Global Twin Screw Extruders Market Overview

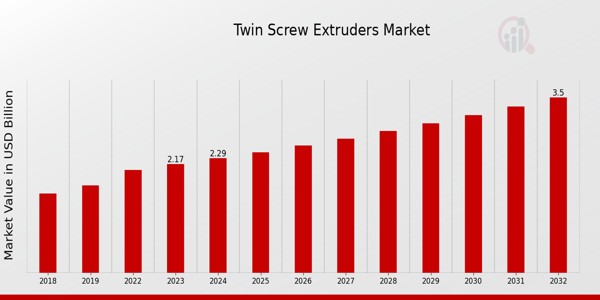

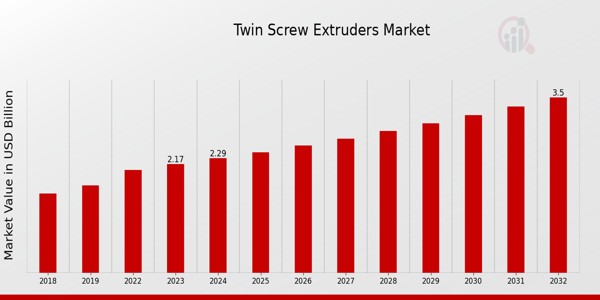

As per MRFR analysis, the Twin Screw Extruders Market Size was estimated at 2.41 (USD Billion) in 2024. The Twin Screw Extruders Market Industry is expected to grow from 2.54 (USD Billion) in 2025 to 4.10 (USD Billion) till 2034, at a CAGR (growth rate) is expected to be around 5.48% during the forecast period (2025 - 2034).

Key Twin Screw Extruders Market Trends Highlighted

The Twin Screw Extruders Market is experiencing notable growth driven by several key market drivers. The rising demand for polymer processing in various industries, including automotive, packaging, and construction, has significantly boosted the adoption of twin screw extruders. Their ability to provide enhanced mixing, flexibility in processing, and higher efficiency in production has made them a preferred choice over single screw extruders. Technological advancements, such as the development of new materials and enhanced extrusion processes, further support market expansion. Stringent regulations regarding the use of sustainable materials also compel manufacturers to seek efficient production technologies, adding to the market's momentum.In this ever-changing scenario, many chances are up for grabs. The growing focus on recycling and the use of environmentally friendly materials provides immense opportunities for twin screw extruder manufacturers. There is a great opportunity for companies in this direction to develop and upgrade their machines to enable better and easier recycling processes. The pharmaceutical and food factories’ constantly growing demand for improved product quality and safety, resulting in increased use of twin screw extrusion, also offers good growth prospects. Developing regions, too, have underdeveloped potential as these regions are also developing their manufacturing industries, which would need advanced extrusion technologies.

Recent trends within the market highlight a shift towards automation and smart manufacturing practices. The integration of Industry 4.0 concepts, such as IoT and AI, into extrusion processes is becoming increasingly common. This shift not only boosts productivity and efficiency but also enhances data collection and analysis capabilities. Environmental sustainability remains a focal point, with an ongoing trend toward developing energy-efficient machinery and processes. Additionally, collaborative partnerships between technology providers and manufacturers are gaining traction, leading to innovative solutions tailored to meet specific industry requirements.Overall, the twin screw extruders market is poised for growth as it adapts to meet the needs of various sectors while leveraging technological advancements and sustainability initiatives.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Twin Screw Extruders Market Drivers

Growing Demand for High-Quality Compounds

The Twin Screw Extruders Market Industry is witnessing a significant increase in the demand for high-quality compounded materials. As industries such as automotive, packaging, and consumer goods push for better performance and customization, manufacturers are looking for efficient solutions to meet these requirements. Twin screw extruders offer the unique advantage of precise control over the mixing and processing of materials, enabling the production of high-quality compounds that cater to specific industry needs.This intrinsic capability supports the adaptation to various materials, including plastics, rubber, and food products, which is essential in today's market where product differentiation is key for competitive advantage. As more businesses seek to innovate and improve their offerings, the reliance on advanced extrusion technology becomes increasingly vital. Furthermore, the rise of biodegradable materials and eco-friendly solutions is shaping the landscape, leading to the integration of twin screw extruders for the effective handling of these materials.This evolution reinforces the significance of high-performance extrusion methods, contributing to the steady growth of the Twin Screw Extruders Market, highlighting the technology's versatility and essential role in meeting modern material demands.

