- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

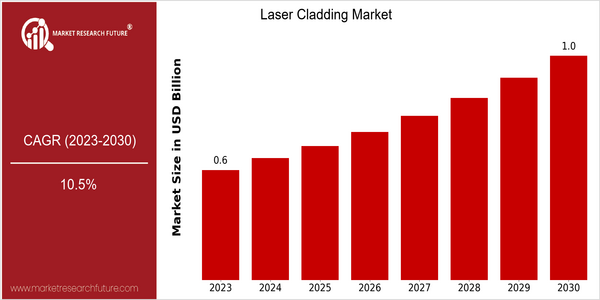

Laser Cladding Market Size Snapshot

| Year | Value |

|---|---|

| 2023 | USD 0.5525 Billion |

| 2030 | USD 1.005786 Billion |

| CAGR (2023-2030) | 10.5 % |

Note – Market size depicts the revenue generated over the financial year

The global market for cladding with laser is estimated to reach $ 0.5525 billion by 2023 and is projected to reach $ 1.0 billion by 2030. This growth curve represents a CAGR of 10.5% from 2023 to 2030. The growing demand for advanced manufacturing processes, coupled with the need to improve the surface properties of materials in various applications, is the main cause of this upward trend. There are many factors contributing to the growth of the cladding market. Among them, the technological advances in the field of materials and the use of lasers, which allow more precise and efficient cladding processes, are of great importance for the industry. aeronautics, automotive and energy. The growing emphasis on the reduction of waste in the manufacturing process is also expected to increase the adoption of cladding. The main companies in the market, such as Trumpf, Coherent and DMG Mori, are investing heavily in R & D, establishing strategic alliances and launching new products to strengthen their market position and take advantage of emerging opportunities.

Regional Deep Dive

Laser Cladding Market is a new and growing market, which is mainly driven by technological advancements and the increasing demand for surface cladding solutions. In North America, the market is characterized by the strong presence of key players and the focus on innovation, especially in the fields of aviation and automobiles. Europe, with the increasing number of regulations and the push for sustainable practices, is experiencing a rapid increase in the adoption of cladding. The Asia-Pacific region is growing rapidly, mainly driven by the growth of industry and the investment in advanced manufacturing. Middle East and Africa, especially in the oil and gas industry, are the main growth areas; Latin America is gradually embracing this technology as its industries modernize.

North America

- The United States Department of Energy is promoting the development of advanced manufacturing technology, including laser cladding, which will help domestic industry to compete in the global marketplace.

- Companies such as Optomec and Trumpf are at the forefront of this development. Their efforts are focused on improving the efficiency of the cladding process and reducing the cost of production. This has encouraged more and more industries to adopt the technology.

- The American aeronautics industry is increasingly turning to laser cladding to repair and maintain components, mainly because of the need for cost-effective and sustainable solutions.

Europe

- The European Community has put in place regulations aimed at reducing carbon emissions. This has led to the adoption of a more sustainable alternative to the traditional way of applying coatings.

- In the cladding field, major players such as DMG Mori and Renishaw are investing in research and development to develop the latest laser cladding techniques, which will improve the quality and precision of surface treatments.

- Germany and the United Kingdom are the pioneers in the field of laser welding in the automobile industry, with the aim of increasing the service life and performance of the parts.

Asia-Pacific

- The rapid industrialization of China, the support of the state for advanced manufacturing, and the development of the aviation and energy industries, are the main driving forces of the development of laser welding.

- Han’s Laser and Wuhan Huagong Tech are making great strides in developing cost-effective cladding solutions for local industries.

- In the region the tendency towards automation and the adoption of smart manufacturing is growing, and the use of a cladding process by means of a laser is an example of this.

MEA

- The Middle East oil industry is increasingly using laser cladding to repair drilling equipment, because it offers improved resistance to the harsh conditions of the environment.

- In countries like Saudi Arabia, the government has begun to encourage the use of advanced manufacturing methods, such as laser cladding, in order to diversify the economy away from oil.

- The question of the length of service of mining machinery is of the utmost importance to the resource-based economies of Africa.

Latin America

- Brazil is seeing a gradual increase in the use of laser welding in the automobile and industrial sectors, supported by the local companies investing in the modernization of their manufacturing.

- The region is also characterized by a strong orientation towards modernization and efficiency in the field of production, which has led to an increased interest in the process of cladding by means of the so-called “laser cladding.”

- In the United States, government programs to improve the competitiveness of industry are encouraging the development of newer and more efficient production methods, such as the use of laser cladding.

Did You Know?

“It is also known that by the welding of a metallic material by means of a special apparatus, the wear resistance of a component is increased by up to three hundred per cent, which is a very effective means of extending the life of a component.” — International Journal of Advanced Manufacturing Technology

Segmental Market Size

The cladding market is currently experiencing rapid growth, driven by the rising demand for advanced surface engineering solutions. This market plays a crucial role in enhancing the performance and lifespan of components in many industries, including aerospace, automotive, and energy. The main drivers of the market are the need for improved wear and corrosion resistance in critical applications, and the increasing use of additive manufacturing processes, which complement cladding.

The use of this process is now passing from a laboratory stage to a stage of practical application. The leaders, such as Siemens and GE Aviation, are already using it in their manufacturing processes. The main applications are for the repair of aero-engine blades and for the repair of moulds in the car industry. The development of the industry is being driven by the need for more efficient and sustainable manufacturing, and the development of fibre lasers and high-power diode lasers.

Future Outlook

The laser cladding market is set to grow at a CAGR of 10.5% from 2023 to 2030, with a market size of $ 551 million in 2023, rising to $ 912 million in 2030. This growth will be driven by the increasing demand for advanced manufacturing processes in a number of industries, such as aerospace, automotive and energy. The growing need to enhance the performance and the life of components is driving the use of laser cladding in surface repair and resurfacing applications. As a result, the technology is expected to see a higher penetration in these industries.

Developments in high-power lasers and improved powder feedstocks will further drive growth. Moreover, the growing focus on sustainability and resource efficiency is expected to drive the adoption of laser cladding as a more environmentally friendly alternative to traditional coating methods. Also, the integration of automation and artificial intelligence into the process will increase the efficiency and reduce the costs of the cladding process, making it more affordable for more manufacturers. This will result in a transformative phase for the market, which will be characterized by innovation and greater market penetration across industries.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 0.5 Billion |

| Market Size Value In 2023 | USD 0.5525 Billion |

| Growth Rate | 10.50% (2023-2030) |

Laser Cladding Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.