Global Composite Preform Market Overview

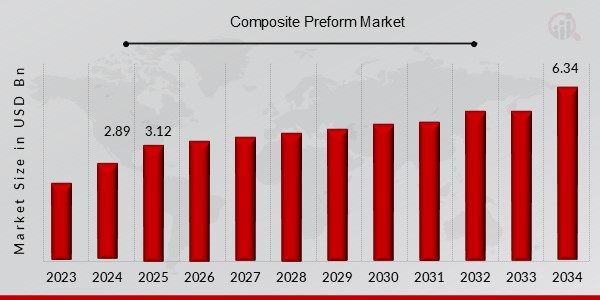

The Composite Preform Market Size was estimated at 2.89 (USD Billion) in 2024. Composite Preform Industry is expected to grow from 3.12 (USD Billion) in 2025 to 6.34 (USD Billion) by 2034, at a CAGR (growth rate) is expected to be around 8.20% during the forecast period (2025 - 2034)

Key Composite Preform Market Trends Highlighted

The Composite Preform Market is experiencing significant developments driven by a growing demand for lightweight materials in various industries, including aerospace, automotive, and construction. The rise in fuel efficiency regulations and sustainability goals pushes manufacturers to seek advanced materials that offer strength and durability without compromising performance. Moreover, technological advancements in manufacturing processes enhance the efficiency and effectiveness of composite preforms, making them more appealing to end-users.

The increasing preference for composite materials over traditional options is also influenced by their versatility and ability to be tailored for specific applications, driving the market forward.There are several opportunities within this market that can be explored further. The growing interest in electric vehicles presents a substantial potential for composite preforms, as these vehicles require lighter materials to improve performance and increase battery efficiency. Emerging economies are also looking to enhance their infrastructure with lightweight materials, creating a new customer base for composite products.

Research and development can open up new applications, especially in niche markets like sports equipment and healthcare products. Continuous innovation and collaboration with end-users can help companies adapt to evolving market needs and capture more significant market shares.In recent times, the focus has shifted toward sustainable practices, which has led to increased investment in bio-based composite materials. Companies are exploring recyclable and eco-friendly options, indicating a trend toward environmental consciousness in manufacturing. This shift aligns with efforts to reduce carbon footprints and promote recycling, leading to a more sustainable future.

Additionally, the integration of smart technologies in manufacturing processes is gaining traction, enabling better quality control and efficiency. The emphasis on research and technological advancements indicates a trend toward more sophisticated applications of composite preforms across various sectors.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Composite Preform Market Drivers

Increasing Demand for Lightweight Materials

One of the most prominent drivers shaping the Composite Preform Market Industry is the rising demand for lightweight materials across various industries. As sectors such as automotive, aerospace, and construction strive for enhanced fuel efficiency and improved performance, the trend towards lightweight materials has gained significant traction. Composite preforms are ideal solutions, offering a combination of high strength-to-weight ratios that traditional materials cannot match.In the automotive industry, for instance, manufacturers are under pressure to reduce vehicle weight to comply with stringent emissions regulations while maintaining safety standards.

Similarly, the aerospace sector is constantly innovating to push the boundaries of travel efficiency, and composite materials play a vital role in designing lighter aircraft components that can withstand extreme conditions. This overarching need for lightweight solutions not only enhances performance and durability but also supports a transition toward sustainability, which is increasingly crucial in today's market environment.The growth in electric vehicles (EVs), powered by the demand for lower energy consumption and environmental considerations, further accelerates the requirement for such advanced materials.

The Composite Preform Market Industry stands to benefit greatly as manufacturers focus on integrating composite preforms into their production processes, ensuring high-quality outputs that resonate with consumer demands for efficiency and eco-friendliness.

Technological Advancements in Manufacturing Processes

Technological advancements in the manufacturing processes for composite materials are significantly driving the Composite Preform Market Industry. Innovations such as automated production techniques, improved resin systems, and enhanced curing processes have made the fabrication of composite preforms more efficient and economical. These advancements enable manufacturers to achieve higher production rates while reducing waste, thus streamlining operations.Additionally, the introduction of cutting-edge technologies is paving the way for the development of high-performance composite materials that cater to specific industry needs, further widening the scope for market expansion.