Technological Advancements in Extrusion Processes

Technological advancements are playing a crucial role in driving growth within the Twin Screw Extruders Market Industry. The continuous development of extrusion technology leads to improved processing capabilities, efficiency, and product quality. Innovations such as the introduction of advanced screw designs, better control systems, and highly efficient cooling mechanisms enable manufacturers to optimize production processes. These technologies not only reduce operational costs but also enhance the overall quality and performance of extruded products.As companies strive to implement smarter manufacturing practices, the integration of automation and monitoring systems in twin screw extruders becomes imperative. This results in a higher degree of operational precision and reliability, further supporting the expansion of the market.

Increasing Applications in Various Industries

The expanding range of applications for twin screw extruders across various industries acts as a significant driver for the Twin Screw Extruders Market Industry. These extruders are extensively utilized in sectors such as pharmaceuticals, food processing, plastics, and more. Their ability to efficiently blend, melt, and shape diverse materials makes them indispensable in developing specialized products. Industries are increasingly recognizing the benefits of twin screw extruders for achieving better consistency, product quality, and faster production cycles.As more sectors adopt these machines for their processing needs, the market continues to experience significant growth, driven by the versatility and adaptability of twin screw extruders.

Twin Screw Extruders Market Segment Insights

Twin Screw Extruders Market Application Insights

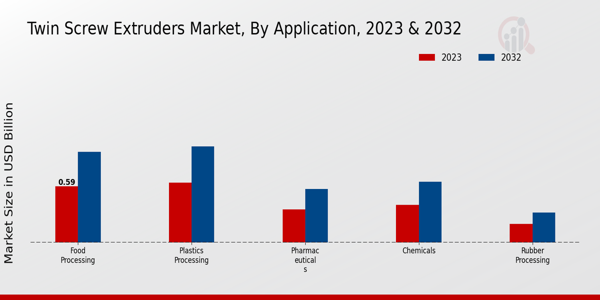

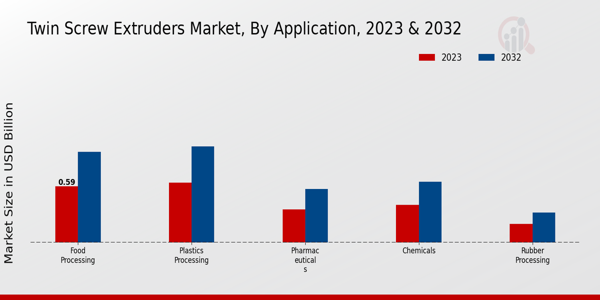

The Twin Screw Extruders Market has shown significant expansion within its application segment, highlighting the diverse functionalities of twin screw extruders across various industries. In 2023, the overall market was valued at 2.17 billion USD, reflecting the growth trajectory of this segment. The food processing application, with a valuation of 0.593 billion USD in 2023, indicates a rising demand for twin screw extruders in the food industry, driven by the need for innovative processing techniques and the enhancement of product quality. This segment is expected to reach 0.958 billion USD by 2032, showcasing its growing importance in meeting consumer preferences for processed food products. Plastics processing is another major player in the Twin Screw Extruders Market, valued at 0.634 billion USD in 2023, making it a significant domain due to the increasing use of plastics in various applications. By 2032, its estimation will rise to 1.017 billion USD, demonstrating the sustained demand for efficient and advanced manufacturing processes in the plastics sector. The pharmaceuticals sector, while comparatively smaller, reflects critical growth with valuations of 0.349 billion USD in 2023, forecasted to increase to 0.567 billion USD in the coming years. This underscores the necessity for precise and consistent processing methods in pharmaceutical applications, emphasizing the essential role of twin screw extruders in producing complex formulations.In the chemicals sector, the market valuation of 0.398 billion USD in 2023 is anticipated to grow to 0.642 billion USD by 2032. The significant rise indicates increasing reliance on twin screw technology for efficient chemical blending and processing. Regarding the rubber processing application, which is the least dominant within the segment, with a value of 0.195 billion USD in 2023, the growth to 0.317 billion USD by 2032 reflects a gradual increase in demand for better processing techniques in rubber manufacturing. Overall, the Twin Screw Extruders Market segmentation highlights significant opportunities for growth driven by technological advancements, the need for innovative processing solutions, and increasing consumer demands across these applications, thus positioning the sector for a robust expansion in the forthcoming years.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Twin Screw Extruders Market Product Type Insights

