Global Splicing Tapes Market Overview

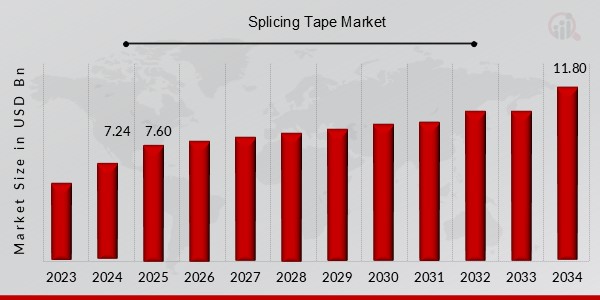

The Splicing Tapes Market Size Was Valued at USD 601.09 Million In 2024. The Splicing Tapes Industry Is Projected to Grow from USD 611.52 Million In 2025 To USD 796.17 Million By 2035, Exhibiting A Compound Annual Growth Rate (CAGR) Of 2.6 % During the Forecast Period (2025-2035).

Growing Demand in Electronics Packaging and Expansion of E-commerce Business and Driver impact Analysis and Compliance Are Driving the Growth of the Splicing Tapes Market.

As Per Analyst At MRFR, “The splicing tapes market is highly dependent on end-user industries such as paper & printing, packaging, automotive, electronics, and construction. Fluctuations in demand within these industries pose a significant restraint on market growth. For instance, the global paper and printing industry has experienced a consistent decline due to the shift toward digital media. This trend has reduced the need for splicing tapes used in paper production and printing processes. Similarly, the packaging industry, a major consumer of splicing tapes, faces fluctuating demand influenced by global economic conditions and consumer preferences.”

FIGURE 1: SPLICING TAPES MARKET VALUE (2019-2035) USD MILLION

Source: Secondary Research, Primary Research, MRFR Database, And Analyst Review

Splicing Tapes Market Opportunity

-

Emergence of Smart Packaging Solutions

The rapid adoption of smart packaging solutions is reshaping industries globally, creating significant growth opportunities for the splicing tapes market. Smart packaging integrates advanced technologies such as sensors, RFID tags, and QR codes to enhance functionality, offering benefits like real-time tracking, extended shelf life, and improved consumer engagement. This trend is particularly prominent in sectors such as food & beverages, pharmaceuticals, and logistics. Splicing tapes, known for their durability, high-temperature resistance, and strong adhesive properties, play a crucial role in the manufacturing and processing phases of smart packaging materials.

The demand for tapes with specialized features—such as heat resistance, solvent resistance, and compatibility with diverse substrates like polyethylene and polyester—is rising to meet the complex requirements of high-speed production lines involved in smart packaging. For instance, the food industry is leveraging smart packaging for freshness indicators, where splicing tapes are essential for ensuring seamless transitions in the continuous production of packaging materials. Similarly, in the pharmaceutical sector, RFID-enabled smart packaging for drug traceability requires precise and reliable splicing tapes to maintain production efficiency and quality standards.

Many companies are already innovating in high-performance splicing tapes tailored for smart packaging applications. As the global push toward sustainability and digitalization accelerates, the role of splicing tapes in enabling cutting-edge smart packaging solutions is set to expand.