Growing Investment in Aerospace and Defense Sector

The increasing investment in the aerospace and defense sector is another key driver propelling the Composite Preform Market Industry. With governments and private companies focusing on enhancing their defense capabilities and advancing aerospace technologies, the demand for strong and lightweight materials is surging. Composite preforms are integral to manufacturing components that meet the rigorous standards required in these sectors. This growth trajectory not only boosts demand for composite preforms but also fosters innovation in material development, thus solidifying their role in modern aerospace applications.

Composite Preform Market Segment Insights

Composite Preform Market Application Insights

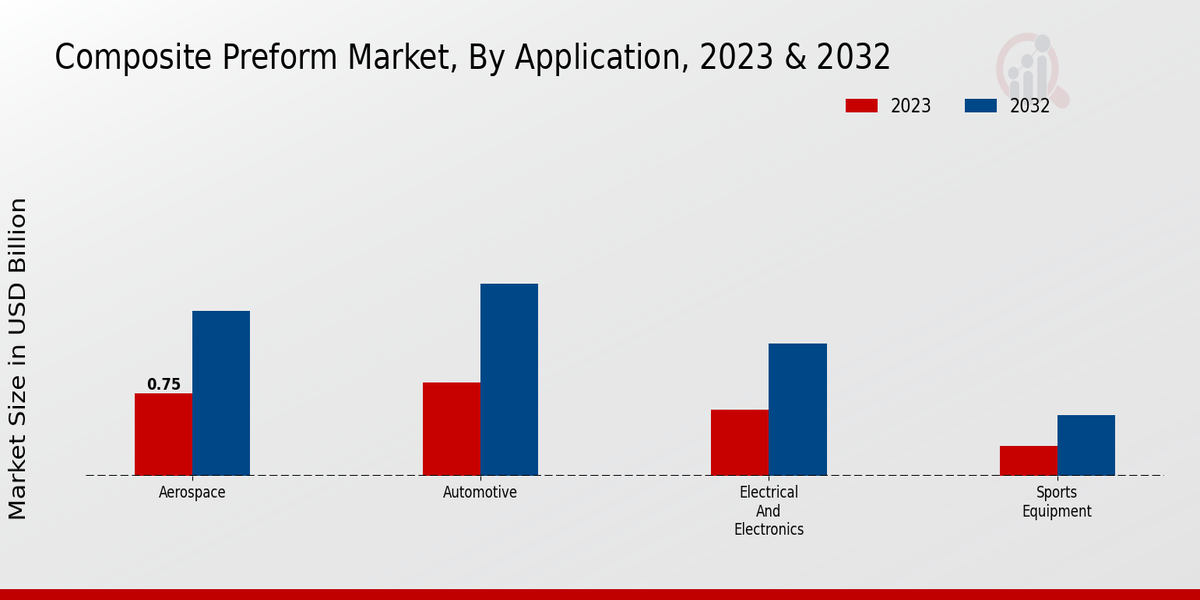

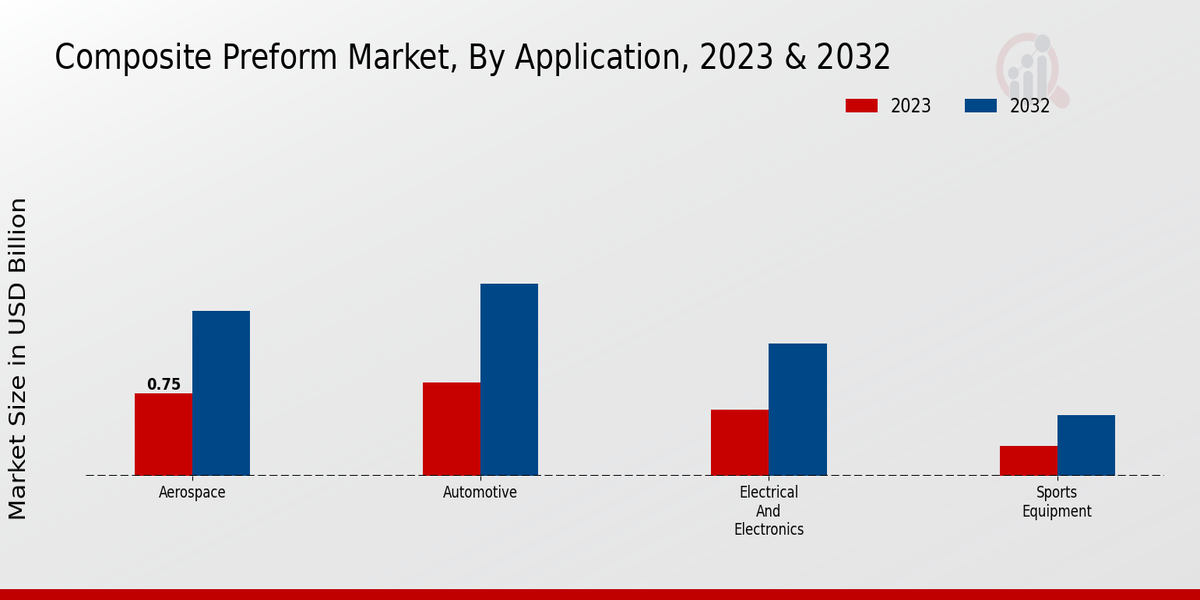

The Composite Preform Market is poised for significant growth, particularly when analyzing the Application segment, which encompasses critical areas such as Aerospace, Automotive, Electrical and Electronics, and Sports Equipment. In 2023, the Aerospace application held a value of 0.75 USD Billion, projected to double to 1.5 USD Billion by 2032. This segment is vital due to the demand for lightweight yet strong materials in aircraft manufacturing, enhancing fuel efficiency and performance. The Automotive sector is slightly larger, starting at 0.85 USD Billion in 2023 and is anticipated to grow to 1.75 USD Billion in 2032.

The need for higher-performance vehicles and increasing fuel economy regulations contribute to the dominance of this segment, making it a key driver in the composite preform market growth.

Electrical and Electronics applications account for a valuation of 0.6 USD Billion in 2023, which is likely to reach 1.2 USD Billion by 2032. This growth is fueled by the demand for lightweight composites that offer superior electrical insulation and reduce overall product weight. Meanwhile, the Sports Equipment sector, while the smallest with a value of 0.27 USD Billion in 2023, expected to reach 0.55 USD Billion in 2032, is crucial for innovations in performance sports gear, highlighting the continual demand for advanced composite materials in high-performance applications.

