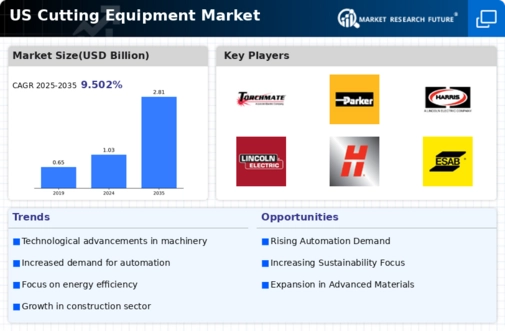

The competitive insights of the US Cutting Equipment Market reveal a dynamic landscape characterized by innovation, technological advancements, and a diverse range of players vying for market share. With the increasing demand for precision and efficiency in various industries such as manufacturing, construction, and metalworking, companies in this sector are continuously adapting their strategies to meet the evolving needs of customers. Market participants are focusing on enhancing product offerings through research and development, collaborations, and strategic partnerships.

The competitive environment is intensified by factors such as pricing strategies, distribution channels, and the integration of automation and software solutions, which have become crucial for maintaining a competitive edge.

As the industry matures, understanding the competitive forces at play will be paramount for stakeholders aiming to capitalize on market opportunities.Torchmate stands out in the US Cutting Equipment Market by leveraging its extensive experience and domain expertise. The company is particularly known for its reliable and user-friendly plasma cutting systems designed to meet the diverse needs of customers ranging from small fabrication shops to larger manufacturing enterprises. Torchmate has built a strong reputation for quality and performance, leading to a loyal customer base.

Its commitment to producing rugged, high-quality machines, coupled with a focus on customer support and aftersales services, has significantly bolstered its market presence.

Furthermore, Torchmate's adaptability in integrating advanced technologies and customization options allows it to cater to a wide range of applications, reinforcing its competitive position in an ever-evolving market landscape.Parker Hannifin also plays a significant role within the US Cutting Equipment Market, known for its robust portfolio of advanced technology solutions that include motion and control systems.

The company provides a variety of cutting technologies optimized for efficiency and precision, thus addressing the diverse needs of industries such as aerospace, automotive, and metal fabrication. Parker Hannifin emphasizes innovation and supports market growth through consistent investment in research and development. Its market presence has been further strengthened by strategic mergers and acquisitions, allowing the company to expand its range of cutting equipment and enhance its service capabilities. The company's strengths lie in its ability to provide integrated solutions that combine cutting equipment with related automation and control features, ensuring customers receive comprehensive support.

Overall, Parker Hannifin is well-positioned to continue its growth in the US Cutting Equipment Market by maintaining its focus on quality, efficiency, and delivering value through comprehensive solutions.