Top Industry Leaders in the Cutting Equipment Market

*Disclaimer: List of key companies in no particular order

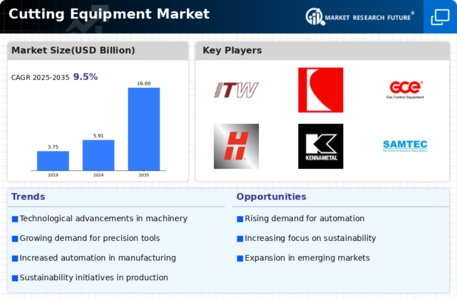

Top listed global companies in the industry are:

- Illinois Tool Works

- AMADA WELD TECH

- The Lincoln Electric Company

- Colfax Corporation

- Koike Aronson, Inc.

- GCE Group

- Ador Welding Ltd.

- OMAX Corporation

- Hypertherm, Inc.

- Jet Edge, Inc.

- DAIHEN Corporation

- V Mineral

- OTTO BAIER GmbH

- ICS Cutting Tools, Inc.

- Snap-on Incorporated

- CERATIZIT S.A.

- Opta Group LLC.

- WB Alloys Welding Products Ltd

- Kennametal Inc.

- Samtectools

- HOLLFELDER-GÜHRING GmbH and others

Sharpening the Edge: Navigating the Competitive Landscape of Cutting Equipment

The cutting equipment market is a diverse, dynamic, and often unforgiving realm where precision meets power. From delicate dental drills to heavy-duty industrial saws, these tools carve, slice, and sever their way through countless materials, shaping our world one cut at a time. But beyond the whirring blades and flying sparks lies a competitive landscape as intricate as the cuts themselves. Let's delve into this market, examining key player strategies, market share determinants, emerging trends, and the overall battle for cutting supremacy.

Dominant Players and Their Strategies:

- Bosch Group: This German industrial giant wields a vast portfolio of cutting tools, catering to diverse industries with power tools, drills, saws, and laser cutters. Their focus on technological innovation, ergonomic design, and safety features helps them maintain a global lead.

- Stanley Black & Decker: This American behemoth challenges Bosch with a broad range of power tools and blades, targeting both professional and DIY users. Their focus on brand recognition, affordability, and extensive distribution networks fuels their market share.

- Makita Corporation: This Japanese powerhouse emphasizes quality and durability in its professional-grade cutting tools. Their focus on cordless technology, dust suppression systems, and user-friendly features attracts skilled tradespeople and construction professionals.

- Festool AG: This German specialist carves a niche with high-precision, dust-free cutting solutions for woodworking and fine carpentry. Their focus on advanced technologies, modular systems, and customizability attracts woodworking enthusiasts and professional craftspeople.

Factors Dictating Market Share:

- Product Portfolio Breadth and Depth: Offering diverse cutting tools for various applications, materials, and user segments expands market reach and attracts a wider customer base.

- Quality and Durability: Ensuring consistent performance, long lifespan, and minimal breakdown is crucial for building trust and customer loyalty in a demanding market.

- Technological Innovation: Integrating advanced features like cordless technology, laser guidance, and smart tool connectivity provides a competitive edge.

- Brand Recognition and Reputation: Established brands with a strong reputation for quality and reliability naturally attract more customers.

- Price and Value Proposition: Balancing affordability with performance and features is crucial for capturing different customer segments, from professional users to DIY enthusiasts.

New and Emerging Trends:

- Focus on Automation and Robotics: Integration of robotic arms and automated cutting systems in industrial applications improves efficiency, safety, and precision.

- Development of Smart Cutting Tools: Tools with built-in sensors, feedback systems, and data analytics capabilities optimize performance and minimize material waste.

- Sustainability and Environmentally Friendly Materials: Manufacturers are developing energy-efficient cutting tools and using recycled materials to cater to eco-conscious consumers.

- Focus on Customization and Modular Systems: Allowing users to configure cutting tools with specific blades, accessories, and attachments caters to individual needs and fosters market flexibility.

Overall Competitive Scenario:

The cutting equipment market is a battleground where established giants wrestle with innovative startups, all vying for a slice of the pie. Technology is shaping the future, with automation, smart tools, and data-driven solutions becoming crucial differentiators. Sustainability is also emerging as a key factor, pushing manufacturers to develop eco-friendly tools and minimize waste. While price sensitivity remains a concern, the market is increasingly valuing quality, durability, and user-centric features.

In conclusion, navigating the competitive landscape of the cutting equipment market requires a keen understanding of key players, market share determinants, and emerging trends. By offering innovative, reliable, and user-friendly cutting solutions while remaining mindful of affordability and sustainability, companies can sharpen their edge and carve a successful path in this demanding and multifaceted market.

Latest Company Updates:

July 2023

AMADA WELD TECH, a developer of equipment and systems for cutting, welding, marking, sealing, and bonding, has released a line of Galvo scan heads for precision laser welding applications. Galvo scanning heads help precisely direct as well as control the laser beam’s entire movement with the use of galvanometer mirrors (galvos) and then steer the laser beam in any direction with high speed as well as accuracy. These scanning heads are frequently used for beam weaving to increase weld width, multi-point positioning for hermetic seams, and shape welding for hermetic seams.

The Galvo scan heads all have cutting-edge, user-friendly welding software and a programmable pattern to correct for part shape and improve weld performance. Operators are guaranteed a secure working environment thanks to an incorporated safety shutter.

The solutions are made to function with lasers as powerful as 3 kW and with fields as big as 100 × 100 millimetres. To accommodate tolerances in fit-up for seam welds, integrate with a linear stage motion to weld at various workpiece heights, or add a wobble to a linear motion.

March 2023

For the testing standard CSN EN ISO/IEC 17025:2018, GCE Group has been given an accreditation certificate. The five-year certification, obtained by GCE's Research and Development Laboratory in Chotebor, Czech Republic, includes new test procedures and re-accreditation for its prior scope of accreditation.

The GCE Group is a well-known manufacturer in Europe of gas control devices, pressure regulators, valves, and flow meters for oxygen and acetylene welding and cutting apparatus, high-purity gases, and industrial uses in the fields of medicine and electronics.