The Twin Screw Extruders Market is projected to reach 2.17 USD Billion in 2023, showcasing steady growth in the field of polymers, food, and pharmaceuticals. Within the market, the Product Type segmentation plays a crucial role, encompassing significant types like Co-rotating and Counter-rotating Twin Screw Extruders. Co-rotating twin screw extruders are recognized for their efficient mixing and conveying capabilities, making them preferable in applications requiring uniformity and complex processing. In contrast, Counter-rotating twin screw extruders excel in applications where material shear rates need to be controlled, therefore ensuring the quality of thermally sensitive materials.As industries seek enhanced processing capabilities and flexibility, these types are expected to see a notable share in market growth. The Twin Screw Extruders Market data indicates that the increase in demand for innovative polymer processing techniques drives these segments, highlighting their importance in enhancing production efficiency and reducing operational costs. The overall market is likely to benefit from technological advancements and the expansion of the manufacturing sector, thus fostering a robust landscape for future development.

Twin Screw Extruders Market Material Type Insights

In 2023, the Twin Screw Extruders Market was valued at approximately 2.17 billion USD, reflecting a robust growth trajectory driven by diverse applications across multiple industries. Within the Material Type segment, key categories include Thermoplastics, Thermosetting Plastics, Elastomers, and Composites, each playing a pivotal role in the market landscape. Thermoplastics, known for their recyclability and versatility, continue to dominate due to their widespread use in packaging, automotive, and consumer goods. Thermosetting Plastics, appreciated for their exceptional durability and heat resistance, are gaining traction in electrical applications.Elastomers provide excellent elasticity and resilience, making them integral in manufacturing seals and gaskets, while Composites are increasingly favored for their lightweight and strength properties, crucial for sectors such as aerospace and construction. The overall market growth is supported by rising demand for sustainable materials and advanced manufacturing technologies, positioning the Twin Screw Extruders Market data as a crucial aspect for industries aiming to enhance product performance and reduce environmental impact. These trends and the segmentation illuminate the broader Twin Screw Extruders Market statistics, showcasing opportunities and challenges for industry players.

Twin Screw Extruders Market End Use Industry Insights

The Twin Screw Extruders Market found a substantial valuation of 2.17 USD Billion in 2023, reflecting its robust presence across various end-use industries. This market is experiencing significant growth, driven by the rising demand for high-efficiency extrusion techniques that improve product quality and processing speed. Industries such as Aerospace and Automotive are particularly crucial to the Twin Screw Extruders Market due to their requirement for advanced materials and high-performance components. The Construction sector also plays a vital role, with an increasing demand for durable building materials, while the Electronics segment benefits from the need for innovative plastic products.Consumer Goods is another important domain, where efficient material processing is essential for meeting evolving customer preferences. Such dynamics illustrate the market's adaptability and its ability to cater to different industrial needs effectively. Overall, the Twin Screw Extruders Market statistics emphasize the interconnectedness of these industries and the value of extruder technology within them.

