- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

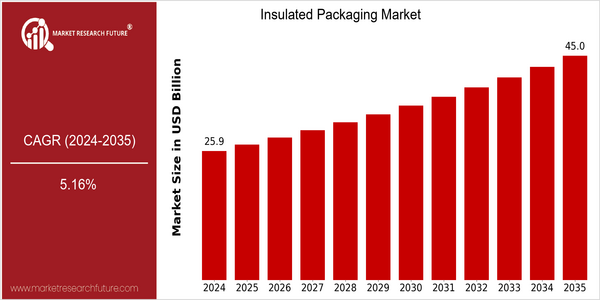

| Year | Value |

|---|---|

| 2024 | USD 25.86 Billion |

| 2035 | USD 44.98 Billion |

| CAGR (2025-2035) | 5.16 % |

Note – Market size depicts the revenue generated over the financial year

Insulated packaging is a market with high growth potential. The current market size of $28.64 billion in 2024 is projected to reach $48.61 billion by 2035. The annual average growth rate of 5.16% from 2025 to 2035 shows that the demand for insulated packaging solutions is high in various industries. The growing need for temperature-controlled products, especially in the food and pharmaceutical industries, is the main driver of this market growth. As consumers become more health-conscious and e-commerce grows, the demand for a good insulating package that can guarantee the quality of the product during transportation will increase. In addition, the development of materials and design is also a factor driving the growth of the market. Insulation materials with low energy consumption and smart packages that can monitor temperature and humidity are becoming more and more popular. The leading companies in the insulating package market, such as Sealed Air, Sonoco, and Amcor, are constantly investing in research and development to improve their product offerings. These companies are also pursuing strategic cooperation and new product development. The launch of the new product. , the acquisition of the company, and the establishment of strategic alliances, etc., are also in line with the development trend of the insulating package, and they are also driving the development of the market.

Regional Market Size

Regional Deep Dive

The insulating packaging market is growing significantly in various regions of the world. This is mainly due to the increasing demand for temperature-sensitive products, especially in the food and pharmaceutical industries. In North America, the market is characterized by a high degree of innovation and sustainability. Companies are investing heavily in sustainable materials and the latest technological developments. Europe has a strong regulatory framework, which encourages the use of insulating packaging. In Asia-Pacific, rapid urbanization and the growth of e-commerce are also driving the market. The Middle East and Africa are gradually adopting insulating packaging solutions, driven by the increasing demand for perishable goods. Latin America is focusing on improving logistics and the safety and quality of its products.

Europe

- The European Union's Green Deal is pushing for stricter regulations on packaging waste, prompting companies to innovate in the insulated packaging sector by developing recyclable and reusable materials.

- Organizations like the European Institute of Innovation and Technology (EIT) are funding projects aimed at enhancing the efficiency of insulated packaging solutions, particularly in the food supply chain, to reduce waste and improve sustainability.

Asia Pacific

- The rapid growth of e-commerce in countries like China and India is driving demand for insulated packaging solutions, as companies seek to ensure the safe delivery of temperature-sensitive products.

- Innovations in smart packaging technologies, such as temperature indicators and RFID tracking, are being adopted by key players like Amcor and Sealed Air to enhance the monitoring of perishable goods during transit.

Latin America

- The Latin American market is witnessing a shift towards more advanced insulated packaging solutions, driven by the need to improve logistics and reduce spoilage in the food supply chain.

- Local companies are collaborating with international firms to enhance their insulated packaging capabilities, with projects focusing on the development of cost-effective and sustainable materials.

North America

- The U.S. Food and Drug Administration (FDA) has introduced new guidelines for temperature-controlled packaging, encouraging companies to adopt more efficient insulated packaging solutions to ensure product safety during transportation.

- The main companies like Sonoco Products and Sealed Air have made substantial R&D investments to develop sustainable insulating materials, such as biodegradable and recyclable materials, in response to consumers’ demand for eco-friendly products.

Middle East And Africa

- The increasing demand for fresh produce and pharmaceuticals in the region is leading to a rise in insulated packaging solutions, with companies like Cold Chain Technologies expanding their operations to meet this need.

- Government initiatives aimed at improving food safety standards are encouraging the adoption of insulated packaging, particularly in countries like South Africa and the UAE, where food waste is a significant concern.

Did You Know?

“Approximately 30% of food produced globally is wasted due to inadequate packaging and transportation methods, highlighting the critical role of insulated packaging in reducing food spoilage.” — Food and Agriculture Organization (FAO)

Segmental Market Size

The insulated packaging market is growing steadily, driven by the rising demand for temperature-sensitive products in different industries. This demand is mainly driven by a growing preference for fresh and perishable products, coupled with stricter government regulations to ensure product safety during transportation. Also, the advancing material science is enhancing the effectiveness of insulated packaging. At present, the insulated packaging market is in its early growth stage. Sonoco Products Company and Sealed Air Corp. are the leading players in this field. The key applications of insulated packaging are in the transportation of food and beverages, pharmaceuticals, and e-commerce, where product safety is paramount. Insulated packaging has been especially successful in transporting vaccines and other temperature-sensitive drugs. This was brought home by the recent COVID pandemic. In addition, the trend towards the use of sustainable materials is driving the insulated packaging market. The insulating properties of phase-change materials and vacuum-insulating materials are improving, thus reducing the impact on the environment.

Future Outlook

Insulated packaging is a market that is set to grow from 2024 to 2035, with a projected CAGR of 5.16%. This growth is attributed to the increasing demand for temperature-sensitive products in various industries such as pharmaceuticals, food and beverages, and e-commerce. Insulated packaging is set to penetrate further into these markets. It is estimated that by 2035, it will account for over 60% of the temperature-controlled packaging market in the food delivery sector and 75% of the temperature-controlled packaging market in the pharmaceuticals industry. Meanwhile, technological advancements such as the development of eco-friendly insulating materials and smart packaging solutions will also be expected to drive the market. The use of biodegradable and recyclable materials will not only address the concern for the environment but also help meet the UN’s sustainable development goals. Also driving the market are the government’s policies aimed at reducing food wastage and improving the efficiency of supply chains. These policies are likely to encourage the use of sustainable practices and a greater use of insulated packaging in the distribution of temperature-sensitive products.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 13.9 Billion |

| Market Size Value In 2023 | USD 14.84 Billion |

| Growth Rate | 6.80% (2023-2032) |

Insulated Packaging Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.