- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

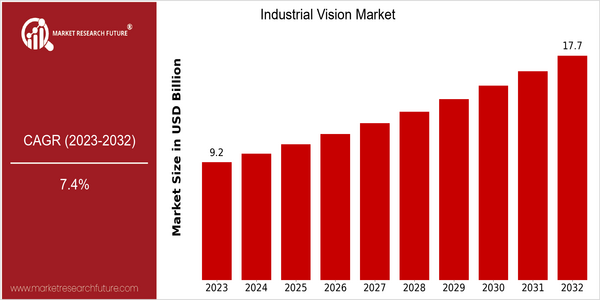

| Year | Value |

|---|---|

| 2023 | USD 9.22 Billion |

| 2032 | USD 17.71 Billion |

| CAGR (2024-2032) | 7.4 % |

Note – Market size depicts the revenue generated over the financial year

The global Industrial Vision Market is currently valued at USD 9.22 billion in 2023 and is projected to reach USD 17.71 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 7.4% from 2024 to 2032. This growth trajectory indicates a strong demand for advanced vision systems across various industries, driven by the increasing need for automation, quality control, and enhanced operational efficiency. As manufacturers seek to optimize production processes and reduce errors, the adoption of industrial vision technologies is becoming increasingly critical. Several factors are propelling this market expansion, including advancements in artificial intelligence (AI) and machine learning, which are enhancing the capabilities of vision systems. The integration of these technologies allows for more sophisticated image processing and analysis, enabling real-time decision-making and improved accuracy in inspections. Additionally, the rise of Industry 4.0 and the Internet of Things (IoT) is fostering a more interconnected manufacturing environment, further driving the demand for industrial vision solutions. Key players in this market, such as Cognex Corporation, Keyence Corporation, and Siemens AG, are actively investing in research and development, forming strategic partnerships, and launching innovative products to capitalize on these trends and meet the evolving needs of their customers.

Regional Market Size

Regional Deep Dive

The Industrial Vision Market is experiencing significant growth across various regions, driven by advancements in automation, artificial intelligence, and machine learning technologies. In North America, the market is characterized by a strong presence of key players and a high adoption rate of innovative solutions in manufacturing and quality control processes. Europe showcases a robust regulatory framework that encourages the integration of vision systems in industrial applications, while Asia-Pacific is rapidly emerging as a hub for technological innovation and manufacturing expansion. The Middle East and Africa are witnessing increased investments in industrial automation, and Latin America is gradually adopting vision systems to enhance operational efficiency.

Europe

- The European Union's Industry 4.0 initiative is fostering innovation in the industrial vision market, encouraging manufacturers to adopt smart technologies that enhance productivity and efficiency.

- Companies like Siemens and Bosch are investing heavily in R&D for vision systems, focusing on applications in smart factories and predictive maintenance, which are reshaping the manufacturing landscape.

Asia Pacific

- China's 'Made in China 2025' initiative is propelling the adoption of industrial vision systems, with local firms like Hikvision and Dahua Technology developing cutting-edge solutions tailored for various industries.

- The region is witnessing a surge in demand for vision systems in electronics manufacturing, driven by the increasing complexity of products and the need for stringent quality control measures.

Latin America

- Brazil is emerging as a key player in the industrial vision market, with government programs aimed at modernizing manufacturing processes and increasing competitiveness in global markets.

- Local companies are increasingly adopting vision systems to improve quality control in food and beverage production, driven by rising consumer demand for safety and quality.

North America

- The integration of AI and machine learning in industrial vision systems is gaining traction, with companies like Cognex and Keyence leading the charge in developing advanced solutions for quality inspection and process automation.

- Regulatory initiatives, such as the U.S. Department of Labor's focus on enhancing workplace safety through automation, are driving demand for industrial vision technologies, particularly in sectors like automotive and pharmaceuticals.

Middle East And Africa

- The UAE's Vision 2021 initiative is promoting the adoption of advanced technologies, including industrial vision systems, to enhance the efficiency of manufacturing and logistics sectors.

- Investment in smart manufacturing technologies is on the rise, with companies like Schneider Electric and local startups collaborating to develop innovative vision solutions tailored to regional needs.

Did You Know?

“Approximately 70% of manufacturers in North America are expected to implement some form of industrial vision technology by 2025, significantly enhancing their operational efficiency.” — Industry reports from the Association for Advancing Automation (A3)

Segmental Market Size

The Industrial Vision Market segment is currently experiencing robust growth, driven by increasing automation and the need for enhanced quality control in manufacturing processes. Key factors propelling demand include the rising adoption of Industry 4.0 practices and the growing emphasis on operational efficiency. Companies are increasingly integrating vision systems to streamline production lines and reduce human error, which is critical in sectors like automotive and electronics manufacturing. Currently, the adoption stage of industrial vision systems is transitioning from pilot phases to scaled deployment, with notable leaders such as Siemens and Cognex spearheading initiatives in Europe and North America. Primary applications include quality inspection, robotic guidance, and measurement systems, particularly in automotive assembly lines and semiconductor fabrication. Macro trends such as the push for sustainability and the impact of the COVID-19 pandemic are accelerating the shift towards automated solutions. Technologies like artificial intelligence and machine learning are shaping the evolution of this segment, enabling more sophisticated image processing and analysis capabilities.

Future Outlook

The Industrial Vision Market is poised for significant growth from 2023 to 2032, with a projected market value increase from $9.22 billion to $17.71 billion, reflecting a robust compound annual growth rate (CAGR) of 7.4%. This growth trajectory is driven by the increasing adoption of automation and advanced manufacturing technologies across various industries, including automotive, electronics, and pharmaceuticals. As companies strive for enhanced operational efficiency and quality control, the integration of vision systems for inspection, guidance, and measurement is becoming indispensable. By 2032, it is anticipated that the penetration of industrial vision systems will reach approximately 30% of manufacturing processes, up from around 15% in 2023, indicating a substantial shift towards automated visual inspection solutions. Key technological advancements, such as the development of artificial intelligence (AI) and machine learning algorithms, are expected to further propel the market. These technologies enhance the capabilities of vision systems, enabling real-time data analysis and decision-making, which are critical for maintaining competitive advantage in fast-paced industrial environments. Additionally, the growing emphasis on Industry 4.0 and smart factories is likely to drive demand for integrated vision solutions that can seamlessly connect with other automation technologies. Emerging trends, including the rise of 3D vision systems and the increasing use of deep learning in image processing, will also shape the future landscape of the industrial vision market, ensuring that it remains at the forefront of technological innovation and operational excellence.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 8.50 Billion |

| Market Size Value In 2023 | USD 9.22 Billion |

| Growth Rate | 8.50% (2023-2032) |

Industrial Vision Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.