- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

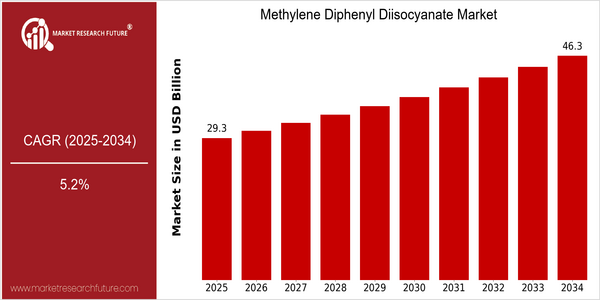

Methylene Diphenyl Diisocyanate Market Size Snapshot

| Year | Value |

|---|---|

| 2025 | USD 29.34 Billion |

| 2034 | USD 46.31 Billion |

| CAGR (2025-2034) | 5.2 % |

Note – Market size depicts the revenue generated over the financial year

Methylene diphenyl diisocyanate (MDI) is the main ingredient of isocyanates. The current market size of MDI is expected to be $29,341 million in 2025 and is expected to grow to $46 billion by 2034. This represents a compound annual growth rate (CAGR) of 5.2%. This growth can be attributed to the growing demand for MDI in various applications, especially in the manufacture of polyurethane foams, which are widely used in the construction, automobile and furniture industries. Energy efficiency and the need to develop sustainable industry have become the industry's major concerns. Therefore, the versatility of MDI as a raw material for high-performance materials is increasingly important. Besides, the development of technology and the improvement of production methods will also promote the growth of the market. The performance of MDI-based products has been improved and their impact on the environment has been reduced. The company has invested a lot of research and development efforts to improve the performance of MDI-based products. The main market players in the MDI market, such as BASF, Covestro and Huntsman, have established strategic cooperation and launched new products to strengthen their market positions. For example, BASF has recently expanded its production capacity for MDI, which is an indication of its commitment to sustainable development and the need to meet the growing demand for MDI. The future of the MDI market is bright.

Regional Deep Dive

Methylene diphenyl diisocyanate (MDI) is a chemical compound that is used in the production of isocyanates. It is used in many industries, including the manufacture of polyurethane, polyurea, and polyurea. The North American market is mainly driven by the construction industry and the growing demand for polyurethane products. In Europe, the focus is on innovation and the development of green chemistry. The Asia-Pacific region is characterised by the rapid industrialisation and urbanisation, which increases the demand for MDI in a number of applications, especially in the automotive and construction industries. The Middle East and Africa (MEA) are growing due to the growing demand for infrastructure. Latin America is gradually adopting MDI in its manufacturing processes, driven by economic recovery and investments in the industrial sector.

North America

- The United States Environmental Protection Agency has regulated the emissions of chemicals and forced manufacturers to develop low-emission MDI production technology, which is expected to increase the competitiveness of the market.

- With companies such as BASF and Covestro, new production processes are being introduced that increase efficiency and reduce the environment's impact.

- The growing demand for energy-efficient building materials is resulting in the use of methyldithiolates in the construction of green buildings, which is expected to further drive the market.

Europe

- The REACH regulation is influencing the market for mineral spirits in that it requires manufacturers to submit detailed safety data, which is forcing companies to invest in safer and more sustainable production methods.

- The development of bio-based alternatives to methyl diisopropyl is gaining ground, with companies like Huntsman developing products that reduce the use of fossil fuels and thus reflecting the region’s commitment to sustainable development.

- Consequently, the trend towards lightweight construction in the automobile industry is driving the demand for m-di-based composites and this is resulting in a significant increase in the market for the same.

Asia-Pacific

- The rapid development of urbanization and the construction industry in China has made it the main growth engine in the region.

- The government of India, in accordance with the policy of “Make in India,” is encouraging the manufacture of M-DI locally. This is expected to reduce the country’s dependence on imports and stimulate the growth of the domestic market.

- Competition will be increased and innovation will be encouraged.

MEA

- The United Arab Emirates’ Vision 2021 plan for the development of its economy and the improvement of its infrastructure is a key factor driving the growth of the methyl-di-isocyanate (MDI) market.

- The National Industrial Development and Logistics Program (NIDLOG) is promoting investment in the chemical industry, especially in the manufacture of methyl isobutyl ketone, which is expected to increase the country's manufacturing capacity.

- The special climate conditions in the region require the use of high-quality insulating materials, thus increasing the demand for methyldichloride in construction and energy-saving projects.

Latin America

- Brazil's economic recovery has led to a rise in investments in the building sector, which is expected to increase the demand for m-di in building materials.

- Mexico's growing automobile industry is using more and more of the lightweight components it makes with the help of MDI.

- Government initiatives to promote sustainable practices are expected to boost the use of MDI in eco-friendly products, which will in turn drive the market.

Did You Know?

“Methylene diphenyl diisocyanate (MDI) is the key raw material for the production of flexible and rigid polyurethane foams, which are used in a variety of applications from furniture to automobile parts.” — Polyurethane Manufacturers Association

Segmental Market Size

The Methylene Diphenyl Diisocyanate (MDI) segment plays a key role in the polyurethane market, as it is mainly used in the production of flexible and rigid foams. It is currently experiencing stable growth, driven by the rising demand from the construction, automobile and furniture industries. This is mainly due to the growing need for energy-efficient insulating materials and the growing demand for lightweight components in the automobile industry in order to improve fuel efficiency.

At present the use of m-dimethylisobutyl ether is in a state of development, and the large chemical companies like BASF and Covestro have developed and are applying advanced production methods for maximum efficiency. In North America and Europe, where energy-efficiency regulations are stringent, the use of m-dimethylisobutyl ether is especially high. The most important products of m-dimethylisobutyl ether are insulating panels for buildings, car parts and foams for furniture. M-dimethylisobutyl ether is also used in the production of insulating materials for electrical appliances. Developments in production, such as the use of bio-based raw materials, are shaping the evolution of the market.

Future Outlook

The Methylenediphenyl Diisocyanate (MDI) market is forecast to grow at a CAGR of 5.2% from 2025 to 2034. This growth is driven by the rising demand for polyurethane products in the construction, automobile, and furniture industries. As the global economy grows, the penetration of these industries by MDI is expected to increase, driven by its superior properties such as flexibility, resistance, and heat resistance. In the construction industry alone, by 2034, the use of MDI is expected to account for more than 40% of the total consumption of the product, highlighting the importance of this chemical in modern building materials.

The technological and regulatory developments in the medical devices industry will further shape the market. In the production of the devices, the development of more efficient catalytic systems and the introduction of environmentally friendly manufacturing methods are expected to increase the yields and reduce emissions, thereby contributing to the sustainable development of the world. Also, the regulatory framework that encourages the use of low-emission materials is expected to increase the adoption of metered dose inhalers in various applications. The increasing focus on energy-efficient buildings and the growing popularity of lightweight automobile components will also contribute to the growth of the market. These trends will be reflected in the metered dose inhaler market, which will offer opportunities for the use of high-performance materials.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 5.20% (2023-2032) |

Methylene Diphenyl Diisocyanate Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.