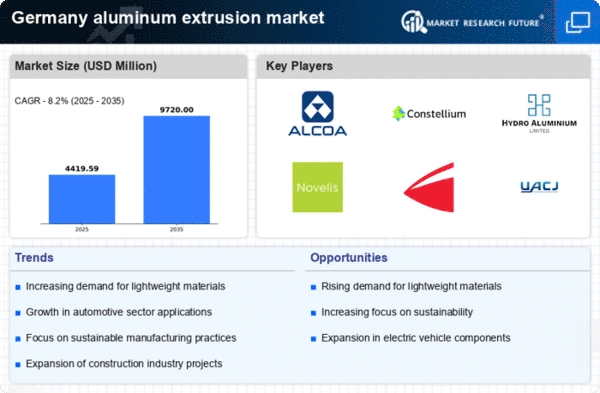

The aluminum extrusion market in Germany is currently experiencing a dynamic phase. This phase is characterized by evolving consumer preferences and technological advancements. The demand for lightweight materials in various sectors, including automotive and construction, is driving innovation in extrusion processes. Manufacturers are increasingly focusing on sustainability, utilizing recycled aluminum to meet environmental standards and consumer expectations. This shift not only enhances the market's appeal but also aligns with broader trends towards eco-friendly practices. Furthermore, advancements in automation and digitalization are streamlining production, improving efficiency, and reducing costs. As a result, companies are better positioned to respond to market fluctuations and customer needs.

In addition, the regulatory landscape in Germany is influencing the aluminum extrusion market. Stricter regulations regarding emissions and energy consumption are prompting manufacturers to adopt cleaner technologies. This regulatory pressure, while challenging, also presents opportunities for growth as companies innovate to comply with new standards. The interplay between sustainability, technology, and regulation is likely to shape the future of the aluminum extrusion market. This will foster a competitive environment that encourages continuous improvement and adaptation. Overall, the market appears poised for growth, driven by a combination of consumer demand, technological progress, and regulatory influences.

Sustainability Initiatives

The aluminum extrusion market is witnessing a notable shift towards sustainability. Manufacturers are increasingly adopting practices that prioritize the use of recycled aluminum, which not only reduces waste but also lowers energy consumption during production. This trend aligns with the growing consumer demand for environmentally friendly products and is supported by government initiatives promoting sustainable manufacturing.

Technological Advancements

Innovations in technology are significantly impacting the aluminum extrusion market. Automation and advanced manufacturing techniques are enhancing production efficiency and precision. These technological improvements enable companies to produce complex profiles and meet diverse customer requirements, thereby expanding their market reach and competitiveness.

Regulatory Compliance

The regulatory environment in Germany is becoming more stringent, particularly concerning emissions and energy efficiency. This trend compels manufacturers in the aluminum extrusion market to invest in cleaner technologies and processes. Compliance with these regulations not only mitigates environmental impact but also positions companies favorably in a market increasingly focused on sustainability.