Splicing Tapes Market Segment Insights

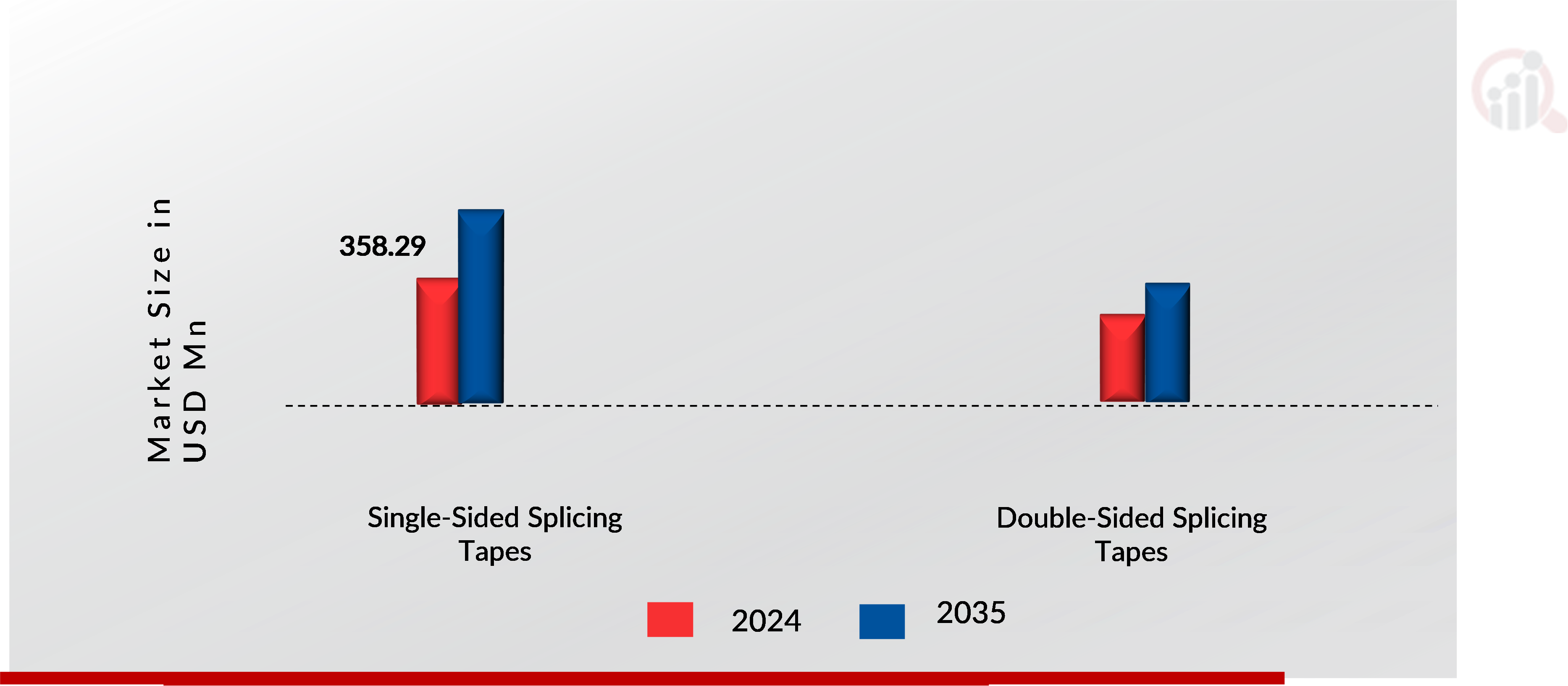

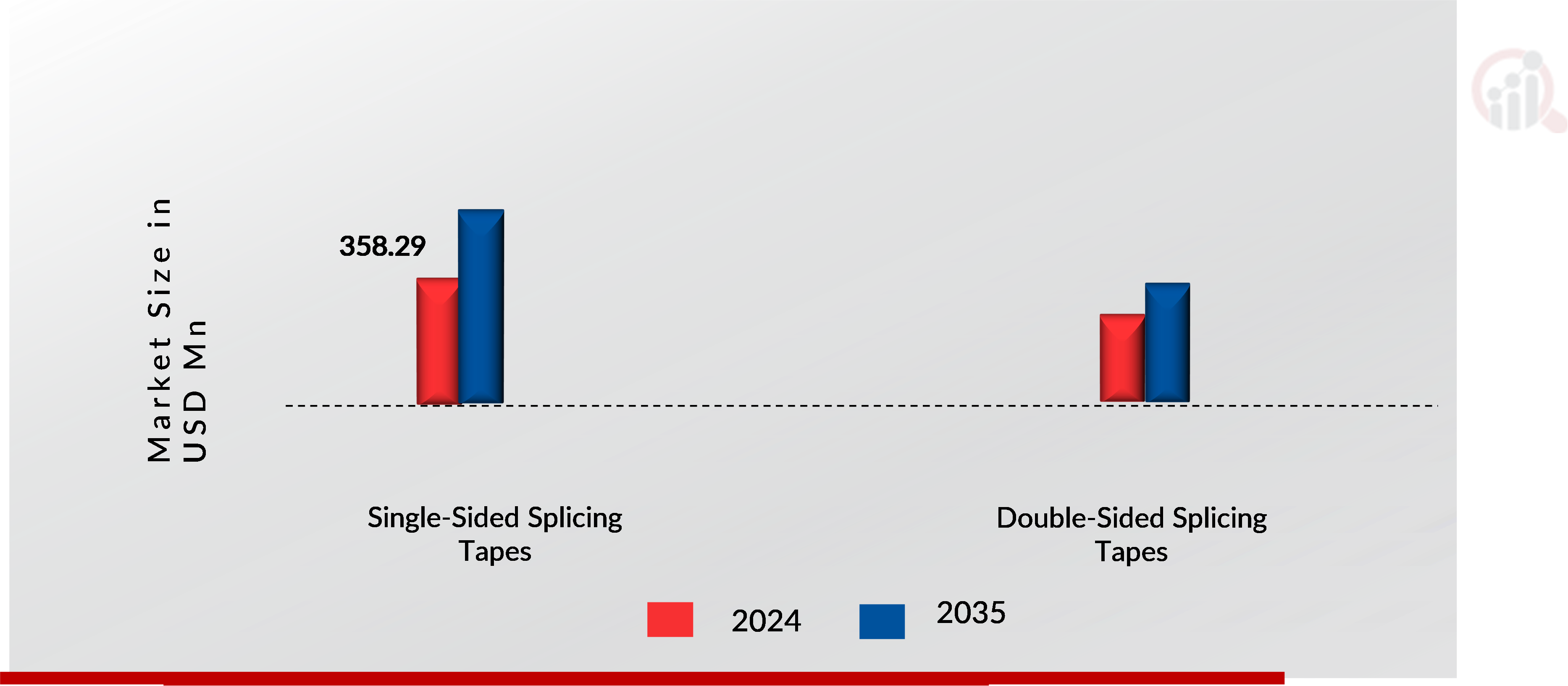

Splicing Tapes by Type Insights

Based on type, the Splicing Tapes Market is segmented into: Single-Sided Splicing Tapes

And Double-Sided Splicing Tapes. The Single-Sided Splicing Tapes segment dominated the global market in 2023, while the Double-Sided Splicing Tapes is projected to be the fastest–growing segment during the forecast period. Single-sided splicing tapes are adhesives that have been developed for use in easy and efficient bonding applications in different industrial applications. These have an adhesive only on one side, and the other side has no adhesive. Therefore, they are perfect for splicing paper, films, and other substrates during printing, packaging, or converting.

Single-sided splicing tapes are known to have very high strength and reliability, ensuring that the splice will stay intact under difficult conditions like high-speed machines, high temperatures, or solvents.

Backing materials are typically made out of paper, polyester, or polypropylene, which offer good tensile strength and excellent conformability to the user. Key advantages of single-sided splicing tape include its straightforward and uncomplicated use. These need to be applied only on one side and hence require no intricate equipment or procedures, which makes it even easier. These tapes are commonly used in web processing industries, where constant production and less downtime are required.

There are a wide range of temperature-resistive, UV-stable, and adhesive-compatible splicing tape solutions available in the market. Their role in reducing waste and enhancing operational efficiency makes them indispensable in industries such as automotive, textiles, and electronics, where precision and durability are paramount.

Figure 2: Splicing Tapes Market Share by Type 2024 And 2035 (USD Million)

Source: Secondary Research, Primary Research, Market Research Future Database and Analyst Review

Splicing Tapes by Material Insights

Based on material, the Splicing Tapes Market is segmented into: Paper-Based Splicing Tapes, Scalability, Plastic-Based Splicing Tapes, Foam-Based Splicing Tapes, Others. The Plastic-Based Splicing Tapes segment dominated the global market in 2023, while the Foam-Based Splicing Tapes is projected to be the fastest–growing segment during the forecast period. In industrial settings where cost-effective, environmentally friendly, and lightweight splicing solutions are needed, paper-based splicing tapes are frequently utilized. These tapes can firmly join materials like paper, films, and fabrics because they are composed of high-strength paper that has an adhesive coating on one or both sides.

