- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

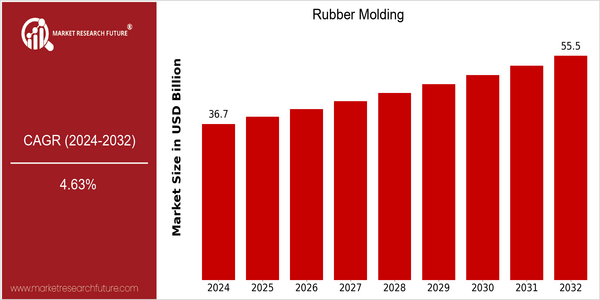

| Year | Value |

|---|---|

| 2024 | USD 36.7 Billion |

| 2032 | USD 55.5 Billion |

| CAGR (2024-2032) | 4.63 % |

Note – Market size depicts the revenue generated over the financial year

The global rubber injection molding market is expected to grow significantly, from 36.7 billion in 2024 to 55.5 billion in 2032. The compound annual growth rate (CAGR) of this market is 4.6%. The demand for rubber injection molded products in various industries, such as the automobile, aeronautics and the consumer goods industry, is driving the market. In addition, as manufacturers are increasingly looking for ways to improve product performance and longevity, they are increasingly turning to injection and compression molding. , which also drives the market. Moreover, the major rubber injection molding companies such as Continental AG, Bridgestone, and Goodyear Tire & Rubber Company are investing in research and development and strategic alliances to strengthen their market position. The recent alliances, such as the development of sustainable rubber materials and the improvement of rubber production efficiency, are a sign of the industry's trend towards green practices. In addition, the increasing popularity of electric vehicles and the increasing demand for lightweight materials will also bring new opportunities for rubber injection molding, and the prospects for the market will be better.

Regional Market Size

Regional Deep Dive

The rubber molding market is characterized by a wide range of applications across industries, such as automobile, aerospace, and consumer goods. Each region has its own dynamic characteristics, which are influenced by the production environment, government policies, and economic conditions. The rubber molding market is expected to grow, driven by the high-performance rubber products and molding equipment, and the continuous improvement of rubber molding technology. In addition, the trend of green consumption has driven the development of rubber molding materials and green molding processes.

Europe

- Europe is aiming for a circular economy. Many rubber manufacturers are adopting the principles of the circular economy. For example, Continental and Michelin are investing in the technology for reclaiming rubber from used tyres. This will have a significant impact on the supply chain.

- The European Union's stringent regulations on chemical safety, such as REACH, are compelling rubber manufacturers to innovate and reformulate their products, leading to the development of safer and more environmentally friendly rubber materials.

Asia Pacific

- The rubber industry is flourishing in the East, especially in China and India. The leading firms, such as Bridgestone and Yokohama, are increasing their manufacturing activities in these countries.

- Technological advancements in molding processes, such as 3D printing and automation, are gaining traction in Asia-Pacific, enabling manufacturers to produce complex rubber components more efficiently and at lower costs.

Latin America

- Latin America is seeing a shift towards local production of rubber molded products, driven by the need to reduce import dependency. Companies like Pirelli are establishing manufacturing plants in Brazil to cater to the growing local market.

- Government initiatives aimed at boosting local manufacturing and reducing tariffs on raw materials are encouraging investments in the rubber molding sector, which is expected to enhance the competitiveness of local manufacturers.

North America

- In North America the demand for light-weight materials is growing, especially in the automobile industry, in order to improve fuel economy and reduce emissions. To meet this demand, rubber companies such as Continental and Goodyear are investing in new rubber compounds.

- In the United States, recent changes in the standards for exhaust gas regulation are forcing automobile manufacturers to adopt more and more sophisticated rubber components. This has led to closer collaboration between rubber molders and automobile manufacturers to develop products that meet these standards.

Middle East And Africa

- The rubber moulding market in Africa and the Middle East is influenced by the growth in the construction industry, especially in the Gulf Cooperation Council countries, where a large number of construction projects are under way. Al-Futtaim and Al-Naboodah are the main companies in this market.

- The region's unique climatic conditions are prompting the development of specialized rubber products that can withstand extreme temperatures, leading to innovations in material science and product design.

Did You Know?

“Did you know that approximately 70% of the rubber used in the automotive industry is molded into various components, highlighting the critical role of rubber molding in vehicle manufacturing?” — Automotive Rubber Molding Association

Segmental Market Size

The rubber moulding market is currently undergoing a steady period of growth, driven by the increasing demand for rubber components from industries such as the automotive, aeronautical, and consumer goods sectors. The key growth drivers are the rising need for durable and flexible materials, the development of manufacturing processes, and the tightening of regulatory standards promoting safety and quality. The industry leaders are Continental AG and Goodyear, which are making use of the latest moulding techniques to enhance the performance and the sustainability of their products. The rubber moulding technology is currently at a stage of maturity, with widespread implementation in North America and Europe. Its key applications are seals, gaskets, and vibration dampers for the automobile industry, which are essential for vehicle performance and safety. The key trends are the drive for sustainable materials and the integration of smart technology into manufacturing processes. Injection moulding and compression moulding are also evolving, with the automation of processes and the integration of precision engineering to meet the growing demand for efficiency and quality.

Future Outlook

The rubber molding market will be expected to grow significantly from 2024 to 2032, with an estimated increase from $36.7 billion to $55.5 billion, with a compound annual growth rate (CAGR) of 4.3 percent. This growth is due to the rising demand for rubber molding products in various industries, such as the automobile industry, the aeronautical industry, and the consumer goods industry. And the growing importance of light, durable materials in the production of products. The adoption of rubber molding is expected to increase as a result, thereby improving product performance and long-term viability. The penetration rate of rubber molding components in the automobile industry alone is expected to be about 30 percent by 2032, mainly due to the development of electric vehicle technology and the need for high-performance parts. In addition, the introduction of automation and smart manufacturing will transform the rubber molding industry. Moreover, innovations in materials science, such as the development of eco-friendly and high-performance elastomers, will also accelerate the growth of the market. And regulations to reduce the carbon footprint of products and promote sustainable manufacturing will also promote the use of rubber molding. The use of 3D printing in mold design and manufacturing will also play an important role in the future of the market, enabling faster prototyping and more customization. In summary, the rubber molding industry is expected to be able to develop at a fast pace in the future, driven by technological developments and changes in customer needs.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2023 | USD 36.70 Billion |

| Growth Rate | 4.63% (2024-2032) |

Rubber Molding Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.