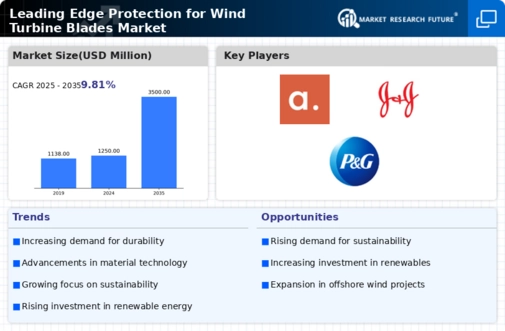

Leading Edge Protection for Wind Turbine Blades Market Summary

The Global Leading Edge Protection for Wind Turbine Blades Market is projected to grow significantly from 1250 USD Million in 2024 to 3500 USD Million by 2035.

Key Market Trends & Highlights

Leading Edge Protection for Wind Turbine Blades Key Trends and Highlights

- The market is expected to experience a compound annual growth rate (CAGR) of 9.81 percent from 2025 to 2035.

- By 2035, the market valuation is anticipated to reach 3500 USD Million, indicating robust growth opportunities.

- In 2024, the market is valued at 1250 USD Million, reflecting the increasing demand for advanced protective solutions.

- Growing adoption of leading edge protection technologies due to the need for enhanced durability and efficiency is a major market driver.

Market Size & Forecast

| 2024 Market Size | 1250 (USD Million) |

| 2035 Market Size | 3500 (USD Million) |

| CAGR (2025 - 2035) | 9.81% |

Major Players

Apple Inc (US), Microsoft Corp (US), Amazon.com Inc (US), Alphabet Inc (US), Berkshire Hathaway Inc (US), Tesla Inc (US), Meta Platforms Inc (US), Johnson & Johnson (US), Visa Inc (US), Procter & Gamble Co (US)

Leave a Comment