- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

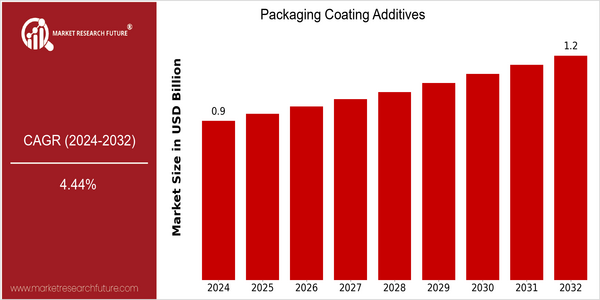

| Year | Value |

|---|---|

| 2024 | USD 0.88 Billion |

| 2032 | USD 1.25 Billion |

| CAGR (2024-2032) | 4.44 % |

Note – Market size depicts the revenue generated over the financial year

The market for coating additives is growing steadily, and the present market is valued at $ 880 million in 2024 and is projected to reach $1,250 million by 2032. The CAGR for this market is 4.44 percent. The growth of the market is attributed to the rising demand for sustainable packaging, advancements in coating technology, and the need to enhance product protection and shelf life. The shift toward bio-based and recyclable coating additives is increasing in importance. Several players in the market, such as BASF, Dow, and Evonik, are investing in R & D to develop new products. Strategic initiatives such as acquisitions and alliances are also reshaping the competitive landscape. In recent years, a large number of high-performance and environmentally friendly products have been launched, which reflect the trend of consumer preferences. The trend will continue in the future, and these factors will play a key role in the development of the market.

Regional Market Size

Regional Deep Dive

The Coating Additives Market is a market which is experiencing significant growth across the globe, owing to the increasing demand for sustainable packaging solutions and innovations in coating technology. In North America, the market is characterized by a strong focus on eco-friendly products and stringent regulatory standards, while in Europe, the focus is on advanced technology and sustainable practices. The Asia-Pacific region is characterized by rapid industrialization and urbanization, which has led to a significant increase in the demand for packaging solutions. In the Middle East and Africa, the adoption of modern packaging technology is being driven by the diversification of economies. Latin America is characterized by the growing purchasing power of consumers and the increasing trend toward more sophisticated packaging solutions.

Europe

- The European Union's Green Deal is driving the adoption of sustainable packaging solutions, leading to increased demand for biodegradable and recyclable coating additives.

- Innovations in nanotechnology are being explored by companies such as BASF and Evonik, enhancing the performance of packaging coatings and meeting stringent regulatory requirements.

Asia Pacific

- China's rapid growth in e-commerce is significantly boosting the demand for packaging solutions, prompting local manufacturers to invest in advanced coating technologies.

- India's government initiatives promoting 'Make in India' are encouraging domestic production of packaging materials, leading to increased competition and innovation in coating additives.

Latin America

- Brazil's increasing consumer awareness regarding sustainability is pushing manufacturers to adopt eco-friendly packaging solutions, including innovative coating additives.

- The rise of local startups focused on sustainable packaging is fostering innovation in the region, with companies like Tetra Pak leading the charge in developing new coating technologies.

North America

- The U.S. Environmental Protection Agency (EPA) has introduced new regulations aimed at reducing volatile organic compounds (VOCs) in packaging coatings, pushing manufacturers to innovate with low-VOC alternatives.

- Major companies like Sherwin-Williams and PPG Industries are investing in R&D to develop bio-based coating additives, reflecting a growing trend towards sustainability in packaging.

Middle East And Africa

- The UAE's Vision 2021 is fostering a shift towards sustainable packaging, with local companies exploring eco-friendly coating additives to align with national goals.

- South Africa's growing retail sector is driving demand for high-quality packaging solutions, prompting investments in advanced coating technologies by companies like Sappi.

Did You Know?

“Approximately 30% of all packaging materials produced globally are coated with additives to enhance their performance and sustainability.” — Smithers Pira

Segmental Market Size

The segment of packaging coating additives plays a crucial role in the quality and aesthetics of packaging materials and is currently experiencing stable growth. Demand for sustainable packaging solutions is driven by a rising preference among consumers for sustainable packaging solutions, as well as stricter legislation and stricter regulations on reducing the environment. Further technological developments, such as the development of bio-based additives, are driving this market forward. The packaging coating additives market is currently in a mature stage of development. Companies such as BASF and Dow are the leading companies in this market with their new product developments. The main application areas of packaging coating additives are in the field of food and beverage packaging, where the coatings are used to improve the barrier properties and shelf life of flexible packaging materials. The trend towards sustainability and the trend towards the use of eco-friendly materials are pushing the market forward. Nanotechnology and smart coatings are shaping the future of the market and enabling higher functionality and performance of the packaging materials.

Future Outlook

The aqueous coatings on the surface of the packages were to be the most widely used. The market value for the period from 2024 to 2032 was estimated to increase from $88 million to $125 million, a compound annual growth rate of 4.4 percent. The growth was mainly based on the increasing demand for sustainable packaging solutions, as manufacturers increasingly sought to improve the performance and environment of their products. This was also a consequence of the upcoming stricter regulations and the desire for sustainable solutions among consumers. This shift towards eco-friendly materials and coatings was to increase the penetration of the market and the use of the various packaging segments. The use of bio-based and high-performance additives was to change the packaging coating landscape. Nanotechnology and smart coatings, which offer enhanced barrier properties and functionality, were to gain in importance, meeting the evolving needs of the food, pharmaceutical and consumer goods industries. The increasing focus on reducing waste and increasing recyclability was to increase research and development, which was to create a competitive environment in which new products were to be introduced. These developments were to change the market for packaging coatings and offer opportunities for those who could adapt to the new conditions and meet the changing demands.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 0.8 Billion |

| Market Size Value In 2023 | USD 0.84 Billion |

| Growth Rate | 5.09% (2023-2032) |

Packaging Coating Additives Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.