Paper-based splicing tapes, which are often used in printing, packing, and conversion, provide exceptional adherence even in high-speed applications.

Their biodegradability makes them popular and fits perfectly with the emerging trend of sustainability. Compatibility with printing processes is one of the characteristics of paper-based splicing tapes. Because they are readily ripped by hand, they may be used quickly throughout production. These tapes are also resistant to heat and solvents, which guarantees their longevity in harsh settings. They are adaptable to a range of industrial needs because of the paper backing's great conformability, which guarantees a strong binding on uneven surfaces.

To satisfy certain operating requirements, such as strong tack, low residue, or UV resistance, manufacturers frequently provide these tapes in a variety of adhesive formulas. Because paper-based splicing tapes are recyclable and biodegradable, they not only increase operational efficiency but also promote environmental responsibility. They are a popular option in applications where performance and sustainability are given equal weight because of their dependability and affordability.

Splicing Tapes by Adhesive Type Insights

Based on Adhesive Type, the Splicing Tapes Market is segmented into: Acrylic, Rubber, Silicone and Others. The Rubber segment dominated the global market in 2023, while the Acrylic is projected to be the fastest–growing segment during the forecast period. Acrylic Adhesive is a type of synthetic adhesive made from acrylic polymers, known for its strong bonding properties, versatility, and long-lasting performance. These adhesives are widely used in a variety of industries due to their ability to provide reliable and durable bonds across many materials, including metals, plastics, glass, and paper.

Acrylic adhesives are particularly valued for their resistance to environmental factors such as UV light, moisture, and temperature fluctuations, making them ideal for both indoor and outdoor applications.

Acrylic adhesives are frequently used in film splicing, particularly in the motion picture and photographic industries. They provide a strong, permanent bond that securely joins film strips without damaging or degrading the original material. These adhesives are ideal for archival work and film restoration because they do not yellow over time, preserving the clarity and appearance of the film. In packaging, acrylic adhesive splicing tapes are used to bond materials in processes such as sealing, labeling, or packing fragile items.

The adhesive’s resistance to environmental changes makes it suitable for packaging applications that require the tape to hold up under varying conditions, including temperature extremes and exposure to UV light.

As concerns for material preservation and environmental resistance rise, the use of acrylic adhesives continues to grow. Acrylic adhesives are highly valued for their resistance to yellowing and degradation over time, ensuring that spliced materials like films and magnetic tapes maintain their original quality. This is especially important for archival and restoration projects, where the integrity of the material must be preserved. As the growing demand for non-intrusive, stable, and long-lasting bonds continues, acrylic adhesives are becoming the preferred choice for splicing tapes in various industries.

Splicing Tapes By Application Insights

Based on applications, the Splicing Tapes Market is segmented into: Printing Industry , Paper & Pulp Industry, Film & Foil Processing, Packaging Industry, Textile Industry, and Others. The Printing Industry segment dominated the global market in 2023, while the Textile Industry is projected to be the fastest–growing segment during the forecast period. In the printing industry, splicing tapes are essential tools that facilitate the seamless joining of material rolls, ensuring uninterrupted production processes. Splicing tape is used in the printing industry to join materials like paper, film, and corrugated board to create a longer printing surface.

Splicing tapes are also used for tabbing and closing rolls of printing substrate. The primary uses of splicing tapes in this sector include offset printing, flexographic printing, and rotogravure printing. By allowing for quick roll changes without stopping the press, splicing tapes minimize downtime and enhance overall productivity. In offset printing, splicing tapes help maintain uninterrupted paper flow between printing machines. They join paper rolls together quickly and securely, allowing for continuous printing. Similarly, in flexographic printing, tapes ensure seamless material feeding in high-speed presses.