The Composite Preform Market segmentation reveals that the Aerospace and Automotive industries dominate, collectively representing the majority holding of the overall market, as their applications are essential for achieving improvements in performance and efficiency. Conversely, the Sports Equipment segment, despite being less dominant, showcases significant growth potential and innovation opportunities as the sports and fitness industry continues to evolve. These applications underscore the versatility and necessity of composite preform materials across multiple industries, driving market growth and advancements in technology.

Overall, the market landscape offers numerous opportunities, interconnected with trends ranging from increased efficiency in manufacturing processes to a heightened focus on sustainability in design and material selection. Integrating advanced composite materials into these applications presents both challenges and opportunities for businesses aimed at developing innovative solutions tailored to meet evolving market demands. The Composite Preform Market statistics underscore the importance of these applications and their respective growth trajectories, shaping the industry's future.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Composite Preform Market Material Type Insights

The Composite Preform Market, valued at 2.47 USD Billion in 2023, showcases significant potential for growth, particularly within its Material Type segment. The diverse categories of carbon fiber, glass fiber, natural fiber, and aramid fiber play critical roles in shaping the overall market landscape. Carbon fiber is known for its high strength-to-weight ratio and rigidity, making it a preferred choice in aerospace and automotive industries, thus contributing significantly to market growth.