Twin Screw Extruders Market Regional Insights

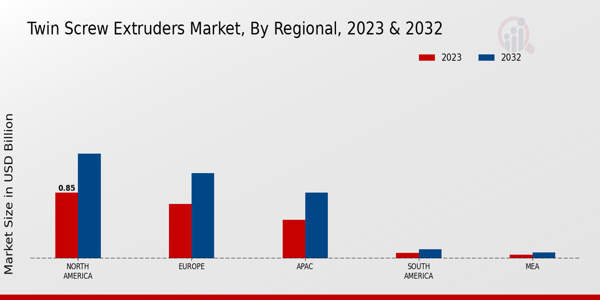

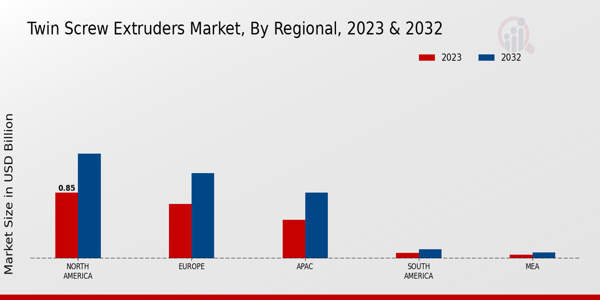

The Twin Screw Extruders Market is witnessing notable growth across various regions. In 2023, North America holds a significant market value of 0.85 USD Billion, expected to grow to 1.35 USD Billion by 2032, making it a major player with a robust industrial base and rising demand in the processing of plastics and food sectors. Europe follows closely, having a market value of 0.7 USD Billion in 2023 and projected to reach 1.1 USD Billion in 2032, driven by technological advancements and a strong automotive industry. The APAC region currently has a market value of 0.5 USD Billion in 2023, with expectations of growing to 0.85 USD Billion by 2032, highlighting its emerging market potential due to rapid industrialization and increased manufacturing activities.In contrast, South America and MEA exhibit smaller market valuations, at 0.07 USD Billion and 0.05 USD Billion in 2023, respectively, but are anticipated to expand as local industries develop and foreign investments increase. Overall, the Twin Screw Extruders Market segmentation illustrates a diverse landscape, where North America and Europe dominate due to established industries, while APAC presents significant opportunities for future growth, reflecting the dynamics of the Twin Screw Extruders Market revenue trends.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Twin Screw Extruders Market Key Players and Competitive Insights

The Twin Screw Extruders Market has become increasingly competitive, driven by advancements in technology and a growing demand for high-performance extrusion solutions across various industries, including packaging, automotive, and pharmaceuticals. Manufacturers are consistently enhancing their product offerings to improve efficiency, productivity, and flexibility, leading to a dynamic landscape where companies compete on multiple fronts, such as innovation, customer service, and market reach. The infusion of new technological developments, particularly in control systems and material processing capabilities, has enabled businesses to optimize the performance of twin screw extruders, catering specifically to the unique needs of their clientele and establishing a competitive edge.KraussMaffei stands out in the Twin Screw Extruders Market due to its strong commitment to innovation and research and development. The company has garnered a reputation for producing high-quality extruders that are engineered for versatility and efficiency, effectively addressing the varying needs of customer applications. Its robust manufacturing capabilities encompass both standard and customized extruder designs, which appeal to a diverse range of industries. KraussMaffei's flexible production processes and advanced technology integration enable rapid response to customer demands, solidifying its position as a leader in the market. Additionally, its global presence and established customer relationships provide a competitive advantage that facilitates penetration into emerging markets, further enhancing its strength in the twin screw extruder sector.Zhejiang Fongming is also a prominent player in the Twin Screw Extruders Market, recognized for its comprehensive range of extruder products tailored for diverse applications. The company emphasizes the importance of technology by continuously refining its manufacturing processes and investing in significant research and development initiatives. This focus on innovation is reflected in its ability to produce highly efficient twin screw extruders that meet the stringent requirements of various industries. Moreover, Zhejiang Fongming benefits from a strong market presence, particularly in Asia, where it has built a solid reputation among manufacturers looking for reliable and cost-effective solutions. The company’s commitment to quality, coupled with its customer-centric approach and competitive pricing strategies, further strengthens its standing in the highly dynamic twin screw extruder market.