Rotogravure printing also benefits from these tapes, as they are used to connect large rolls of material, enabling the printing process to run smoothly. The technological advancements in printing, which require faster and more reliable processes, have made splicing tapes a critical component in the modern printing workflow. The demand for better print quality, shorter lead times, and increased cost-efficiency also contributes to the growing usage of splicing tapes in the printing industry. As digitalization and e-commerce continue to rise, there is a growing need for flexible packaging solutions that can be produced quickly and efficiently.

Splicing tapes help meet this demand by enabling continuous operation, which is crucial in high-speed printing environments.

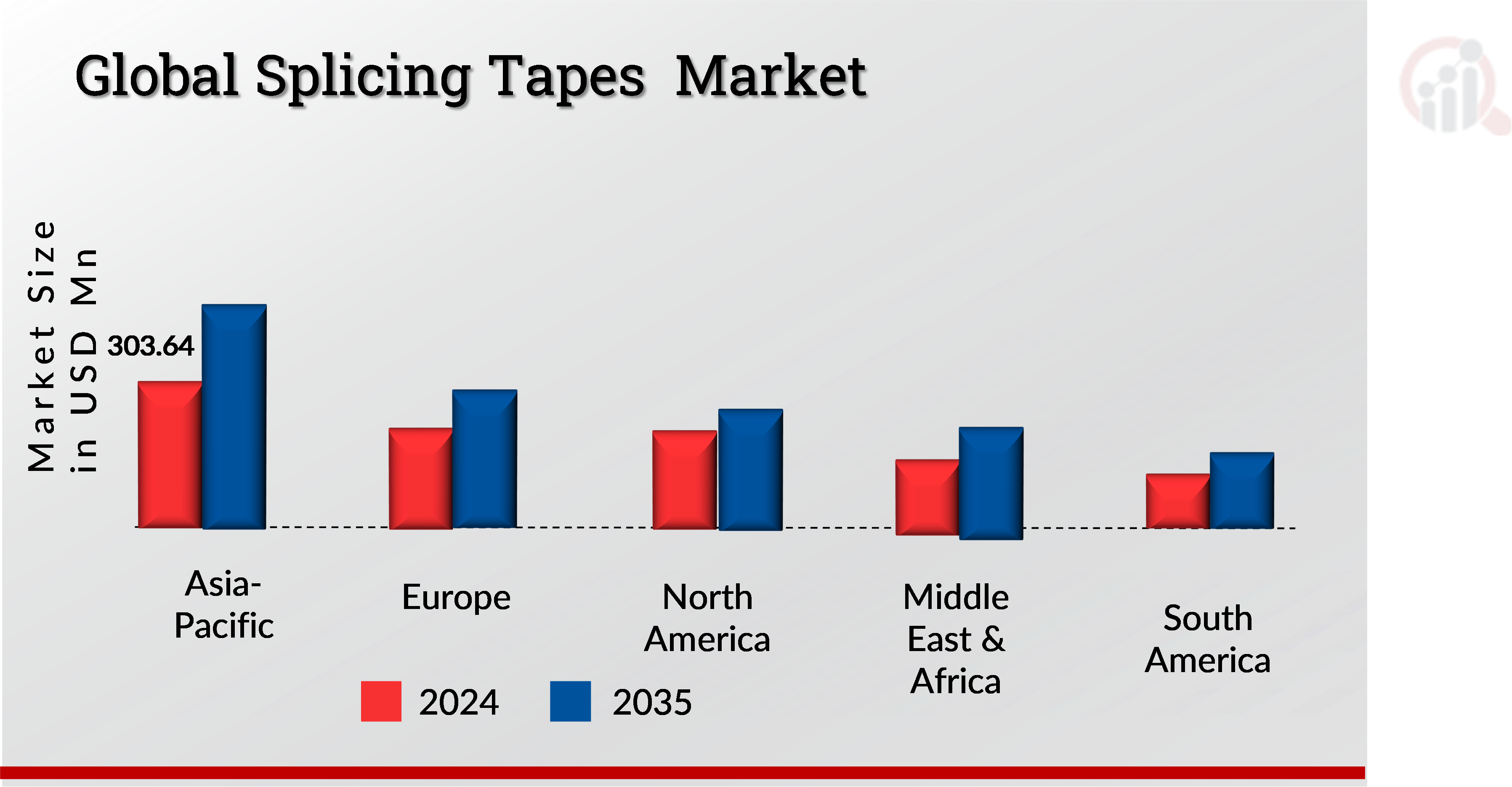

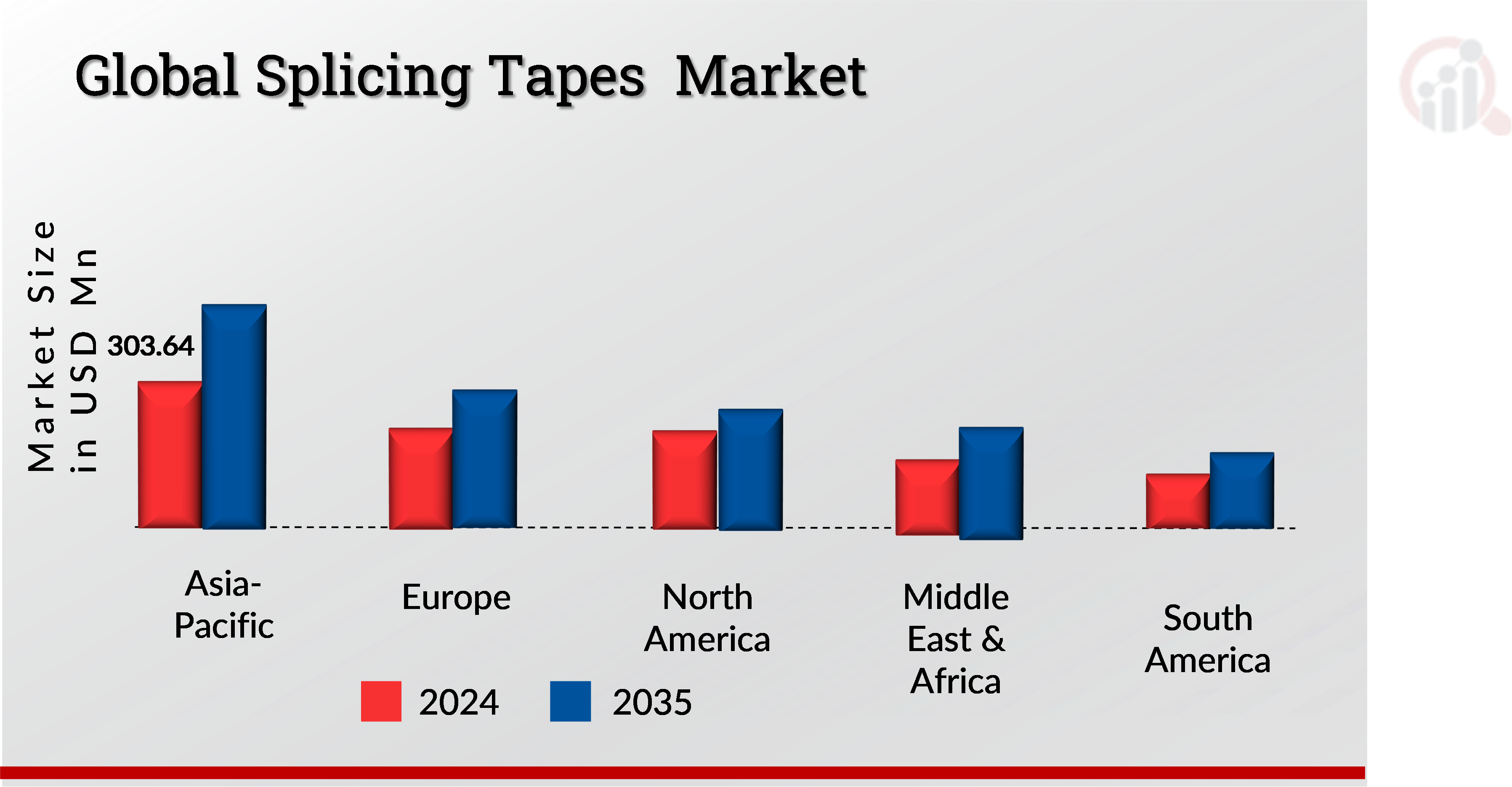

Splicing Tapes Regional Insights

By Region, The Study Provides Market Insights into North America, Europe, Asia-Pacific and Rest of the World. The North America Splicing Tape Market is expected to grow owing to the rising demand throughout the industries that include paper, printing, packaging, as well as electronics. It commonly finds its place in the splicing tapes, these sorts of tapes are quite important for the joints made between materials that can withstand high tensile strength, can be temperature resistant, and have superior adhesion, making it essential in high-speed production lines.

Major players in the industry are therefore channeling their efforts into research and development towards making sustainable and highly efficient products that should match up with changing trends in the consumer and industrial worlds. The U.S. dominated the market owing to the established industrial base along with technological advancements in the country. Canada is expected to grow owing to the increasing printing and packaging industries. Whereas challenges like the fluctuating raw material prices along with stringent environmental regulations can hamper the growth of the market.