Glass fiber offers excellent electrical insulation and cost-effectiveness, making it a popular option in construction and manufacturing applications.Meanwhile, natural fiber is gaining traction due to its eco-friendly attributes and sustainable approach, which aligns with trends toward greener materials. Aramid fiber, known for its exceptional heat resistance and durability, also finds its place in safety and protective gear. The demand for these materials reflects rising trends in lightweight construction and increased performance efficiency across various industries, aligning with overall prospects for the Composite Preform Market revenue.

Composite Preform Market Manufacturing Process Insights

The Composite Preform Market, particularly within the Manufacturing Process segment, plays a vital role in the overall growth of the industry. In 2023, the market was noted to be valued at 2.47 billion USD, with projections for the future indicating a strong upward trend. Compression molding is a prevalent technique due to its efficiency and ability to produce complex shapes, making it significant in industries where precision is key.

Injection molding thrives in high-volume production settings, appealing to businesses that require rapid manufacturing of components.Thermoforming, known for its versatility, is crucial in applications ranging from packaging to automotive parts, providing manufacturers with numerous design options. Lastly, pultrusion is essential in producing continuous lengths of composite materials, particularly for construction and infrastructure. The Composite Preform Market revenue is driven by these diverse processes, catering to various sectors while addressing evolving consumer preferences and sustainability aspects.

As noted in Composite Preform Market data, these manufacturing methods are important for meeting the increasing demand for lightweight, durable products.Overall, the sector is experiencing notable market growth, presenting opportunities for advancements and innovations in composite material applications.

Composite Preform Market End Use Industry Insights

The Composite Preform Market has observed a notable trajectory, with a valuation of 2.47 billion USD in 2023 and projected growth to 5.0 billion USD by 2032. Within the End Use Industry segment, various domains such as Transportation, Construction, Consumer Goods, and Industrial Equipment contribute significantly to the market dynamics.

The Transportation sector, known for its demand for lightweight, strong materials, plays a critical role in driving the need for composite preforms, enhancing fuel efficiency while adhering to safety standards.Similarly, the Construction industry increasingly adopts these materials due to their durability and resistance to environmental factors, making them suitable for structural applications. Consumer Goods also significantly impact market growth as manufacturers seek to innovate and improve product performance through the integration of composite materials.

In the realm of Industrial Equipment, the focus on high-performance and lightweight components further underscores the segment's importance within the overall Composite Preform Market revenue framework.Together, these segments form a comprehensive landscape that showcases the diverse applications and potential growth opportunities inherent in the market.

