Robotic End Effector Market Summary

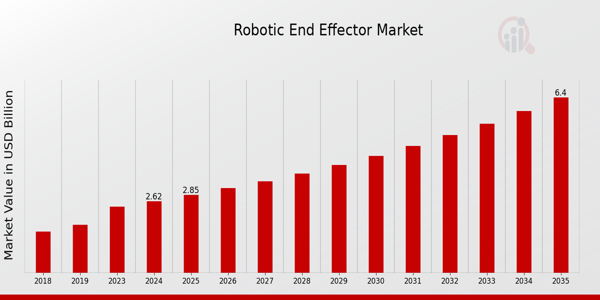

As per Market Research Future Analysis, the Robotic End Effector Market was valued at 2.42 USD Billion in 2023 and is projected to reach 6.4 USD Billion by 2035, growing at a CAGR of 8.46% from 2025 to 2035. The market is driven by increased automation in manufacturing, the rise of collaborative robots, and the expansion of e-commerce and logistics sectors. Key players are investing in R&D to innovate and meet diverse industrial needs, enhancing operational efficiencies across various applications.

Key Market Trends & Highlights

Significant trends are shaping the Robotic End Effector Market, driven by technological advancements and industry demands.

- The market is expected to grow from 2.62 USD Billion in 2024 to 6.4 USD Billion by 2035.

- Collaborative robots are growing at a rate of 15% annually, highlighting the demand for flexible automation.

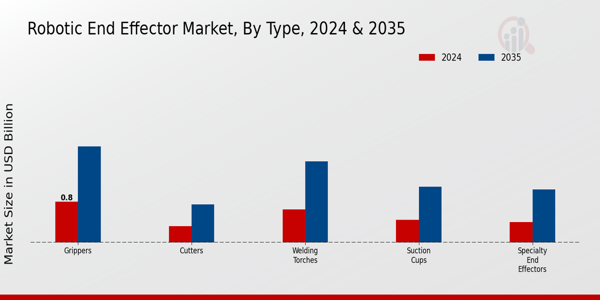

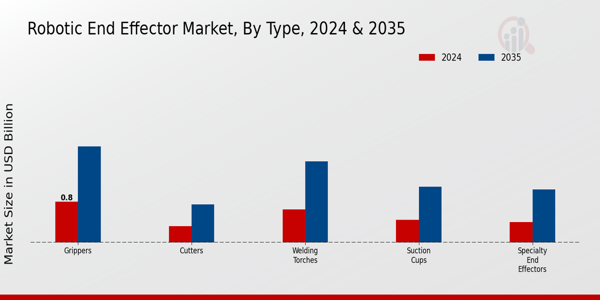

- Grippers are projected to achieve a valuation of 1.9 USD Billion by 2035, up from 0.8 USD Billion in 2024.

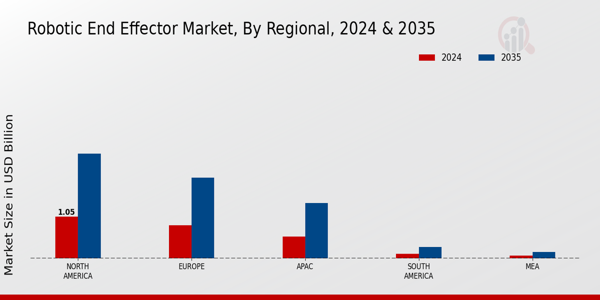

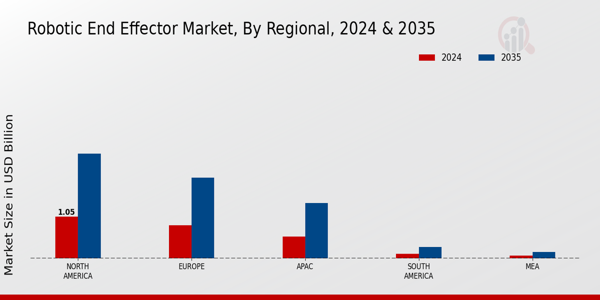

- North America is expected to lead the market, growing from 1.05 USD Billion in 2024 to 2.63 USD Billion by 2035.

Market Size & Forecast

2023 Market Size: USD 2.42 Billion

2024 Market Size: USD 2.62 Billion

2035 Market Size: USD 6.4 Billion

CAGR (2025-2035): 8.46%

Largest Regional Market Share in 2024: North America.

Major Players

Key companies include ABB, Yaskawa Electric, KUKA, Applied Robotics, Zimmer Group, Igus, FANUC, and Schmalz.