However, the rising innovation and the adoption of the automation in the manufacturing processes are expected to cater to such concerns.

The South America Splicing Tape Market is expected to grow at a significant rate due to the increasing manufacturing facilities in the region and its expanding demand in various end-user industries such as paper, packaging, and printing. Some key countries which see a major focus to their well-established industrial bases and infrastructures at this stage of market growth include Brazil, Mexico, Argentina, and Chile.

Also, splicing tapes account for an important factor that allows the production of the industry, especially where Brazil becomes the greatest global exporter of paper and pulp since they utilize splicing tapes to control or manage production outages.

Meanwhile, just as in the packaging, which is being dominated by growing e-commerce levels and demand for consumer goods in the region, there is also the increase in splicing tapes which enable seamless joining and continuous production during the complete production cycle. Technological advancements along with the high-performance splicing tapes possessing thermal resistance, durability and chemical stability, their other applications have extended into specialized industries such as electronics and automobile industries. The developing automotive manufacturing industry of Mexico, for instance, employs splicing tapes under varied assembly and bonding applications.

Besides, there is increasing demand for splicing tapes due to an increased requirement of the printing sector for quality packaging and advertising media. It is increasingly evident with the introduction of the environmental sustainability factor that manufacturers within the region are focusing on producing eco-splicing tape that complies with global environmental standards. Nevertheless, several challenges will be hindrances to market growth, such as the economic market volatility, incessantly changing raw material prices, and foreign product competition.

Europe Splicing Tape Market is expected to have steady growth as it is further complemented by technological advancement in industrial manufacturing and the growing importance for efficient production processes. Splicing tapes are known to bring about smooth processes, especially in the well-established industries in the region, including those that engage in the manufacturing of paper, packaging, printing, and electronics. The industry that is dominant in the paper and pulp sectors, with Finland, Sweden, and Germany being leaders, has its operations largely based on splicing tapes to maintain continuous production.

This means that the packaging division brings in a significant contribution to market expansion that is basically driven by the increasing penetration of e-commerce and demand for sustainable packaging solutions.

Figure 3: Splicing Tapes Market Value by Region 2024 And 2035 (USD Million)

Source: Secondary Research, Primary Research, Market Research Future Database, And Analyst Review

Further, The Countries Considered In The Scope Of The Splicing Tapes Market Are The Us, Canada, Mexico, Uk, Germany, France, Italy, Spain, Switzerland, Austria, Belgium, Denmark, Finland, Greece, Hungary, Italy, Luxembourg, Netherlands, Norway, Poland, Portugal, Slovakia, Sweden, Romania, Ireland, China, Japan, Singapore, Malaysia, Indonesia, Philippines, South Korea, Hong Kong, Macau, Singapore, Brunei, India, Australia & New Zealand, South Africa, Egypt, Nigeria, Saudi Arabia, Qatar, United Arab Emirates, Bahrain, Kuwait, And Oman, Brazil, Argentina, Chile, And Others.

