- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

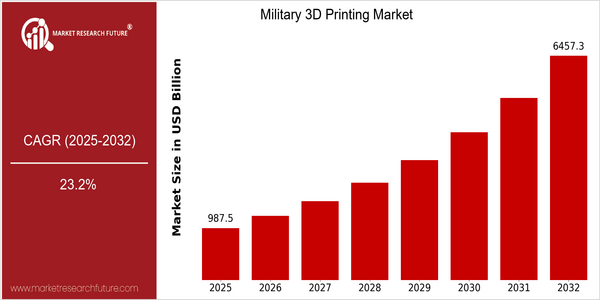

| Year | Value |

|---|---|

| 2025 | USD 987.54 Billion |

| 2032 | USD 6457.3 Billion |

| CAGR (2024-2032) | 23.2 % |

Note – Market size depicts the revenue generated over the financial year

The Military 3D Printing Market is poised for significant growth, with a current market size projected at USD 987.54 billion in 2025 and an impressive forecast of USD 6457.3 billion by 2032. This translates to a robust compound annual growth rate (CAGR) of 23.2% from 2024 to 2032, indicating a strong upward trajectory in the adoption of 3D printing technologies within military applications. The increasing demand for rapid prototyping, customized parts, and on-demand manufacturing capabilities are key drivers of this growth, as military organizations seek to enhance operational efficiency and reduce supply chain vulnerabilities. Technological advancements, such as the development of advanced materials and improved printing techniques, are further propelling the market forward. Companies like Lockheed Martin and Boeing are at the forefront of this innovation, investing in strategic partnerships and research initiatives to integrate 3D printing into their manufacturing processes. Additionally, the U.S. Department of Defense has been actively exploring 3D printing for producing spare parts and equipment in remote locations, which underscores the strategic importance of this technology in modern military operations. As these trends continue to evolve, the Military 3D Printing Market is expected to expand significantly, driven by both technological innovation and the pressing need for enhanced military capabilities.

Regional Market Size

Regional Deep Dive

The Military 3D Printing Market is experiencing significant growth across various regions, driven by advancements in technology, increasing demand for rapid prototyping, and the need for cost-effective manufacturing solutions. In North America, particularly the United States, the market is characterized by strong government support and investment in defense technologies, while Europe is witnessing a surge in collaborative projects among NATO countries. The Asia-Pacific region is rapidly adopting 3D printing technologies due to rising defense budgets and a focus on indigenous manufacturing capabilities. Meanwhile, the Middle East and Africa are exploring 3D printing to enhance military logistics and supply chain efficiency, and Latin America is beginning to recognize the potential of 3D printing in defense applications, albeit at a slower pace.

Europe

- The European Defence Agency (EDA) is promoting collaborative research projects in 3D printing, encouraging member states to share knowledge and resources to advance military applications of additive manufacturing.

- Countries like Germany and France are leading the way in developing regulations and standards for 3D printing in defense, which is expected to enhance interoperability and safety in military operations.

Asia Pacific

- China is rapidly advancing its military capabilities through 3D printing, with state-owned enterprises investing in additive manufacturing technologies to produce advanced weaponry and components.

- India's Defence Research and Development Organisation (DRDO) is actively exploring 3D printing for defense applications, including the development of drones and other critical military hardware, which is expected to bolster indigenous defense production.

Latin America

- Brazil is beginning to explore the use of 3D printing in defense applications, with initiatives aimed at developing local capabilities for producing military equipment and components.

- The region is witnessing increased interest from private companies in adopting 3D printing technologies, although government support and investment remain limited compared to other regions.

North America

- The U.S. Department of Defense has launched several initiatives, such as the Additive Manufacturing Strategy, aimed at integrating 3D printing into military operations to enhance supply chain resilience and reduce costs.

- Companies like Lockheed Martin and Boeing are investing heavily in 3D printing technologies, focusing on producing lightweight components for aircraft and other military equipment, which is expected to streamline production processes.

Middle East And Africa

- Countries like the UAE are investing in 3D printing technologies to enhance their military logistics, with projects aimed at producing spare parts on-demand to reduce dependency on foreign suppliers.

- Israel is leveraging 3D printing for rapid prototyping and production of military equipment, which is expected to improve operational readiness and reduce lead times for critical components.

Did You Know?

“Did you know that the U.S. Army has successfully used 3D printing to create a fully functional drone in just 24 hours, showcasing the technology's potential for rapid deployment in military operations?” — U.S. Army Research Laboratory

Segmental Market Size

The Military 3D Printing Market is experiencing significant growth, driven by the increasing demand for rapid prototyping and on-demand manufacturing capabilities within defense sectors. Key factors propelling this segment include the need for cost-effective production methods and the ability to create complex parts that traditional manufacturing cannot achieve. Additionally, regulatory policies promoting advanced manufacturing technologies further stimulate demand. Currently, the adoption stage of military 3D printing is in the scaled deployment phase, with notable examples including the U.S. Army's use of additive manufacturing for producing spare parts and the U.S. Navy's initiatives to print components on-demand aboard ships. Primary applications encompass the production of lightweight components, custom tools, and even entire drones, showcasing the versatility of 3D printing in military operations. Trends such as sustainability initiatives and the push for supply chain resilience, particularly highlighted during the COVID-19 pandemic, are accelerating growth. Technologies like metal and polymer 3D printing, along with advancements in materials science, are shaping the evolution of this segment.

Future Outlook

The Military 3D Printing Market is poised for remarkable growth from 2025 to 2032, with a projected market value soaring from $987.54 million to approximately $6.46 billion, reflecting a robust compound annual growth rate (CAGR) of 23.2%. This growth trajectory is underpinned by the increasing adoption of additive manufacturing technologies within military applications, driven by the need for rapid prototyping, supply chain efficiency, and the ability to produce complex components on-demand. As military organizations seek to enhance operational readiness and reduce logistical burdens, the penetration of 3D printing technologies is expected to rise significantly, with usage rates potentially reaching over 30% of all military manufacturing processes by 2032. Key technological advancements, such as the development of new materials and improved printing techniques, will further catalyze market expansion. Innovations in metal and polymer 3D printing are enabling the production of lightweight, durable components that meet stringent military specifications. Additionally, supportive government policies and increased defense budgets in various countries are likely to bolster investment in 3D printing capabilities. Emerging trends, including the integration of artificial intelligence and machine learning in the design and production processes, will also play a crucial role in shaping the future landscape of the military 3D printing market, ensuring that it remains at the forefront of modern military manufacturing solutions.

Military 3D Printing Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.