- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

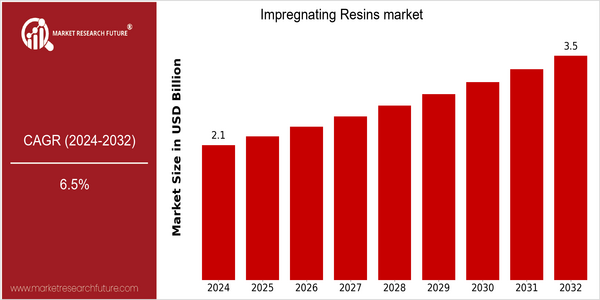

| Year | Value |

|---|---|

| 2024 | USD 2.11 Billion |

| 2032 | USD 3.49 Billion |

| CAGR (2024-2032) | 6.5 % |

Note – Market size depicts the revenue generated over the financial year

Impregnating resins market is expected to grow at a CAGR of 3.49 % over the forecast period, the report says. The growth will be at a CAGR of 6.5% during the forecast period. Increasing demand for impregnating resins in various industries, particularly in the electrical and electronics, automotive, and construction industries, is the key driver of the market. Besides, the trend of focusing on the performance and life of products has increased the demand for impregnating resins. The market is driven by a number of factors. The first is the development of the impregnating resins industry. The second is the development of the formulation of resins to increase the thermal stability and electrical insulating properties of the products. The third is the growing emphasis on energy efficiency and the need to use environment-friendly products. The market is characterized by the presence of many players, such as Hexion Inc., Momentive Performance Materials Inc., and Huntsman Corp., which are mainly involved in strategic alliances and the launch of new products to strengthen their positions in the market and meet the changing needs of customers. The market is characterized by a high degree of competition and a high degree of innovation. These factors will lead to a further increase in the market in the coming years.

Regional Market Size

Regional Deep Dive

The market for impregnating resins is characterized by a broad range of applications in a number of industries, including electrical, automobile and building. In North America, the market is driven by an increasing demand for high-performance materials that improve the life and performance of electrical components. In addition, the region benefits from a strong manufacturing industry and large R&D expenditures that encourage innovation and the development of new resin formulations. Also, the increasing emphasis on sustainable products is influencing the market, resulting in the development of bio-based impregnating resins.

Europe

- The European market is witnessing a shift towards sustainable materials, with companies like BASF and Huntsman Corporation focusing on developing eco-friendly impregnating resins that comply with the EU's stringent environmental regulations.

- The European Union's Green Deal is driving investments in green technologies, which is expected to boost the demand for impregnating resins in renewable energy applications, particularly in wind and solar energy sectors.

Asia Pacific

- Rapid industrialization and urbanization in countries like China and India are propelling the demand for impregnating resins, particularly in the electrical and electronics industries.

- Local manufacturers are increasingly collaborating with global companies to enhance their product offerings, as seen in partnerships between Asian firms and major players like 3M and DuPont to develop advanced resin technologies.

Latin America

- In Latin America, the market is influenced by the growing automotive industry, particularly in Brazil and Mexico, where there is an increasing need for durable and efficient impregnating resins.

- Government initiatives aimed at boosting local manufacturing capabilities are encouraging investments in resin production facilities, which is expected to enhance the availability of high-quality impregnating resins in the region.

North America

- Recent advancements in resin technology have led to the introduction of low-VOC (volatile organic compounds) impregnating resins, which are gaining traction due to stricter environmental regulations in the U.S. and Canada.

- Key players such as Hexion Inc. and Momentive Performance Materials are actively investing in R&D to develop innovative resin solutions that cater to the evolving needs of the electrical and automotive sectors.

Middle East And Africa

- The Middle East is experiencing growth in the impregnating resins market due to the expansion of the construction sector, with significant projects like NEOM in Saudi Arabia driving demand for high-performance materials.

- Regulatory changes aimed at improving product quality and safety standards in the region are encouraging manufacturers to adopt advanced resin technologies, thereby enhancing market competitiveness.

Did You Know?

“Did you know that impregnating resins can significantly improve the thermal and electrical insulation properties of electrical components, making them essential for high-performance applications?” — Market research studies and industry reports

Segmental Market Size

Impregnating resins are used to improve the strength and performance of electrical insulating materials, especially in the manufacture of motors, transformers, and other electrical components. This market is currently growing steadily, driven by the increasing demand for energy-efficient electrical appliances and improvements in the formulations of the resins. Also boosting demand are the growing requirements of the automobile and aeronautical industries for electrical insulating materials with higher performance characteristics, and the implementation of stricter regulations aimed at reducing energy consumption and emissions. The market penetration of impregnating resins is now in the process of being scaled up, with Hexion and Huntsman as the pioneers in this field. The most important use of these products is in the motors of electric vehicles and in the generation of energy from renewable sources, where improved thermal stability and electrical resistance are critical. The global trend towards greater energy efficiency and the transition to electric mobility are also accelerating the growth of this market. The further development of resins, with the development of low-VOC and bio-based formulations, is shaping the future of impregnating resins, in line with the growing demand for sustainable solutions.

Future Outlook

The market for impregnating resins will grow significantly from 2024 to 2032. Its value will rise from $2.11 billion to $3.49 billion, a strong CAGR of 6.5%. In addition to the increasing demand for high-performance materials from various industries, such as the automobile, the electrical and the wind energy industries, the resin market will benefit from the development of new products and the improvement of existing products. , the application of the resins will increase in applications such as electrical components and electrical insulation, which will lead to an increase in penetration. The main technological developments, especially in the formulation and curing of the resins, are expected to drive the development of the industry. The development of low-VOC and environmentally friendly resins, in line with global trends and regulations, is gaining momentum. The integration of smart technology into the manufacturing process will also help to improve the performance of impregnating resins, making them more attractive to end users. These trends will lead to a shift towards more specialized and application-oriented resins to meet the needs of different industries.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 6.6% (2023-2030) |

Impregnating Resins Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.