Key Robotic End Effector Market Trends Highlighted

The Robotic End Effector Market is currently experiencing significant shifts driven by various factors. One key market driver is the increasing demand for automation across industries, especially in manufacturing and logistics. Companies are looking to enhance efficiency, reduce operational costs, and improve precision in production processes, prompting the adoption of robotic technologies.

Additionally, advancements in artificial intelligence and machine learning are contributing to the evolution of robotic end effectors, enabling them to perform more complex tasks and adapt to different environments more effectively. Opportunities are emerging for businesses that invest in customizable end effectors tailored to specific industry needs.Customization lets robots do more things, which makes them useful in many fields, such as healthcare, food processing, and electronic assembly. There is also a chance for tech companies to work with businesses in different fields to make systems that use both hardware and software innovations.

Recent trends in the Robotic End Effector Market show that more and more people are using collaborative robots, or cobots, which are made to work with people.

This partnership makes the workplace safer and gives production lines more freedom. As more and more people care about the environment, manufacturers are looking for eco-friendly materials for robotic parts and trying to make systems that use less energy. Overall, the interplay of these trends and drivers is shaping the future landscape of the robotic end effector market on a global scale.

Source: Primary Research, Secondary Research, MRFR Database, and Analyst Review

Robotic End Effector Market Drivers

Increasing Automation in Various Industries

The trend of increasing automation across various industries represents a major driver for the Robotic End Effector Market. Industries such as automotive, electronics, and healthcare are progressively adopting automation technologies to enhance operational efficiency and reduce labor costs. According to the International Federation of Robotics, the number of industrial robots deployed globally has increased significantly over the last decade, with an average growth rate of around 10% annually.

This surge in robot adoption indicates a strong demand for robotic end effectors, which are crucial in enabling robots to perform complex, repetitive tasks. Established organizations like Fanuc Corporation and ABB Ltd are expanding their portfolios and investing heavily in smart technologies to meet this rising need for automation. Their efforts not only reflect a commitment to reducing manual labor but also fill the gap in market demand for advanced robotic solutions.

Technological Advancements in Robotics

Technological advancements in robotics, especially in artificial intelligence and machine learning, are facilitating the growth of the Robotic End Effector Market. Innovations in sensor technologies and control systems have greatly increased the capabilities and performance of robotic end effectors. For example, the development of dexterous grippers and intelligent end effectors that can adapt to various tasks demonstrates a significant leap forward.

According to industry reports, the investment in Research and Development (R&D) in the robotics sector has seen a year-on-year increase of approximately 15% over the past five years. Companies like KUKA have led projects that integrate smart technology with robotics solutions, showcasing how advancements are contributing to enhanced automation and efficiency across various applications.

Rising Demand for Customization in Manufacturing

The rising demand for customization in manufacturing processes is another key driver of the Robotic End Effector Market. As manufacturers aim to improve the flexibility of production lines to cater to diverse consumer preferences, the need for versatile robotic end effectors is surging. According to the Manufacturing Institute, nearly 70% of manufacturers reported increased requests for customized products in recent years. This trend necessitates the adaptation of manufacturing processes, requiring advanced robotic solutions capable of handling varied tasks seamlessly.

Companies such as Yaskawa Electric Corporation are actively developing customizable robotic end effectors that can easily be modified for different applications. This adaptability not only aids manufacturers in meeting consumer demands but also contributes to the overall growth of the market.

Robotic End Effector Market Segment Insights:

Robotic End Effector Market Type Insights

The Robotic End Effector Market is experiencing significant growth, primarily driven by advancements in automation and robotics across various industries. The market is broadly segmented into various types of end effectors, which include Grippers, Welding Torches, Suction Cups, Cutters, and Specialty End Effectors, each catering to different operational needs in manufacturing and logistics. In 2024, the Grippers segment is projected to be valued at 0.78 USD billion, demonstrating the majority holding within the market due to their versatility and widespread application in material handling and assembly processes.

Grippers are essential as they enable robots to grasp and manipulate objects efficiently, thereby boosting productivity levels in industrial settings. Following Grippers, Welding Torches are expected to reach a valuation of 0.64 USD billion in 2024. They play a significant role in the automotive and construction industries by facilitating efficient and precise welding operations, thereby enhancing the quality of completed products. The Suction Cups segment, valued at 0.52 USD billion in 2024, is crucial for handling delicate components without causing damage, especially in industries like electronics and packaging, where precision is paramount.

Cutters, with a market valuation of 0.44 USD billion, are utilized in various sectors for precise cutting applications, contributing to efficiency and cost reductions in manufacturing processes.

