- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

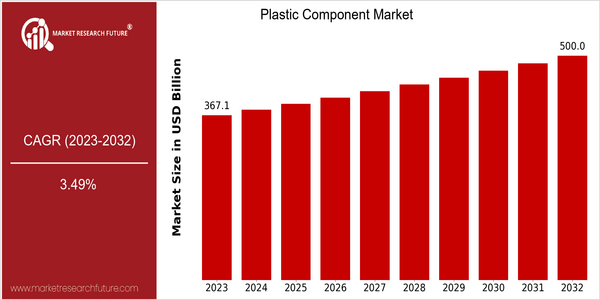

| Year | Value |

|---|---|

| 2023 | USD 367.07 Billion |

| 2032 | USD 500.0 Billion |

| CAGR (2024-2032) | 3.49 % |

Note – Market size depicts the revenue generated over the financial year

Among other things, the market for plastic components is expected to reach $367.07 billion in 2023 and reach $500 billion by 2032, at a CAGR of 3.49% from 2024 to 2032. This shows the constant demand for plastic components in various industries, due to their versatility, lightness and cost-effectiveness. The market is expected to grow further in the coming years, mainly due to the increasing use of plastic components in the automotive and household appliance industries. The use of plastics in these industries is expected to increase further due to technological developments in polymer chemistry, which improve the performance and environmental friendliness of plastics. The use of bioplastics and recycled plastics is increasing and aligns with the world's sustainable development goals and the regulatory environment. The major players in the market, such as BASF, The Dow Chemical Company and DuPont, are investing heavily in R & D to develop more sustainable and high-performance plastic solutions. Strategic alliances, such as cooperation and joint ventures, aimed at enhancing product offerings and expanding the market, also demonstrate the dynamic nature of the plastic components market.

Regional Market Size

Regional Deep Dive

The Plastic Components Market is experiencing a strong growth in various regions. This is mainly due to the increasing demand from end-use industries such as the automobile, electrical and electronics, and consumer goods industries. North America is characterized by an advanced manufacturing technology and a strong focus on the environment, while Europe is characterized by a high level of regulation and innovation in biodegradable plastics. The Asia-Pacific region is experiencing rapid industrialization and urbanization, which leads to an increase in the demand for plastic components. The Middle East and Africa are experiencing strong growth due to the development of the transport system, while Latin America is focusing on local production in order to reduce its dependence on imports. Each region has its own trends and opportunities.

Europe

- The European Union's stringent regulations on plastic waste are driving innovation in the development of biodegradable and recyclable plastic components, with companies like BASF and Covestro leading the charge.

- The European market is increasingly adopting circular economy principles, with initiatives such as the European Plastics Pact encouraging collaboration among stakeholders to reduce plastic waste and promote sustainable practices.

Asia Pacific

- China's ambitious 'Made in China 2025' initiative is pushing for advancements in plastic manufacturing technologies, with significant investments in R&D from companies like Sinopec and China National Petroleum Corporation.

- The growing consumer electronics market in countries like India and Japan is driving demand for high-performance plastic components, with local manufacturers focusing on innovation to meet the needs of tech companies.

Latin America

- Brazil's National Policy on Solid Waste is encouraging the use of recycled plastics in manufacturing, prompting companies to innovate in the production of plastic components that meet sustainability standards.

- The region is witnessing a surge in local startups focused on developing eco-friendly plastic alternatives, with initiatives supported by organizations like the Inter-American Development Bank to promote sustainable practices.

North America

- The rise of electric vehicles (EVs) has led to increased demand for lightweight plastic components, with companies like Tesla and General Motors investing heavily in innovative materials to enhance vehicle efficiency.

- Regulatory changes in the U.S. regarding single-use plastics are prompting manufacturers to explore alternative materials, with organizations such as the American Chemistry Council advocating for recycling initiatives and sustainable practices.

Middle East And Africa

- The UAE's Vision 2021 is promoting the development of a diversified economy, leading to increased investments in plastic manufacturing facilities and infrastructure projects that require plastic components.

- South Africa's Plastics Industry Master Plan aims to enhance local production capabilities and reduce reliance on imports, fostering growth in the domestic plastic component market.

Did You Know?

“Approximately 300 million tons of plastic are produced globally each year, with a significant portion used in manufacturing components for various industries.” — PlasticsEurope

Segmental Market Size

The plastic component market is currently experiencing a steady growth. This growth is driven by an increase in demand from industries such as the automobile industry, the consumer goods industry, and the medical industry. Among the main reasons for this growth are the increasing consumer demand for lightweight materials, which improve the fuel efficiency of automobiles, and the increasingly stringent regulations on the reduction of carbon dioxide emissions. Also, advances in the manufacturing process such as injection molding and 3D printing have made it possible to produce complex, high-performance plastic components. These advances have led to the market for such plastic components reaching a stage of maturity, with companies such as BASF and DuPont leading the way in the development of new applications. The use of plastic components is now becoming a basic part of the functionality and design of such products as automobile parts, medical devices, and packaging. Also, the trend toward a circular economy and the drive for sustainability are expected to accelerate the growth of the market as companies develop new materials that can be biodegraded or recycled. The development of such new materials as bioplastics and smart polymers is shaping the evolution of the market, enabling manufacturers to meet both the requirements of consumers and the requirements of the government.

Future Outlook

The plastics component market is expected to grow at a steady rate from 2023 to 2032, with an increase from $367.07 billion to $500 billion, at a compound annual growth rate (CAGR) of 3.49%. The growth is driven by the increasing demand for lightweight and durable materials in the automobile, consumer goods and electric industries. As the manufacturers pay more and more attention to the concept of sustainable development, the use of recycled plastics and bioplastics is expected to increase, which will also promote the growth of the market. By 2032, the proportion of recycled plastics in the total consumption of plastic components is expected to exceed 20%, which will be a significant indicator of the implementation of the circular economy. The development of advanced polymer composites and 3D printing will bring revolutionary changes to the production process of plastic components. The performance of products will not only be improved, but also the waste and energy will be reduced, which is in line with the sustainable development of the earth. In addition, government support to reduce plastic waste and promote green materials will also boost market growth. The development of smart plastics and the application of the Internet of Things (IoT) will also have a significant impact on the development of the market. The future of the plastics component market is bright. The main driving forces are: technological progress, government support and the trend of consumption.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | 11.41% |

Plastic Component Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.