- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

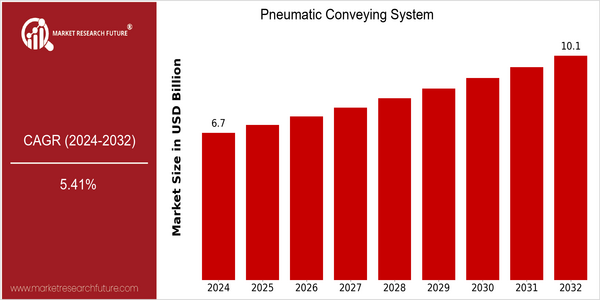

| Year | Value |

|---|---|

| 2024 | USD 6.65 Billion |

| 2032 | USD 10.13 Billion |

| CAGR (2024-2032) | 5.41 % |

Note – Market size depicts the revenue generated over the financial year

The global pneumatic conveying system market is poised for significant growth, with a current market size of USD 6.65 billion in 2024, projected to expand to USD 10.13 billion by 2032. This growth trajectory reflects a compound annual growth rate (CAGR) of 5.41% over the forecast period from 2024 to 2032. The increasing demand for efficient material handling solutions across various industries, including food and beverage, pharmaceuticals, and chemicals, is a primary driver of this market expansion. As industries seek to enhance operational efficiency and reduce labor costs, pneumatic conveying systems offer a reliable solution for the transportation of bulk materials with minimal contamination and waste. Technological advancements, such as the integration of automation and IoT capabilities into pneumatic conveying systems, are further propelling market growth. These innovations enable real-time monitoring and optimization of conveying processes, leading to improved productivity and reduced downtime. Key players in the market, including Schenck Process, Nilfisk, and Coperion, are actively investing in research and development to enhance their product offerings and maintain competitive advantages. Strategic initiatives, such as partnerships and collaborations aimed at expanding product portfolios and entering new markets, are also shaping the landscape of the pneumatic conveying system market.

Regional Market Size

Regional Deep Dive

The Pneumatic Conveying System Market is experiencing significant growth across various regions, driven by increasing demand for efficient material handling solutions in industries such as food processing, pharmaceuticals, and chemicals. Each region exhibits unique characteristics influenced by local industrial activities, regulatory frameworks, and technological advancements. North America is characterized by a strong focus on automation and innovation, while Europe emphasizes sustainability and compliance with stringent regulations. The Asia-Pacific region is witnessing rapid industrialization, leading to heightened demand for pneumatic conveying systems, whereas the Middle East and Africa are gradually adopting these technologies to enhance operational efficiency. Latin America is also emerging as a potential market due to growing investments in infrastructure and manufacturing sectors.

Europe

- In Europe, the market is heavily influenced by the EU's Green Deal, which aims to make the continent climate-neutral by 2050. This has led to increased investments in sustainable pneumatic conveying technologies, with companies like Nilfisk and Schenck Process developing eco-friendly solutions.

- The rise of Industry 4.0 in Europe is driving the integration of smart technologies into pneumatic conveying systems, enhancing their efficiency and reliability. This trend is supported by various government initiatives promoting digital transformation in manufacturing.

Asia Pacific

- The Asia-Pacific region is witnessing rapid industrial growth, particularly in countries like China and India, which are investing heavily in manufacturing and infrastructure. This has led to a significant increase in demand for pneumatic conveying systems, with companies like H-P Products and Schenck Process expanding their operations in these markets.

- Government initiatives aimed at boosting the manufacturing sector, such as 'Make in India' and 'Made in China 2025', are further propelling the adoption of pneumatic conveying systems, as industries seek to enhance productivity and efficiency.

Latin America

- Latin America is emerging as a potential market for pneumatic conveying systems, driven by growing investments in infrastructure and manufacturing, particularly in Brazil and Mexico. Companies like Schenck Process are expanding their presence to cater to this rising demand.

- The region's economic recovery post-pandemic is leading to increased industrial activity, which is expected to boost the adoption of pneumatic conveying systems as manufacturers seek to enhance operational efficiency.

North America

- The North American market is seeing a surge in demand for advanced pneumatic conveying systems, particularly in the food and beverage sector, driven by the need for automation and efficiency. Companies like Schenck Process and Pneumatic Conveying Systems, Inc. are leading innovations in this space, focusing on energy-efficient solutions.

- Recent regulatory changes in the U.S. regarding food safety and environmental standards are pushing manufacturers to adopt more sophisticated pneumatic conveying systems that comply with these regulations, thereby enhancing market growth.

Middle East And Africa

- In the Middle East and Africa, the market is gradually evolving, with increasing investments in the oil and gas, and mining sectors driving demand for pneumatic conveying systems. Companies like FLSmidth and Schenck Process are actively participating in projects aimed at improving material handling efficiency.

- The region's unique economic factors, such as fluctuating oil prices and a growing focus on diversification away from oil dependency, are influencing the adoption of pneumatic conveying systems as industries seek to optimize operations.

Did You Know?

“Did you know that pneumatic conveying systems can transport materials over distances of up to several kilometers, making them an efficient solution for large-scale industrial operations?” — Pneumatic Conveying Design Guide, 2023

Segmental Market Size

The Pneumatic Conveying System segment plays a crucial role in the material handling industry, currently experiencing stable growth due to increasing demand for efficient bulk material transport. Key drivers include the rising need for automation in manufacturing processes and stringent regulatory policies aimed at improving workplace safety and reducing dust emissions. Additionally, technological advancements in system design and control mechanisms enhance operational efficiency, further fueling demand. Currently, the adoption stage of pneumatic conveying systems is in the scaled deployment phase, with notable examples including companies like Schenck Process and Nilfisk, which have implemented these systems in various industries such as food processing and pharmaceuticals. Primary applications include the transport of powders, granules, and bulk solids, particularly in sectors like chemicals and food & beverage. Trends such as sustainability initiatives and the push for Industry 4.0 are accelerating growth, as companies seek to optimize resource use and minimize environmental impact. Relevant technologies shaping this segment include advanced sensors for real-time monitoring and automation software that integrates with existing manufacturing systems.

Future Outlook

The Pneumatic Conveying System market is poised for significant growth from 2024 to 2032, with a projected market value increase from $6.65 billion to $10.13 billion, reflecting a robust compound annual growth rate (CAGR) of 5.41%. This growth trajectory is underpinned by the rising demand for efficient material handling solutions across various industries, including food and beverage, pharmaceuticals, and chemicals. As industries increasingly prioritize automation and operational efficiency, the adoption of pneumatic conveying systems is expected to penetrate deeper into these sectors, with usage rates potentially reaching upwards of 30% in key applications by 2032. Key technological advancements, such as the integration of IoT and AI in pneumatic systems, are anticipated to drive market evolution. These innovations will enhance system performance, optimize energy consumption, and improve predictive maintenance capabilities, thereby reducing operational costs. Additionally, stringent regulations regarding workplace safety and environmental sustainability are likely to propel the demand for advanced pneumatic conveying solutions that minimize dust emissions and ensure safe material transport. As a result, the market will not only expand in size but also evolve in sophistication, catering to the growing needs for smart, sustainable, and efficient material handling solutions.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 5.9 Billion |

| Market Size Value In 2023 | USD 6.26 Billion |

| Growth Rate | 6.19% (2023-2032) |

Pneumatic Conveying System Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.