- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

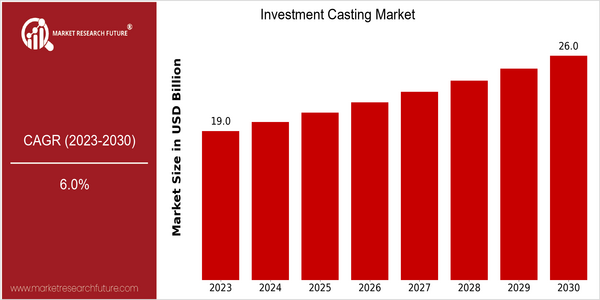

| Year | Value |

|---|---|

| 2023 | USD 19.0 Billion |

| 2030 | USD 26.0 Billion |

| CAGR (2023-2030) | 6.0 % |

Note – Market size depicts the revenue generated over the financial year

In the year 2023, the world investment casting market is valued at about $ 19 billion and is expected to reach $ 26 billion by 2030, growing at a CAGR of 6.0% from 2023 to 2030. This growth is mainly due to the growing demand for precision components in the fields of aerospace, automobiles and medical care. Also, the application of 3D printing and automation has improved the efficiency of the process and reduced the lead time. The market is also driven by the increasing demand for lightweight and high-strength materials, which are essential for improving the fuel efficiency and performance of automobiles and aircraft. In addition, the trend of miniaturization in the field of electrical appliances and medical devices has also driven the demand for precision investment casting components. Also, some of the leading companies in the field of investment casting, such as Precision Castparts Corp., Alcoa Corp. and Thyssenkrupp AG, are actively investing in new technology, establishing strategic cooperation, and enhancing their product offerings and market positions. These are all signs of the dynamic investment casting market, where innovation and collaboration are the main ways to seize emerging opportunities.

Regional Market Size

Regional Deep Dive

The market for investment castings is experiencing significant growth in various regions, driven by technological advancements, increasing demand from end-use industries, and a shift towards lightweight materials. Each region has its own unique characteristics, influenced by local economic conditions, regulations, and industrial capabilities. North America leads in innovation and technological uptake, while Europe focuses on sustainable and regulatory compliance. The Asia-Pacific region is growing rapidly, mainly driven by industrialization and the development of transport and power grids. The Middle East and Africa are investing in industrialization, and Latin America is becoming a competitive region with its abundance of natural resources and low costs.

Europe

- The question of the conservation of the environment is gaining in importance in Europe. The observance of the strictest regulations by the European Union leads to a great demand for the use of re-usable materials in the process of casting, which has led to the innovations of Thyssenkrupp and Siemens.

- The region is also seeing increased collaboration between industry and academia, with initiatives like the European Institute of Innovation and Technology (EIT) fostering research and development in advanced manufacturing technologies.

Asia Pacific

- In the countries of the Asia- Pacific region, especially in China and India, where government-supported “Make in India” programs are strengthening local manufacturing, investment casting is gaining ground.

- Technological advancements, including the adoption of 3D printing in investment casting processes, are being spearheaded by companies like Hitachi Metals, which is expected to enhance production efficiency and reduce lead times.

Latin America

- Latin America is emerging as a competitive player in the investment casting market, with countries like Brazil and Mexico focusing on resource availability and cost advantages to attract foreign investment.

- The region is also witnessing a rise in local manufacturing capabilities, with companies like Metalúrgica de Monterrey investing in advanced casting technologies to meet the growing demand from the automotive and aerospace sectors.

North America

- The North American market is heavily influenced by the aerospace and automotive sectors, with companies like Precision Castparts Corp. and Alcoa investing in advanced casting technologies to enhance production efficiency and material performance.

- Recent regulatory changes aimed at reducing carbon emissions are pushing manufacturers to adopt more sustainable practices, such as using eco-friendly materials and processes, which is expected to reshape the competitive landscape.

Middle East And Africa

- Gulf Casting Company is one of the most important of these. The growing construction and automobile industries in the United Arab Emirates and in Saudi Arabia are boosting the growth of investment casting.

- The African market is gradually evolving, with initiatives aimed at developing local manufacturing capabilities, supported by government programs that encourage foreign investment in the casting sector.

Did You Know?

“Investment casting, also known as lost-wax casting, dates back over 5,000 years and was used in ancient civilizations for creating intricate metal objects.” — American Foundry Society

Segmental Market Size

In the investment casting market, the key role of the technology in producing complex and highly precise metal parts for the aircraft, automobile and medical device industries is driving growth. The need for lightweight materials to increase the efficiency of transport and the increasing use of advanced manufacturing techniques to improve efficiency and reduce waste are also key drivers of demand. In addition, government regulations in favour of sustainable manufacturing practices are further increasing the importance of this technology. At present, the use of investment casting is in its mature phase, with companies such as GE Aviation and Boeing leading the way in deploying the technology to produce high-performance components. The versatility of the technology is demonstrated by the use of investment casting in the manufacture of jet engine blades and intricate medical components. The drive towards greater sustainability and the use of Industry 4.0, automation and artificial intelligence, are also expected to drive growth. The development of new alloys and their application to the production of complex and durable parts are shaping the future of investment casting.

Future Outlook

The investment casting market will grow from $ 19.0 billion in 2023 to $ 26.0 billion in 2030, at a robust compound annual growth rate (CAGR) of 6.0%. The main reason for this growth is the growing demand for precision parts in various industries, such as aerospace, automobiles and medical devices. The performance and quality of products are constantly being improved, and the material used is being reduced. In order to produce complex-shaped parts with a high surface finish, the method of investment casting is becoming more and more attractive. In these industries, investment casting penetration will be about 30% in 2030, mainly because of the improvement in materials and processes that reduce costs and increase efficiency. The key technological drivers, such as the combination of additive manufacturing and the development of new alloys, will further enhance the capabilities of investment casting. Also, the stricter regulations on reducing carbon emissions and promoting sustainable manufacturing will encourage the use of investment casting, which is more energy-efficient than other methods. The increasing use of automation and digitalization in the manufacturing process will also be a key factor in shaping the future of the investment casting market. The efficiency and scalability of investment casting will increase with the development of smart manufacturing.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 15 Billion |

| Market Size Value In 2023 | USD 19 Billion |

| Growth Rate | 6.00% (2023-2030) |

Investment Casting Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.