Splicing Tapes Key Market Players & Competitive Insights

Major Market Players Are Spending a Lot of Money On R&D To Increase Their Product Lines, Which Will Help the Splicing Tapes Market Grow Even More. Market Participants Are Also Taking a Range of Strategic Initiatives to Grow Their Footprint Globally, With Key Market Developments Such as New Product Launches, Contractual Agreements, Mergers and Acquisitions, Increased Investments, And Collaboration with Other Organizations. Competitors In the Splicing Tapes Industry Must Offer Cost-Effective Items to Expand and Survive in An Increasingly Competitive and Rising Market Environment.

In The Competitive Splicing Tapes Industry, Companies Are Driving Innovation by Developing Integrated Splicing Tapes Solutions with Strong Compatibility and Scalable Connectivity Options. According To MRFR Analysis, The Key Players in the Splicing Tapes Sector Include 3M, AVERY DENNISON CORPORATION, Nitto Denko Corporation, Tesa SE, Scapa Group PLC, IPG (Intertape polymer group), Shurtape Technologies, LLC, ORAFOL, Adhesives Research, Inc., ECHO tape.

Key Companies in the Splicing Tapes Market Include

- AVERY DENNISON CORPORATION

- IPG (Intertape polymer group)

- Shurtape Technologies, LLC

Splicing Tapes Market Industry Developments

February 2024: Nitto Denko in partnership with researchers from Kyushu University, developed a user-friendly tape capable of effortlessly adhering 2D materials to various surfaces, simplifying applications in diverse industries.

October 2023: Tesa introduced a new production site in Haiphong, Vietnam, enhancing regional production capacity and supply chain efficiency. This strategic move ensures reliable product availability, optimized transport capacities, and streamlined raw material procurement in the region.

Splicing Tapes Market Segmentation

Splicing Tapes Type Outlook

- Single-Sided Splicing Tapes

- Double-Sided Splicing Tapes

Splicing Tapes Material Outlook

- Paper-Based Splicing Tapes

- Plastic-Based Splicing Tapes

- Foam-Based Splicing Tapes

Splicing Tapes Adhesive Type Outlook

Splicing Tapes Application Outlook

Splicing Tapes Regional Outlook

|

Report Attribute/Metric

|

Details

|

|

Market Size 2024

|

USD 601.09 Million

|

|

Market Size 2025

|

USD 611.52 Million

|

|

Market Size 2035

|

USD 796.17 Million

|

|

Compound Annual Growth Rate (CAGR)

|

2.6 % (2025-2035)

|

|

Base Year

|

2024

|

|

Forecast Period

|

2025-2035

|

|

Historical Data

|

2019-2023

|

|

Forecast Units

|

Value (USD Million)

|

|

Report Coverage

|

Revenue Forecast, Competitive Landscape, Growth Factors, And Trends

|

|

Segments Covered

|

type , Material, Adhesive Type, application , And Region

|

|

Geographies Covered

|

North America, Europe, Asia Pacific, Middle East & Africa, And South America

|

|

Countries Covered

|

The U.S, Canada, Mexico, Germany, France, Uk, China, Japan, India, Australia, South Korea, Use, And Brazil

|

|

Key Companies Profiled

|

3M, AVERY DENNISON CORPORATION, Nitto Denko Corporation, Tesa SE, Scapa Group PLC, IPG (Intertape polymer group), Shurtape Technologies, LLC, ORAFOL, Adhesives Research, Inc., ECHO tape.

|

|

Key Market Opportunities

|

· Emergence of Smart Packaging Solutions

· impact Analysis of COVID-19

|

|

Key Market Dynamics

|

· Growing Demand in Electronics Packaging

· Expansion of E-commerce Business

|

Frequently Asked Questions (FAQ):

USD 601.09 Million In 2024

3M, AVERY DENNISON CORPORATION, Nitto Denko Corporation, Tesa SE, Scapa Group PLC, IPG (Intertape polymer group), Shurtape Technologies, LLC, ORAFOL, Adhesives Research, Inc., ECHO tape.

The Double-Sided Splicing Tapes Dominated The Market In 2024.