- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

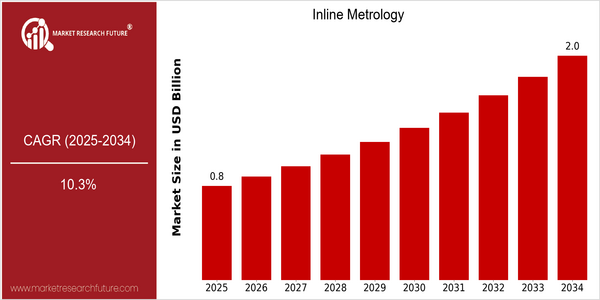

| Year | Value |

|---|---|

| 2025 | USD 0.81 Billion |

| 2034 | USD 1.96 Billion |

| CAGR (2025-2034) | 10.3 % |

Note – Market size depicts the revenue generated over the financial year

The In-line Metrology Market is expected to grow at a CAGR of 10.3% from 2025 to 2034. The high growth rate is due to the strong demand for high-precision measurement systems in various industries. The demand for high-precision measurement systems is due to the growing need for quality assurance and process optimization in manufacturing environments. In addition, the advancement of sensor technology and automation and the implementation of Industry 4.0 are driving the growth of the market. The rise of smart manufacturing and the Internet of Things is expected to boost the demand for in-line metrology systems. The leading companies in the in-line metrology market, such as Zeiss, Hexagon, Mitutoyo, and X-rite, are actively investing in research and development, forming strategic alliances, and launching new products to capture market share and meet customer needs. These initiatives will help the companies to meet the growing demand for in-line measurement systems and thus drive the market growth.

Regional Market Size

Regional Deep Dive

In-line Metrology is a fast-growing market across the globe, driven by the advancements in manufacturing technology and the increasing demand for accurate measurement solutions. In North America, the market is characterized by the presence of major players and a focus on automation and Industry 4.0 initiatives. In Europe, the market is characterized by stringent regulations and a high demand for quality and compliance. In Asia-Pacific, the market is characterised by a booming manufacturing sector and the rapid adoption of in-line metrology solutions. The Middle East and Africa are emerging as new opportunities for in-line metrology solutions as the manufacturing sector is modernized. Latin America is adopting these solutions slowly to increase the efficiency of its production.

Europe

- The European Union's stringent regulations on product quality and safety are compelling manufacturers to invest in inline metrology solutions, with companies like Zeiss and Mitutoyo at the forefront of innovation.

- The rise of smart factories in Germany and other industrial hubs is fostering the adoption of inline metrology technologies, as manufacturers seek to optimize production processes and reduce waste.

Asia Pacific

- China's rapid industrialization and focus on high-tech manufacturing are propelling the demand for inline metrology solutions, with local companies like Hitec Products making significant advancements in this field.

- The Japanese government is promoting initiatives to enhance manufacturing efficiency, which includes funding for research and development in inline metrology technologies, thus stimulating market growth.

Latin America

- Brazil's manufacturing sector is gradually modernizing, with government incentives aimed at boosting productivity, leading to a growing interest in inline metrology technologies.

- The rise of local manufacturing hubs in Mexico is fostering partnerships with global inline metrology providers, enhancing the availability of advanced measurement solutions in the region.

North America

- The integration of Industry 4.0 technologies is reshaping the Inline Metrology landscape, with companies like Hexagon Manufacturing Intelligence leading the charge in providing advanced solutions that enhance automation and data analytics.

- Recent regulatory changes in the automotive sector, particularly in the U.S., are pushing manufacturers to adopt inline metrology systems to ensure compliance with stringent quality standards, thereby driving market growth.

Middle East And Africa

- The UAE's Vision 2021 initiative is encouraging the adoption of advanced manufacturing technologies, including inline metrology, to diversify the economy and enhance industrial capabilities.

- South Africa is seeing increased investment in manufacturing infrastructure, which is driving the demand for inline metrology solutions to improve quality control and operational efficiency.

Did You Know?

“Inline metrology can reduce production errors by up to 90%, significantly lowering costs and improving product quality.” — Industry reports from the International Society of Automation

Segmental Market Size

In-line measurement is a growing market, driven by the increasing demand for precision measurement in the production process. This is primarily driven by the growing need for quality assurance on the production line, and the increasing importance of automation and real-time data analysis in Industry 4.0. In addition, higher safety and quality requirements in industries such as the automobile and aircraft industry are boosting the demand for in-line measurement. In-line measurement is currently in the phase of industrialization. With its advanced measurement technology, companies like Hexagon and Zeiss are leading the way. North America and Europe are notable regions where manufacturers are increasingly using in-line measurement to optimize production. The most important applications are on automobile assembly lines, in the manufacture of microelectronics, and in the production of aeronautical parts. The development of in-line measurement is influenced by trends such as the implementation of energy-efficient production and the digitalization of the manufacturing industry. Developments in technology, such as laser scanning and optical measurement systems, are defining the future of the market.

Future Outlook

The in-line metrology market is expected to increase from $800 million to $1.8 billion by 2025, a robust CAGR of 10.3%. It is driven by the increasing demand for accurate and precise measurements in the manufacturing sector, particularly in the automobile, aerospace and electronics industries. The companies are looking for more efficient and accurate production methods and want to improve their quality. In-line metrology will help optimize production and reduce waste. In 2025, in-line metrology will be used in more than 60% of the production lines, a significant increase in market penetration. The integration of artificial intelligence and machine learning into in-line metrology systems will also be a major growth driver. These new data-driven tools will enable manufacturers to analyze and predict the data in real time, which will optimize their operations and minimize downtime. Also, the implementation of Industry 4.0 by governments and the support they give to automation will create a favorable environment for the in-line metrology market. The emergence of smart factories and the growing emphasis on sustainable development will also play a significant role in the future of in-line metrology, making it an essential tool in the future of manufacturing.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 10.27% (2023-2030) |

Inline Metrologys Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.