Research Methodology on Coil Coating Market

Introduction:

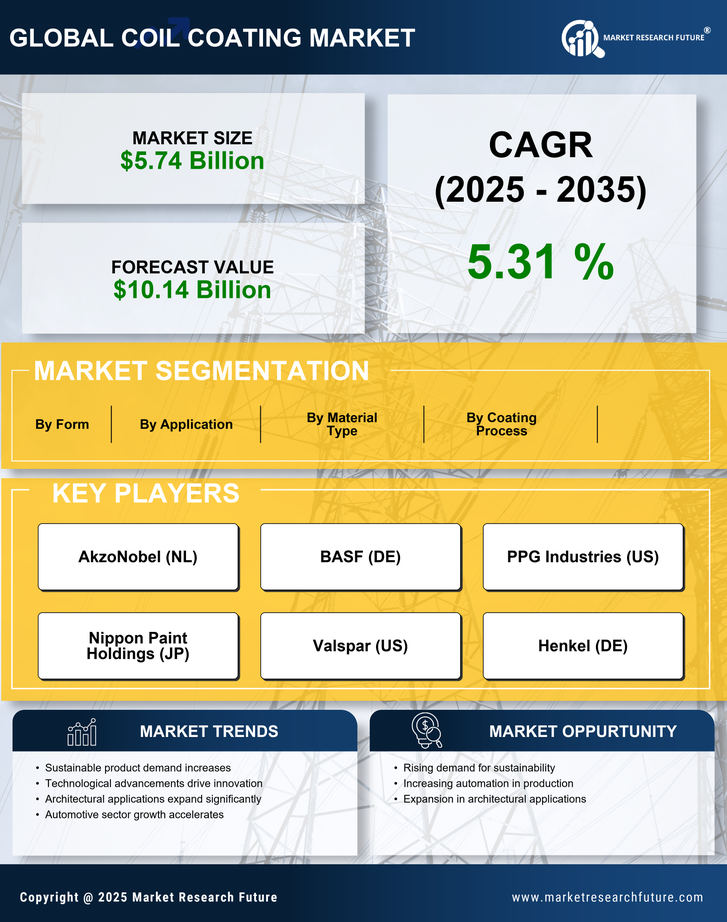

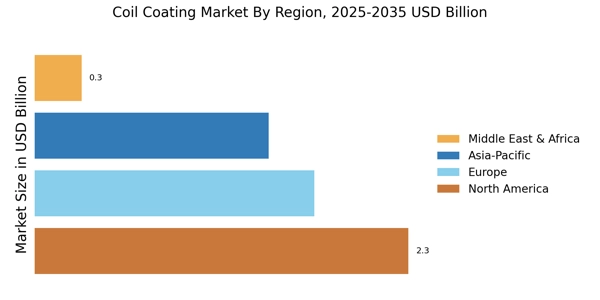

The Coil Coating Market study provides an in-depth analysis and insights into the global Coil Coating market which is anticipated to witness a strong growth rate over the forecast period from 2025 to 2035. It also offers an outlook on the market dynamics across five major regions including North America, Europe, Asia–Pacific, the Middle East & Africa, and South America.

Objective:

The objective of this research is to identify the current trends and future prospects of the global Coil Coating market and to gain an in-depth understanding of the key drivers and restraints that have a strong impact on the market. The research also provides detailed insights on the competitive landscape i.e. the manufacturers, technology trends and business strategies adopted by the top players in the market.

Research Methodology:

This research project combines both primary and secondary research data to analyze the global Coil Coating market. Primary data refers to research conducted at the field level via surveys, interviews and questionnaires. The secondary research data include reliable sources such as industry journals, magazines, white papers, conference proceedings, market reports, government publications and others.

The primary data collected was analyzed using qualitative and quantitative research techniques. In order to attain an in-depth understanding of the market, the quantitative analysis was performed for different regions, which included North America, Europe, Asia–Pacific, Middle East & Africa, and South America.

To further understand the competitive landscape, a Porter’s Five Forces Analysis was done which provided insights into the bargaining power of buyers & suppliers, threats of new entrants & substitute products, competitive rivalry, and degree of industry concentration.

In addition, an in-depth study was done on the market dynamics such as drivers, restraints and opportunities along with the technological trends and the business strategies adopted by the leading manufacturers.

The secondary research data was collected from reliable sources such as industry journals, magazines, white papers, conference proceedings, market reports, government publications and others. The data was further analyzed using techniques such as Porter’s Five Forces Analysis and SWOT Analysis to gain insights into the industry's performance.

In order to conclude the future prospects of the market, a combination of primary and secondary research data was utilized. This was done by comparing the current market dynamics with those of the past few years. The data collected was analyzed using statistical tools such as regression analysis and forecasting techniques to accurately assess the current trends.

All the collected data was finally compiled, sorted and presented in the form of reports and graphs. The data was then subjected to in-depth analysis in order to draw a reliable conclusion regarding the market.

Conclusion:

This research project provides a comprehensive analysis of the global Coil Coating market and offers a detailed study of the market dynamics, manufacturers, technology trends and business strategies which will help industry stakeholders such as manufacturers, distributors, retailers etc. to gain deep insights into the industry and develop effective strategies for success.