Composite Preform Market Regional Insights

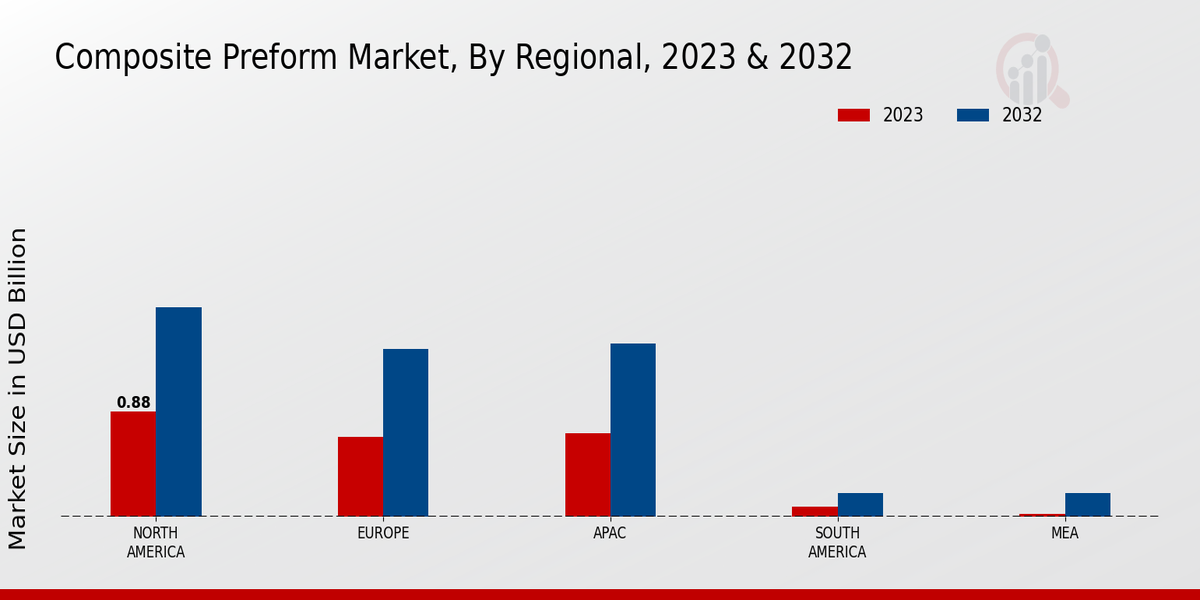

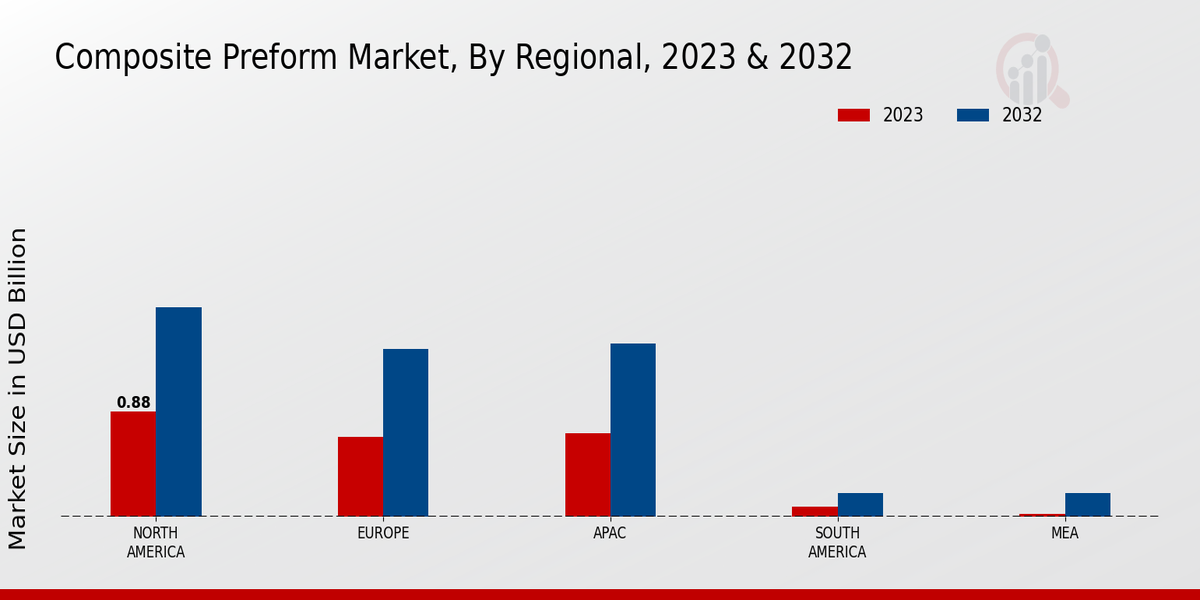

The Composite Preform Market is witnessing substantial growth across various regions, with a total market valuation of 2.47 USD Billion in 2023. North America stands out with a significant valuation of 0.88 USD Billion in 2023, projected to reach 1.75 USD Billion by 2032, indicating its dominant position in the market. Europe follows closely, valued at 0.67 USD Billion in 2023 and expected to grow to 1.4 USD Billion, driven by advancements in manufacturing technologies and increasing adoption in aerospace applications.

The Asia-Pacific (APAC) region, with a valuation of 0.7 USD Billion in 2023, is anticipated to grow to 1.45 USD Billion, showcasing its emerging importance due to rising industrialization and demand in automotive sectors.South America and the MEA region, while smaller in comparison, are valued at 0.09 USD Billion and 0.03 USD Billion, respectively, in 2023, with projections of growth to 0.2 USD Billion by 2032 each. The challenges of lower market penetration in these regions present opportunities for growth, driven by increasing emphasis on composite materials for lightweight and durable applications.