Lastly, Specialty End Effectors, valued at 0.24 USD Billion, address specific niche functions, allowing robots to perform specialized tasks that are not manageable with conventional end effectors. Each of these segments contributes to the overall market growth by enhancing operational efficiency and supporting the increasing demand for automation.

As companies continue to adopt robotic solutions for various applications, the Robotic End Effector Market is poised for notable expansion, with expected growth across all types of end effectors. The trends towards automation and Industry 4.0 drive innovation, allowing these segments to evolve and meet the challenging requirements of modern manufacturing and warehousing.

Factors such as increasing labor costs, demand for higher efficiency, and the need for accuracy in processes are key drivers of this transformation in the Robotic End Effector Market. Growth opportunities are prominent, particularly for Grippers and Welding Torches, as these segments dominate market revenue due to their integral roles in revolutionizing production cycles and improving operational workflows.

Source: Primary Research, Secondary Research, MRFR Database, and Analyst Review

Robotic End Effector Market Technology Insights

The Robotic End Effector Market, driven by advancements in Technology, is expected to witness significant growth, with a market valuation of 2.62 billion USD in 2024 and reaching 6.4 billion USD by 2035. The market is characterized by diverse technologies that play a crucial role in automating various industrial processes. Mechanical end effectors lead the market due to their versatility and robustness, making them essential in applications ranging from assembly to packaging.

Pneumatic systems are favored for their lightweight and energy-efficient operation, contributing significantly to the automation of repetitive tasks. Hydraulic end effectors, known for their high force capabilities, are widely utilized in heavy-duty applications, aiding in tasks that require considerable strength and precision. Electric end effectors, meanwhile, have been gaining traction for their precise control and adaptability in complex environments. With an expected CAGR of 8.46 percent from 2025 to 2035, the Robotic End Effector Market is set to expand, fueled by increased demand across sectors like manufacturing, logistics, and healthcare, while also addressing challenges such as integration and cost.

Robotic End Effector Market End Use Industry Insights

The Robotic End Effector Market demonstrates significant growth driven by diverse end use industries, contributing to a dynamic landscape. By 2024, the overall market is expected to be valued at 2.62 USD billion, highlighting the growing adoption of automation technology across various sectors. Within this market, the automotive industry plays a crucial role, utilizing robotic end effectors to enhance assembly line efficiency and improve manufacturing processes.

The electronics sector also thrives with the implementation of precision pick-and-place applications to meet high demand. Meanwhile, the aerospace industry benefits from advanced robotics in assembling complex components, ensuring increased reliability and safety in operations. The food and beverage industry utilizes robotic end effectors for packaging automation and handling, improving production efficiency while maintaining product quality.

The Robotic End Effector Market statistics reveal that these industries not only drive considerable market growth but also reflect a broader trend towards automation in global manufacturing processes. As industries increasingly invest in automation, opportunities for innovation and technological advancements proliferate, foreshadowing a robust market evolution in the forthcoming years.

Robotic End Effector Market Payload Capacity Insights

The Robotic End Effector Market, particularly focusing on the Payload Capacity segment, is experiencing significant growth, driven by increasing automation across various industries. By 2024, the market is projected to achieve a valuation of 2.62 billion USD, highlighting its expanding relevance in manufacturing and logistics.

The segmentation of payload capacity into Lightweight, Medium Weight, and Heavyweight categories provides clarity on specific applications and efficiencies. Lightweight end effectors are particularly important for delicate tasks and precision handling, catering to sectors such as electronics and pharmaceuticals. In contrast, Medium Weight and Heavyweight end effectors play crucial roles in heavy manufacturing and construction, allowing for enhanced productivity and operational efficiency.

The importance of these categories is underscored by the increasing demand for robotics that can handle various payloads effectively, ultimately driving market growth. Furthermore, rising labor costs and the need for improved workplace safety offer substantial opportunities for the Robotic End Effector Market, while challenges like high initial investment can impact adoption rates.

Overall, the Robotic End Effector Market data reflects robust trends emphasizing flexibility and efficiency across various payload capacities in a dynamic industrial landscape.

Robotic End Effector Market Regional Insights

The Robotic End Effector Market has shown promising growth across various regional divisions, with a collective valuation anticipated to reach 2.62 USD Billion in 2024. North America stands out with a valuation of 1.1 USD Billion in 2024, representing a majority holding within the market, driven by significant investments in automation and a strong manufacturing base.

