- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

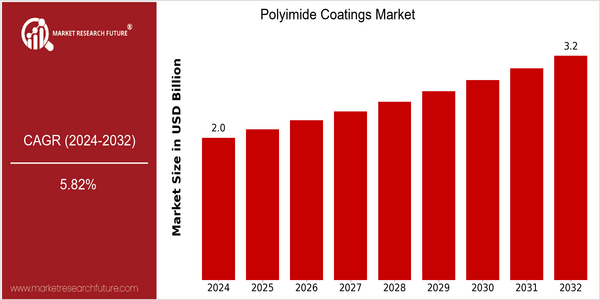

| Year | Value |

|---|---|

| 2024 | USD 2.05 Billion |

| 2032 | USD 3.22 Billion |

| CAGR (2024-2032) | 5.82 % |

Note – Market size depicts the revenue generated over the financial year

The market for polyimide coatings is growing at a fast pace. The market for polyimide coatings is expected to grow from $ 2.05 billion in 2024 to $ 3.22 billion by 2032. This growth rate will be 5.82% during the forecast period. The main reason for this is the increasing demand for high-performance materials in various industries, such as electronics, automobiles and aeronautics. Polyimide coatings are characterized by their excellent chemical and mechanical properties, which makes them particularly suitable for use in harsh environments. Further market growth is being driven by technological innovations and innovations in polyimide formulations. Various new coatings with improved adhesion and wear resistance are in development. DuPont, Kaneka, Saint-Gobain and other companies are launching new products and entering into strategic alliances to strengthen their position in the market. These efforts not only meet the needs of end users, but also respond to the trend towards sustainable and resource-efficient production, which further supports the market growth of polyimide coatings.

Regional Market Size

Regional Deep Dive

The polyimide market is characterized by its various applications in several industries, including the aeronautical, electronic and automobile industries. The regional markets are characterised by the unique nature of the manufacturing processes, the technological developments and the regulatory frameworks. The demand for high-performance coatings resistant to extreme temperatures and harsh conditions is driving innovation and growth in this industry. The polyimide coatings market is likely to grow significantly, especially in regions where the industry is strong and where there is a high level of R&D investment.

Europe

- Europe is focusing on innovation in polyimide coatings, with significant investments from companies like BASF and DuPont in R&D to enhance the thermal stability and chemical resistance of their products.

- The European Union's stringent regulations on chemical safety, such as REACH, are influencing manufacturers to adopt safer and more sustainable polyimide coating solutions, thereby reshaping the market landscape.

Asia Pacific

- The Asia-Pacific region is experiencing rapid industrialization, particularly in countries like China and India, which is driving the demand for polyimide coatings in electronics and automotive applications.

- Key players such as Kaneka Corporation and Mitsui Chemicals are expanding their production capacities in the region to meet the growing demand, supported by government initiatives promoting high-tech manufacturing.

Latin America

- Latin America is seeing a gradual increase in the adoption of polyimide coatings, particularly in Brazil and Mexico, where automotive manufacturing is on the rise, prompting local companies to seek advanced coating solutions.

- Government initiatives aimed at boosting local manufacturing capabilities are encouraging investments in polyimide coating technologies, with companies like PPG Industries expanding their operations in the region.

North America

- The North American market is witnessing a surge in demand for polyimide coatings due to the aerospace sector's growth, with companies like Boeing and Lockheed Martin investing in advanced materials for aircraft manufacturing.

- Recent regulatory changes aimed at reducing VOC emissions are pushing manufacturers to develop eco-friendly polyimide coatings, with organizations such as the EPA promoting sustainable practices in the coatings industry.

Middle East And Africa

- In the Middle East and Africa, the polyimide coatings market is being driven by the oil and gas sector, with companies like Saudi Aramco investing in advanced materials for pipeline protection.

- The region's unique climatic conditions necessitate the use of high-performance coatings, leading to increased interest from international manufacturers looking to establish a presence in this emerging market.

Did You Know?

“Polyimide coatings can withstand temperatures as high as 500 degrees Fahrenheit, making them ideal for applications in extreme environments such as aerospace and electronics.” — Polymer Science Journal

Segmental Market Size

The polyimide coatings market is growing steadily, driven by the growing demand from the aerospace, electronics, and automotive industries. The need for high-performance materials that can withstand extreme temperatures and harsh environments is driving the market. The need for more durable and energy-efficient coatings is also driving the market. DuPont and Kaneka are at the forefront of the market, with advanced formulations that meet these demands. Polyimide coatings are currently used in a wide range of applications, such as flexible printed circuit boards and high-temperature electrical insulation. North America and Asia-Pacific are the leading regions, with large-scale projects in the aerospace and electronics industries. In the transportation industry, the trend towards lightweight materials and the green economy is driving the market. Advances in polymerization and nanotechnology are driving the evolution of polyimide coatings, increasing their performance and application scope.

Future Outlook

Polyimide coatings will be in high demand from 2024 to 2032, with a CAGR of 5.82%. The increasing need for high-performance materials in the various industries, such as electronics, aeronautics, and automobiles, will drive this growth. The need for a longer-lasting product, more resistant to heat and more chemically resistant, is making polyimide coatings indispensable in the applications where they are used. In the electronics sector alone, the penetration of polyimide coatings could reach nearly 30% by 2032, as a result of the ongoing miniaturization of the components and the need for lightweight and efficient materials. Technological developments, such as the development of new formulations and new application methods, will also contribute to the growth of this market. Nanotechnology and the development of polyimide coatings with low migratory properties will respond to the increasing demand for sustainable materials. Also, the rise of electric vehicles and the development of new energy sources, in particular from renewable energies, will open up new opportunities for polyimide coatings, especially in terms of insulating and protective applications. Industry will continue to put performance and sustainability at the heart of its priorities, and the polyimide coatings market will evolve, becoming a strategic component of the future of advanced manufacturing.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 1.8 Billion |

| Market Size Value In 2023 | USD 1.92 Billion |

| Growth Rate | 6.70% (2023-2032) |

Polyimide Coatings Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.