Overall, the Composite Preform Market segmentation highlights regional dynamics and showcases North America's majority holding as a key player.

Source: Primary Research, Secondary Research, Market Research Future Database and Analyst Review

Composite Preform Market Key Players and Competitive Insights

The Composite Preform Market is characterized by a dynamic competitive environment, driven largely by the rising demand for lightweight and durable materials across various end-use sectors, such as aerospace, automotive, and construction. This market encompasses a wide range of applications where composite preforms are utilized, emphasizing advancements in manufacturing technologies and material compositions. As companies vie for market share, innovations in product development and strategic partnerships have become crucial strategies, enabling businesses to enhance their offerings. The competitive landscape is further shaped by the need for sustainability and environmental considerations, prompting companies to explore eco-friendlier composite solutions.

Analyzing market trends and competitor strategies provides insights into how players in the market are positioning themselves to capture growth opportunities and address the evolving needs of their customers.Hexcel stands out in the Composite Preform Market with a robust presence rooted in innovation and extensive expertise in aerospace and industrial applications. The company's strengths lie in its advanced material technologies, particularly in the development of high-performance composites, which are crucial for manufacturers seeking to improve efficiency and reduce weight in various applications.

Hexcel has cultivated strong relationships within the aerospace sector, offering an impressive portfolio that provides customers with tailored solutions. Its commitment to research and development helps Hexcel maintain a competitive edge in creating cutting-edge products that meet the stringent performance and regulatory requirements of the industry. Furthermore, the company's strategic approach to expanding production capabilities ensures it stays ahead in a challenging market landscape.Teijin Limited also holds a significant position in the Composite Preform Market, known for its diverse range of innovative material solutions.

The company distinguishes itself through its focus on engineering-oriented products tailored for a variety of industrial applications, particularly in the automotive sector, where lightweight solutions are increasingly critical. Teijin Limited’s investment in developing composite technologies has bolstered its reputation as a leader in sustainability, with an emphasis on reducing environmental impact while enhancing product performance. This focus on environmentally responsible practices has positioned the company favorably among consumers and industries looking for eco-friendly options.

Teijin Limited's expertise in research and development enables the company to innovate continuously, providing new composite preform solutions that meet the evolving demands of the market while working to expand its reach and customer base.

Key Companies in the Composite Preform Market Include

- Aerospace Composite Products

Composite Preform Industry Developments

-

Q2 2024: Hexcel Opens New Carbon Fiber Preform Manufacturing Facility in Morocco Hexcel Corporation inaugurated a new manufacturing facility in Casablanca, Morocco, dedicated to producing advanced carbon fiber preforms for aerospace applications. The plant aims to support growing demand from Airbus and other European aerospace customers.

-

Q1 2024: Teijin Launches Next-Generation Composite Preform for Automotive Lightweighting Teijin Limited announced the commercial launch of a new composite preform technology designed to enable faster, more cost-effective production of lightweight automotive components, targeting electric vehicle manufacturers.

-

Q2 2024: Toray Industries and Boeing Expand Partnership for Advanced Composite Preforms Toray Industries signed a multi-year agreement with Boeing to supply advanced composite preforms for use in next-generation commercial aircraft, strengthening their long-standing materials partnership.

-

Q3 2024: Spirit AeroSystems Secures Major Contract for Composite Preform Structures from Airbus Spirit AeroSystems announced a new contract with Airbus to supply large-scale composite preform structures for the A320neo family, expanding its role in the European aerospace supply chain.

-

Q2 2024: SGL Carbon Invests in New Preform Production Line in Germany SGL Carbon revealed an investment in a new automated preform production line at its Meitingen site, aimed at increasing capacity for automotive and wind energy customers.

-

Q1 2024: Saertex Launches 3D Glass Fiber Preform for Wind Turbine Blades Saertex introduced a new 3D glass fiber preform product specifically engineered for next-generation wind turbine blades, offering improved strength and reduced manufacturing cycle times.