Europe follows with a valuation of 0.85 USD billion, where advancements in technology and a focus on Research and Development are fostering market expansion. South America, while smaller at 0.25 USD billion, shows potential for growth due to the increasing adoption of automation in industries like agriculture. The Asia Pacific region, valued at 0.32 USD billion, is expanding rapidly, reflecting a growing industrial base and government initiatives to promote robotics.

Lastly, the Middle East and Africa are at 0.1 USD billion, where efforts are being made to modernize industries, albeit slower than other regions. Overall, the Robotic End Effector Market segmentation reveals a diverse landscape with different regional dynamics influencing growth opportunities and challenges across these markets.

Source: Primary Research, Secondary Research, MRFR Database, and Analyst Review

Robotic End Effector Market Key Players and Competitive Insights:

The Robotic End Effector Market is characterized by a dynamic landscape, driven by advancements in automation, machine learning, and industrial robotics. Companies are increasingly focusing on enhancing their product offerings to meet the diverse needs of various industries, including manufacturing, logistics, and assembly.

As competition intensifies, businesses are investing in research and development to innovate their robotic end effectors, which are crucial for tasks such as gripping, manipulation, and picking. The market is influenced by the rapid adoption of robotics in industries seeking efficiency and precision. This competitive environment calls for continuous improvements in functionality and versatility to cater to specific applications, leading to an array of products that cater to various operational needs.

ABB has established a strong foothold in the Robotic End Effector Market through its commitment to quality and innovation. With a focus on developing cutting-edge robotic solutions, ABB offers a diverse range of end effectors that are designed to improve productivity and operational efficiency across multiple sectors. The company's strength lies in its comprehensive expertise in automation and robotics, which allows it to integrate advanced technologies into its products.

ABB's significant market presence is bolstered by its extensive global network and partnerships, ensuring that its robotic solutions are accessible to a wide audience. The company’s ongoing investments in R&D enable it to continuously enhance its offerings, making it a formidable player in the competitive landscape of the robotic end effector market.

Destaco is recognized for its innovative approach in the Robotic End Effector Market, where it offers a wide array of end effectors, including grippers and tooling systems, tailored for various applications. The company has built a reputation for delivering high-quality, durable products that meet the rigorous demands of automation in different industries.

Destaco's market presence is strengthened by its commitment to customer satisfaction and its ability to provide customized solutions that cater to the unique requirements of clients. Additionally, Destaco engages in strategic mergers and acquisitions to expand its product portfolio and increase its market share globally. This strategy not only enhances their technological capabilities but also positions them as a leader in the sector, allowing them to effectively compete with other established players in the Robotic End Effector Market.

Key Companies in the Robotic End Effector Market Include:

-

ABB

-

Destaco

-

KUKA

-

Piab

-

Robot System Products

-

Endo Robotics

-

Applied Robotics

-

SCHUNK

-

MOTOMAN

-

FANUC

-

Universal Robots

-

Staubli

-

Gimatic

-

Zimmer Group

Robotic End Effector Market Industry Developments

-

Q2 2024: OnRobot Launches New D:PLOY Palletizing Solution to Automate End-of-Line Tasks OnRobot announced the launch of its D:PLOY Palletizing solution, a new robotic end-effector system designed to automate end-of-line palletizing tasks for manufacturers, aiming to reduce deployment time and complexity.

-

Q2 2024: Zimmer Group Expands U.S. Operations with New North American Headquarters Zimmer Group, a leading provider of robotic end-effectors, opened a new North American headquarters in Cincinnati, Ohio, to support growing demand for its automation and end-of-arm tooling solutions.

-

Q1 2024: SCHUNK Introduces New EGH Co-act Gripper for Collaborative Robots SCHUNK launched the EGH Co-act Gripper, a new electric gripper designed for collaborative robots, expanding its portfolio of robotic end-effectors for flexible automation in small parts handling.

-

Q2 2024: Piab Acquires Joulin to Strengthen Robotic Gripping Solutions Piab, a global leader in industrial automation, acquired Joulin, a specialist in vacuum gripping systems, to expand its robotic end-effector offerings for the packaging and logistics sectors.

-

Q1 2024: Robotiq Launches PowerPick, a Heavy-Duty Vacuum Gripper for Industrial Robots Robotiq introduced PowerPick, a new vacuum gripper designed for heavy-duty industrial applications, enabling robots to handle larger and heavier items in manufacturing and logistics.

-

Q2 2024: ABB Opens New Robotics Mega Factory in Shanghai ABB inaugurated a new robotics mega factory in Shanghai, which will produce advanced robotic arms and end-effectors to meet rising demand in Asia’s manufacturing and logistics sectors.

