Focus on Precision Engineering

Precision engineering is becoming a cornerstone of the metal sawing-machine market, as industries demand higher accuracy in metal cutting processes. The need for intricate designs and tight tolerances in products is pushing manufacturers to seek advanced sawing solutions that can deliver exceptional precision. In 2025, it is estimated that the market for precision-engineered components will grow by 20%, further emphasizing the importance of high-quality sawing machines. This focus on precision not only enhances product quality but also reduces material waste, aligning with broader industry goals of efficiency and sustainability. As a result, the metal sawing-machine market is likely to see increased investment in technologies that support precision engineering, driving innovation and competitiveness.

Emergence of Advanced Materials

The introduction of advanced materials in various industries is significantly influencing the metal sawing-machine market. As sectors such as aerospace and automotive increasingly adopt lightweight and high-strength materials, the demand for specialized sawing machines capable of cutting these materials is on the rise. In 2025, it is anticipated that the market for advanced materials will grow by approximately 15%, necessitating the development of sawing technologies that can accommodate these innovations. This trend compels manufacturers to invest in machines that offer enhanced cutting capabilities and precision, thereby driving advancements within the metal sawing-machine market. The ability to effectively process advanced materials will likely become a key differentiator for companies in this competitive landscape.

Rising Demand in Manufacturing Sector

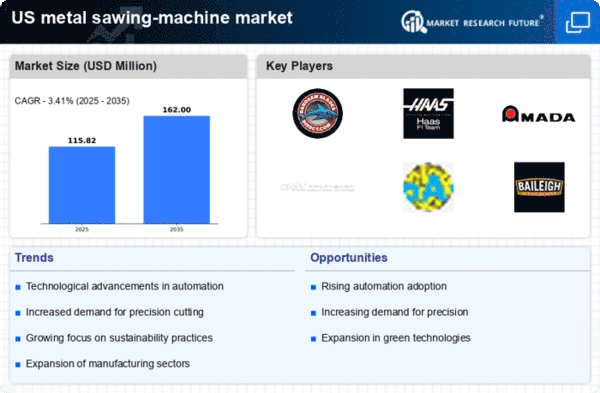

The metal sawing-machine market is experiencing a notable surge in demand, primarily driven by the expansion of the manufacturing sector in the US. As industries such as automotive, aerospace, and construction continue to grow, the need for precise and efficient metal cutting solutions becomes increasingly critical. In 2025, the manufacturing sector is projected to contribute approximately $2 trillion to the US economy, indicating a robust environment for metalworking equipment. This growth is likely to propel investments in advanced sawing technologies, enhancing productivity and reducing operational costs. Consequently, manufacturers are seeking high-performance sawing machines that can meet stringent quality standards, thereby fostering innovation within the metal sawing-machine market.

Increased Automation in Production Processes

Automation is transforming the landscape of the metal sawing-machine market, as manufacturers strive to enhance efficiency and reduce labor costs. The integration of automated systems in production lines allows for higher precision and consistency in metal cutting operations. In 2025, it is estimated that around 30% of manufacturing processes in the US will be automated, leading to a significant uptick in demand for advanced sawing machines equipped with automation features. This trend not only streamlines operations but also minimizes waste, aligning with the industry's push for sustainability. As a result, the metal sawing-machine market is likely to witness a shift towards machines that incorporate smart technologies, further driving market growth.

Growing Investment in Infrastructure Development

The metal sawing-machine market is poised to benefit from the increasing investment in infrastructure development across the US. With government initiatives aimed at revitalizing transportation networks, energy projects, and public facilities, the demand for metalworking equipment is expected to rise. In 2025, infrastructure spending is projected to reach approximately $1 trillion, creating a favorable environment for the metal sawing-machine market. This influx of capital is likely to stimulate demand for high-quality sawing machines capable of handling diverse materials and complex cutting tasks. As infrastructure projects ramp up, manufacturers will seek reliable and efficient sawing solutions to meet the growing needs of the construction and engineering sectors.