-

Q2 2024: Owens Corning Announces Strategic Partnership with Siemens Gamesa for Composite Preforms Owens Corning entered a strategic partnership with Siemens Gamesa to develop and supply composite preforms for offshore wind turbine applications, focusing on sustainability and performance.

-

Q3 2024: A&P Technology Expands Braided Preform Capacity with New U.S. Facility A&P Technology opened a new manufacturing facility in Ohio to expand its braided composite preform production, targeting aerospace and defense markets.

-

Q1 2025: GKN Aerospace Wins Contract to Supply Composite Preforms for Urban Air Mobility Vehicles GKN Aerospace secured a contract to design and manufacture composite preforms for a leading urban air mobility (UAM) startup, supporting the development of next-generation electric vertical takeoff and landing (eVTOL) aircraft.

-

Q2 2025: Mitsubishi Chemical Acquires Stake in European Composite Preform Startup Mitsubishi Chemical announced the acquisition of a minority stake in a European startup specializing in automated composite preform manufacturing, aiming to accelerate innovation in lightweight materials.

-

Q2 2024: BMW Group Opens New Composite Preform Center for Electric Vehicle Production BMW Group inaugurated a new composite preform center in Germany to support the production of lightweight structural components for its next-generation electric vehicles.

-

Q3 2024: Airbus Launches In-House Composite Preform R&D Program Airbus announced the launch of an in-house research and development program focused on advanced composite preform technologies, aiming to reduce costs and improve sustainability in future aircraft production.

Composite Preform Market Segmentation Insights

Composite Preform Market Application Outlook

- Electrical and Electronics

Composite Preform Market Material Type Outlook

Composite Preform Market Manufacturing Process Outlook

Composite Preform Market End Use Industry Outlook

Composite Preform Market Regional Outlook

|

Report Attribute/Metric

|

Details

|

|

Market Size 2024

|

2.89 (USD Billion)

|

|

Market Size 2025

|

3.12 (USD Billion)

|

|

Market Size 2034

|

6.34 (USD Billion)

|

|

Compound Annual Growth Rate (CAGR)

|

8.20% (2025 - 2034)

|

|

Report Coverage

|

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends

|

|

Base Year

|

2024

|

|

Market Forecast Period

|

2025 - 2034

|

|

Historical Data

|

2020 - 2024

|

| Market Forecast Units |

USD Billion |

| Key Companies Profiled |

Hexcel, Teijin Limited, Aerospace Composite Products, BASF, Cytec Solvay Group, SGL Carbon, 3M, Ahrens Engineering, Hexion, Zoltek, Advanced Composite Group, Toray Industries, Gurit, Formosa Plastics, Mitsubishi Chemical |

| Segments Covered |

Application, Material Type, Manufacturing Process, End Use Industry, Regional |

| Key Market Opportunities |

Sustainable materials demand growth, Increasing aerospace applications, Automotive lightweighting initiatives, Enhanced manufacturing technologies, and Expanding wind energy sector. |

| Key Market Dynamics |

rising demand for lightweight materials, increasing automotive and aerospace applications, advancements in composite manufacturing technologies, environmental sustainability initiatives, growing investments in R |

| Countries Covered |

North America, Europe, APAC, South America, MEA |

Frequently Asked Questions (FAQ):

The Composite Preform Market is expected to be valued at 6.34 USD Billion by 2034.

In 2024, the Composite Preform Market was valued at 2.89 USD Billion.

The expected CAGR for the Composite Preform Market from 2025 to 2034 is 8.20%.

The Aerospace application segment is projected to grow to 1.5 USD Billion by 2032.

The Automotive application segment is projected to reach a market size of 1.75 USD Billion by 2032.

North America is valued at 0.88 USD Billion in 2023 and is expected to reach 1.75 USD Billion by 2032.

By 2032, the market size for the Europe region is expected to be 1.4 USD Billion.

Major players in the market include Hexcel, Teijin Limited, and Toray Industries among others.

The market value for the Electrical and Electronics application is 0.6 USD Billion in 2023.

The Sports Equipment application segment is expected to be valued at 0.55 USD Billion by 2032.