-

Q1 2024: Soft Robotics Raises $23 Million in Series C Funding to Expand Food Automation Solutions Soft Robotics secured $23 million in Series C funding to accelerate the development and commercialization of its robotic end-effectors for food handling and packaging automation.

-

Q2 2024: DESTACO Launches New Line of Lightweight End-Effector Tooling for Automotive Industry DESTACO unveiled a new line of lightweight end-effector tooling designed to improve efficiency and flexibility in automotive manufacturing and assembly lines.

-

Q1 2024: KUKA and Schmalz Announce Strategic Partnership for Smart Gripping Solutions KUKA and Schmalz entered a strategic partnership to jointly develop smart robotic gripping solutions, integrating advanced sensors and AI for improved automation performance.

-

Q2 2024: Fanuc Unveils New Collaborative Robot with Enhanced End-Effector Capabilities Fanuc launched a new collaborative robot featuring advanced end-effector compatibility, targeting flexible automation in electronics and consumer goods manufacturing.

-

Q1 2024: ATI Industrial Automation Releases New QC-11 Robotic Tool Changer ATI Industrial Automation introduced the QC-11, a new robotic tool changer designed to enable fast and reliable switching of end-effectors in high-mix manufacturing environments.

-

Q2 2024: Universal Robots and Robotiq Partner to Deliver Plug-and-Play Palletizing Solution Universal Robots and Robotiq announced a partnership to offer a plug-and-play palletizing solution, combining collaborative robots with advanced end-effectors for streamlined warehouse automation.

Robotic End Effector Market Segmentation Insights

-

Robotic End Effector Market Type Outlook

-

Grippers

-

Welding Torches

-

Suction Cups

-

Cutters

-

Specialty End Effectors

-

Robotic End Effector Market Technology Outlook

-

Mechanical

-

Pneumatic

-

Hydraulic

-

Electric

-

Robotic End Effector Market End Use Industry Outlook

-

Automotive

-

Electronics

-

Aerospace

-

Food and Beverage

-

Robotic End Effector Market Payload Capacity Outlook

-

Lightweight

-

Medium Weight

-

Heavyweight

-

Robotic End Effector Market Regional Outlook

-

North America

-

Europe

-

South America

-

Asia Pacific

-

Middle East and Africa

Robotic End Effector Market Report Scope

|

Report Attribute/Metric

|

Details

|

|

Market Size 2023

|

2.42 (USD Billion)

|

|

Market Size 2024

|

2.62 (USD Billion)

|

|

Market Size 2035

|

6.4 (USD Billion)

|

|

Compound Annual Growth Rate (CAGR)

|

8.46% (2025 - 2035)

|

|

Report Coverage

|

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends

|

|

Base Year

|

2024

|

|

Market Forecast Period

|

2025 - 2035

|

|

Historical Data

|

2019 - 2024

|

|

Market Forecast Units

|

USD Billion

|

|

Key Companies Profiled

|

ABB, Destaco, KUKA, Piab, Ingersoll Rand, Robot System Products, Endo Robotics, Applied Robotics, SCHUNK, MOTOMAN, FANUC, Universal Robots, Staubli, Gimatic, Zimmer Group

|

|

Segments Covered

|

Type, Technology, End Use Industry, Payload Capacity, Regional

|

|

Key Market Opportunities

|

Increased automation demand, Advanced AI integration, Customizable end effector solutions, Growth in e-commerce logistics, Expansion in healthcare robotics

|

|

Key Market Dynamics

|

Increasing automation demand, Technological advancements, Cost reduction strategies, growing research and development, and rising labor shortages

|

|

Countries Covered

|

North America, Europe, APAC, South America, MEA

|

Frequently Asked Questions (FAQ):

The Robotic End Effector Market is expected to reach a valuation of 6.4 USD billion by 2035.

The market is anticipated to grow at a CAGR of 8.46% from 2025 to 2035.

North America is expected to dominate the market with a valuation of 2.65 USD billion in 2035.

Grippers are projected to be valued at 1.89 USD billion in the market by 2035.

Major players include ABB, KUKA, and FANUC, among others.

The market value for Suction Cups is projected to be 0.52 USD billion in 2024.

Asia Pacific is expected to experience significant growth and reach 0.8 USD billion by 2035.

Welding Torches are forecasted to achieve a market size of 1.57 USD billion by 2035.

By 2035, the Specialty End Effectors segment is expected to be valued at 0.62 USD billion.

The market faces challenges such as competition and rapid technological advancements, impacting growth.