- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

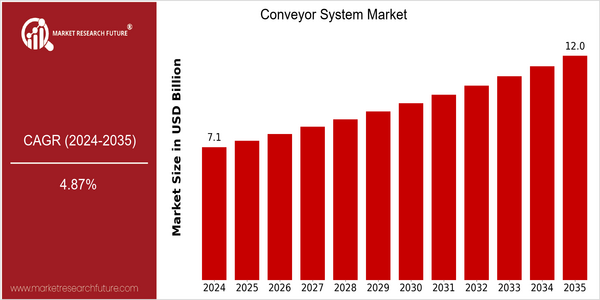

Conveyor System Market Size Snapshot

| Year | Value |

|---|---|

| 2024 | USD 7.11 Billion |

| 2035 | USD 12.0 Billion |

| CAGR (2025-2035) | 4.87 % |

Note – Market size depicts the revenue generated over the financial year

In the foreseeable future, the global conveyor belts market will grow at a CAGR of 8.6% from 2024 to 2035. This means that the demand for conveyor belts will continue to grow steadily across various industries. The need for automation in the manufacturing and logistics industries, combined with the rise of e-commerce, will drive this growth. The need to improve efficiency and reduce labor costs will force companies to adopt advanced conveyor technology. There are several factors that will drive the conveyor belt market. Firstly, the integration of IoT and AI in conveyor belts will increase their functionality and efficiency. Also, the push for sustainable development will result in the development of energy-efficient conveyor belts. The leading companies in the market, such as Honeywell, Daifuku, and Siemens, are investing heavily in research and development to stay ahead of the competition. These companies are also forming strategic alliances and acquiring smaller companies to increase their market share and improve their technological capabilities.

Regional Deep Dive

The conveyor system market is experiencing considerable growth in all regions, driven by automation in manufacturing and logistics, and the rising demand for efficient material handling solutions. North America is characterised by the advanced adoption of technology and a strong focus on the environment, while Europe is characterized by a high level of regulatory compliance and innovation. Asia-Pacific is experiencing rapid industrialization and urbanization, which is resulting in a strong demand for conveyor systems. The Middle East and Africa (MEA) region is characterised by a strong focus on logistics and transport, while Latin America is gradually adopting automation technology to increase productivity.

North America

- In the same way, as e-commerce has increased, so has investment in conveyor systems, as Amazon and Walmart have expanded their distribution centers to improve logistics.

- The regulations on safety and the environment, the increasing demands for energy conservation, are forcing manufacturers to adopt more advanced conveyor systems.

- IT companies such as Siemens and Honeywell are developing smart conveyor systems which use the Internet of Things to enhance their monitoring and maintenance capabilities.

Europe

- The European Green Deal is promoting the development of sustainable conveyors. The companies are working on reducing their carbon footprint by designing energy-efficient systems.

- In the field of automation, new developments in the field of transport and conveyor systems are gaining ground, which enable the manufacturing industry to become more flexible and individual. Companies like Bosch Rexroth are in the vanguard of this development.

- Regulations in Europe are increasingly oriented towards automation and digitalization, which leads to investments in intelligent conveyor solutions that increase productivity and safety.

Asia-Pacific

- In the last decade, the rapid industrialization of countries such as China and India has created a great demand for conveyor belts, especially in the manufacture of automobiles and electrical appliances.

- The development of smart factories and the introduction of Industry 4.0 have led to the integration of the latest technology in the conveyor systems, with Mitsubishi Electric at the forefront of these developments.

- The Make in India initiative, which is aimed at promoting the manufacturing industry, has led to the investment in conveyors and other equipment.

MEA

- The significant investments in logistics and transport infrastructure projects, such as the Dubai Logistic City, are driving the demand for advanced conveyor systems in the region.

- This is the case in the mining and oil industries, where the automation of processes is leading to a growing use of conveyor systems, where companies such as FLSmidth are able to provide tailor-made solutions.

- Industry is constantly changing and modernizing, following new requirements for safety and productivity.

Latin America

- In the sphere of manufacturing, the shift to automation is gradually taking place. To increase productivity and reduce costs, companies are investing in automation.

- Brazil and Mexico are particularly receptive to the modern conveyor systems.

- The growth of the warehousing industry in the main cities of the country has created a demand for more efficient material handling systems, and both local and international companies have joined forces to meet this demand.

Did You Know?

“Some seventy per cent of all manufacturing and distributive establishments use some form of conveyor to improve the performance of their operations.” — Material Handling Industry of America (MHIA)

Segmental Market Size

The conveyor system market is growing steadily, driven by the automation of the manufacturing industry. The rising importance of e-commerce and the growing need for fast and reliable logistics are two of the main drivers of this market. In addition, the increasing demand for safety and efficiency in the workplace is also promoting the use of conveyor systems in the production and distribution industries.

At the present time, the market is in a state of advanced development, and the leaders are putting into operation the most advanced conveyors. The most important branches of application are the warehousing, automobile, and food industries. In these industries, the conveyors make the work easier and reduce labor costs. The trend towards smart factories and sustainable development is increasing the market, because companies are aiming to reduce their waste and increase their efficiency. The development of the Internet of Things and artificial intelligence is changing the conveyors. It enables them to monitor and control their performance in real time.

Future Outlook

The conveyor belts market is expected to grow at a CAGR of 4.87% from 2024 to 2035. The growing demand for automation in the manufacturing, transport, and food industries is expected to propel the market growth. The companies are increasingly adopting advanced conveyor systems in order to increase the productivity and reduce the cost of labor. Hence, the penetration of the advanced conveyor systems in the above-mentioned industries is expected to increase, and the share of the advanced conveyor belts in the automated factories is expected to reach more than 60% by 2035.

The main technological drivers are the integration of IoT (Internet of Things) and AI (Artificial Intelligence) into conveyor systems. These enable real-time monitoring, preventive maintenance and a greater degree of operational flexibility, all of which are necessary to meet the evolving requirements of supply chain management. Moreover, as a result of the global drive towards greater energy efficiency and the growing focus on reducing carbon footprints, the development of energy-efficient conveyor systems will be a further growth driver. Moreover, the emergence of smart factories and the growing importance of e-commerce will also play an important role in the future development of the conveyor systems market.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2023 | USD 8.0 Billion |

| Growth Rate | 3.41% (2024-2032) |

Conveyor System Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.