Key Companies in the Twin Screw Extruders Market Include

- KraussMaffei

- Zhejiang Fongming

- Reifenhäuser

- Xtrutech

- Leistritz

- DavisStandard

- Milacron

- Everplast

- Nanjing Haisi

- Mitsubishi

- JSW

- Berstorff

- Coperion

- BattenfeldCincinnati

Twin Screw Extruders Market Industry Developments

Recent developments in the Twin Screw Extruders Market highlight significant movements among key players. Milwaukee-based Davis-Standard has introduced innovative solutions, enhancing the operational efficiency of their extruders. KraussMaffei is focusing on sustainable applications, targeting the growing demand for eco-friendly materials, while Leistritz has reported a boost in orders for their advanced twin screw extruder models, reflecting a rising interest in polymer processing. On the acquisition front, Coperion announced a strategic partnership aimed at advancing technology sharing, a move that is expected to strengthen its market position against competitors like Reifenhäuser and JSW. Additionally, Everplast's recent expansion in its manufacturing capabilities indicates a broader trend of increasing production capacity across the sector. Companies like Milacron and Nanjing Haisi are also enhancing their focus on automation and smart technology integration, suggesting a shift toward Industry 4.0 trends. As the demand for customized extrusion solutions continues to grow, these developments collectively signal a vibrant and evolving landscape in the Twin Screw Extruders Market, with companies adapting to emerging trends in sustainability and technology.

- Twin Screw Extruders Market Segmentation Insights

- Twin Screw Extruders Market Application Outlook

- Food Processing

- Plastics Processing

- Pharmaceuticals

- Chemicals

- Rubber Processing

- Twin Screw Extruders Market Product Type Outlook

- Co-rotating Twin Screw Extruders

- Counter-rotating Twin Screw Extruders

- Twin Screw Extruders Market Material Type Outlook

- Thermoplastics

- Thermosetting Plastics

- Elastomers

- Composites

- Twin Screw Extruders Market End Use Industry Outlook

- Aerospace

- Automotive

- Construction

- Electronics

- Consumer Goods

| Report Attribute/Metric |

Details |

|

Market Size 2024

|

2.41 (USD Billion)

|

|

Market Size 2025

|

2.54 (USD Billion)

|

|

Market Size 2034

|

4.10 (USD Billion)

|

|

Compound Annual Growth Rate (CAGR)

|

5.48% (2025 - 2034)

|

|

Report Coverage

|

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends

|

|

Base Year

|

2024

|

|

Market Forecast Period

|

2025 - 2034

|

|

Historical Data

|

2019 - 2023

|

| Market Forecast Units |

USD Billion |

| Key Companies Profiled |

KraussMaffei, Zhejiang Fongming, Reifenhäuser, Xtrutech, Leistritz, DavisStandard, Milacron, Everplast, Nanjing Haisi, Mitsubishi, JSW, Berstorff, Coperion, BattenfeldCincinnati |

| Segments Covered |

Application, Product Type, Material Type, End Use Industry, Regional |

| Key Market Opportunities |

Rising demand in food processing, Growth in renewable energy applications, Advancements in polymer processing technology, Increasing adoption in pharmaceuticals, Expanding manufacturing capabilities in emerging markets |

| Key Market Dynamics |

Rising demand for customized products, Increasing adoption in food processing, Growth of polymer processing industries, Technological advancements in extrusion, Expanding applications in pharmaceuticals |

| Countries Covered |

North America, Europe, APAC, South America, MEA |

Frequently Asked Questions (FAQ) :

The Twin Screw Extruders Market is expected to be valued at 4.10 USD Billion by 2034.

The expected CAGR for the Twin Screw Extruders Market during this period is 5.48%.

North America is projected to have the largest market share, valued at 1.35 USD Billion by 2032.

Key applications include Food Processing, Plastics Processing, Pharmaceuticals, Chemicals, and Rubber Processing.

The Food Processing application is expected to reach a market value of 0.958 USD Billion by 2032.

Major players include KraussMaffei, Reifenhäuser, DavisStandard, and Coperion among others.

The Plastics Processing application is estimated to reach a market size of 1.017 USD Billion by 2032.

The European market is expected to grow to a value of 1.1 USD Billion by 2032.

The Chemicals application is expected to have a market value of 0.642 USD Billion by 2032.

The Rubber Processing segment is projected to grow to a market size of 0.317 USD Billion by 2032.