concern for the authorities in the region.

Latin America

- The increasing health consciousness of the population in Brazil and Mexico is driving demand for guar gum as a thickening and stabilizing agent in low-calorie and healthy food.

- During the period from 1860 to 1870, the products of the CMC industries, which were largely imported, were undergoing a rapid evolution in style and in quality.

- CMC, a natural substance, is used in the soil, in the fertilization and in the protection of the plant.

Did You Know?

“CMC is not only used as a food preservative, but also plays an important role in the pharmaceutical industry, where it is used as a thickener and binder in various pharmaceutical preparations.” — International Journal of Pharmaceutics

Segmental Market Size

The Carboxymethyl Cellulose (CMC) market is playing a major role in many industries, especially in the food, pharmaceutical and cosmetics industries, and is currently experiencing a steady growth. Among the main reasons for this is the growing consumer preference for natural and clean label products, which CMC can help to stabilize and thicken. CMC is also favored by regulations promoting the use of safe and natural food additives.

CMC is now widely used, and companies such as Ashland and Dow are the leaders in both research and development. The most important applications are in gluten-free foods, where it helps to improve the texture, and in pharmaceuticals, where it is used as a tablet binder. And as the trend towards plant-based diets and sustainable development increases, so does the demand for CMC. The development of the industry is largely determined by new extraction methods and bioprocessing. The result is that production is becoming more efficient and more sustainable.

Future Outlook

Carboxymethyl cellulose is a cellulose derivative that can be used as a binder for various materials. The CMC market is expected to grow at a CAGR of 4.2% from 2024 to 2035. The growth of this market is mainly driven by the growing demand for CMC in various industries such as food and beverage, pharmaceuticals, and cosmetics. In the meantime, consumers are increasingly demanding natural and healthy ingredients, and CMC's versatility as a thickener, stabilizer, and emulsifier is expected to make it more competitive in the market. CMC penetration in the food and beverage industry is expected to reach about 30% in 2035, driven by the clean label trend and the growing demand for gluten-free and vegetarian products.

CMC Market: Technological Advancements and Policy Drivers are expected to further shape the CMC market landscape. The introduction of new manufacturing processes, such as more efficient and sustainable manufacturing, will enhance the quality and lower the cost of CMCs, thereby making them more available for a wider range of applications. The use of natural additives in food will also be a major growth driver, as manufacturers seek to comply with the increasingly stringent safety and quality standards. Also, the growing demand for CMCs in sustainable packaging solutions and its application in the pharmaceutical industry for drug delivery systems will continue to boost the CMC market. In conclusion, the CMC market will continue to grow in the coming years, driven by the changing preferences of consumers and the technological advancements.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 6% (2020-2030) |

Carboxymethyl Cellulose Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.