- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

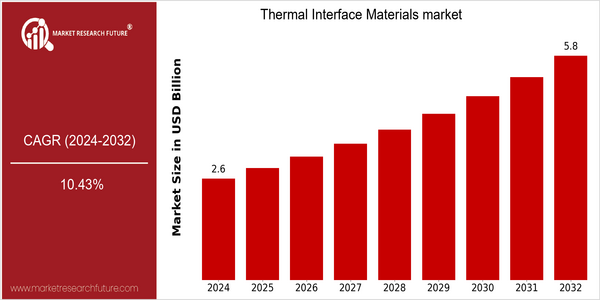

| Year | Value |

|---|---|

| 2024 | USD 2.63 Billion |

| 2032 | USD 5.82 Billion |

| CAGR (2024-2032) | 10.43 % |

Note – Market size depicts the revenue generated over the financial year

The global market for thermally insulating materials is expected to grow, with a current value of $ 2.63 billion in 2024, projected to reach $ 5.82 billion in 2032. This will be a very high CAGR of 10.43% over the forecast period. This growth is mainly due to the increasing demand for efficient thermal management solutions in many industries, especially in the electronics, automotive and renewable energy sectors. Devices are becoming more powerful and smaller, and heat dissipation has never been more important. Also, technological developments such as the development of high-performance materials and new production processes will boost the market. Companies such as Henkel, 3M and Dow are at the forefront of this development, investing in research and development to improve their products and broaden their product portfolios. Strategic alliances and cooperation are also reshaping the competitive landscape. As the importance of thermal management in improving the efficiency and reliability of products continues to grow, the market for thermally insulating materials is expected to grow steadily.

Regional Market Size

Regional Deep Dive

The TIM market is experiencing significant growth in different regions, owing to the increasing demand for efficient thermal management solutions in the electronic, automobile and industrial applications. In North America, the market is characterized by the strong presence of key players and a strong focus on innovation, especially in the semiconductor and consumer electronics industries. Europe is experiencing a significant increase in demand, mainly due to strict regulations on energy efficiency and a growing focus on electric vehicles. The Asia-Pacific region is experiencing rapid growth, driven by a growing demand for electronics and an increase in investments in the field of renewable energy. In the Middle East and Africa, TIM solutions are gradually being adopted, especially in the oil and gas industry, while in Latin America, a steady growth is being experienced as industries modernize and seek improved thermal management.

Europe

- Europe's TIM market is significantly shaped by the automotive industry's shift towards electric vehicles, with companies such as Dow and Laird Technologies developing specialized materials to meet the thermal management needs of EV batteries.

- The European Union's stringent regulations on electronic waste and energy consumption are pushing manufacturers to invest in sustainable TIM solutions, fostering innovation and collaboration among industry players.

Asia Pacific

- The Asia-Pacific region is witnessing rapid growth in the TIM market, primarily due to the expansion of the electronics manufacturing sector, with major players like Shin-Etsu Chemical and Momentive Performance Materials investing heavily in R&D.

- Government initiatives in countries like China and India to promote renewable energy and electric vehicles are driving demand for advanced thermal management solutions, creating new opportunities for TIM manufacturers.

Latin America

- Latin America's TIM market is slowly gaining traction as industries modernize, with local companies beginning to recognize the importance of effective thermal management in improving product performance and reliability.

- The region's growing electronics and automotive sectors are prompting manufacturers to explore advanced TIM solutions, although challenges such as economic instability and regulatory hurdles remain.

North America

- The North American TIM market is heavily influenced by advancements in semiconductor technology, with companies like 3M and Henkel leading the charge in developing innovative materials that enhance thermal conductivity and reliability.

- Recent regulatory changes aimed at improving energy efficiency in electronics have prompted manufacturers to adopt advanced TIM solutions, thereby driving market growth and innovation.

Middle East And Africa

- In the Middle East and Africa, the TIM market is gradually evolving, with a focus on the oil and gas sector, where companies like ThermoTek are developing specialized materials to withstand extreme temperatures and harsh environments.

- The region's economic diversification efforts are leading to increased investments in technology and infrastructure, which are expected to boost the adoption of thermal interface materials in various industries.

Did You Know?

“Did you know that the thermal conductivity of some advanced thermal interface materials can exceed 10 W/mK, making them essential for high-performance applications in electronics and automotive industries?” — Thermal Interface Materials: A Comprehensive Guide, 2023

Segmental Market Size

The thermal management of the products plays a major role in the TIM sector, which plays a key role in improving the heat transfer between the heat source and the heat sink. This market is currently growing, driven by the increasing demand from the electronics, automobile and green energy sectors. The cooling needs of high-performance computers and the increasing number of electric vehicles require better cooling systems. The use of TIMs is now in a mature phase, with Henkel and 3M leading the way in the development and implementation of new products. In the electronics industry, TIMs are used in the CPUs and GPUs of digital products, in electric vehicles, where they are used to cool the batteries. The macro-economic trend of promoting sustainable development and energy-saving technology is driving this industry to grow. Furthermore, the development of materials and the development of graphene-based TIMs will have a major impact on the future development of this industry.

Future Outlook

The market for thermally conductive materials is expected to increase from $2.63 billion in 2024 to $5.82 billion by 2032, at a CAGR of 10.43%. The increase is due to the increasing demand for thermally conductive materials in various industries such as electronics, automotive and wind power. The increase is due to the fact that the size and power of the devices is decreasing, and the heat dissipation technology is improving. As a result, the penetration rate of advanced TIMs in both industrial and consumer applications will be higher.The main technological advancements such as the development of high-performance materials such as graphene and phase change materials are expected to further improve the heat dissipation performance and reliability of TIMs. The adsorption capacity of the TIMs will also be improved. In addition, the stringent regulations on energy conservation and carbon emissions will drive the market for advanced thermal management solutions. , The integration of TIMs into electric vehicles and the trend of miniaturization in the electronics industry will also play an important role in shaping the market landscape. The TIM market will be undergoing a transformation.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2023 | USD 2.35 billion |

| Growth Rate | 10.43% (2024-2032) |

Thermal Interface Materials Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.