US Tension Control Market Overview:

As per MRFR analysis, the US Tension Control Market Size was estimated at 325.5 (USD Million) in 2023. The US Tension Control Market Industry is expected to grow from 343(USD Million) in 2024 to 616.13 (USD Million) by 2035. The US Tension Control Market CAGR (growth rate) is expected to be around 5.469% during the forecast period (2025 - 2035).

Key US Tension Control Market Trends Highlighted

The US Tension Control Market is seeing notable trends driven by advancements in technology and an increasing focus on precision in manufacturing processes. Key market drivers include the rising demand for high-quality products across various industries, particularly in automotive and aerospace sectors. These industries are adopting tension control systems to improve product longevity and reduce operational costs. Furthermore, the push for automation in manufacturing is propelling the adoption of advanced tension control solutions that enhance process efficiency and accuracy.

Opportunities in the US market are abundant, especially with the expanding adoption of smart manufacturing techniques.Industries are looking for solutions that integrate seamlessly with existing systems while offering real-time data monitoring and analysis. This trend opens avenues for companies that can provide innovative tension control systems with IoT capabilities, enabling manufacturers to achieve better performance and adapt to changing production needs. In recent times, the market is experiencing a shift towards sustainability, with manufacturers prioritizing eco-friendly materials and energy-efficient technologies. This is driven in part by regulations set forth by government agencies that emphasize sustainable manufacturing practices.

The trend towards digitization and the use of big data analytics in tension control systems is also gaining traction, allowing companies to make more informed decisions and optimize their production processes.Overall, the US Tension Control Market is evolving, focusing on efficiency, sustainability, and technological integration, which will continue to shape its future trajectory.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

US Tension Control Market Drivers

Increasing Demand for Automation in Manufacturing Processes

The push towards automation and Industry 4.0 is significantly affecting the US Tension Control Market Industry. The integration of automated solutions in production lines has led to a critical need for precision tension control systems to ensure consistent product quality and efficiency. According to the National Association of Manufacturers, approximately 80% of manufacturers in the US have adopted automation technologies in some capacity, driving the demand for advanced tension control systems.

This growing trend not only enhances productivity but also reduces operational costs, positioning automated tension control solutions as a key component of modern manufacturing. Companies such as Rockwell Automation and Siemens are at the forefront of providing integrated solutions that contribute to this market growth. Their expanded product offerings focused on optimizing tension control within automated systems are indicative of an overall industry shift towards enhanced manufacturing efficiency.

Technological Advancements and Innovations in Tension Control Systems

The continuous advancements in technology are influencing the US Tension Control Market Industry significantly. Innovations such as smart tension control systems equipped with advanced sensors and real-time monitoring capabilities are increasingly being embraced.

A report by the U.S. Patent and Trademark Office noted a 25% year-over-year increase in patents related to tension control technologies, highlighting the focus on developing more efficient and effective solutions.Major players like ABB and Omron are investing heavily in Research and Development (R&D) to enhance these technologies, which allow for precise control in dynamic environments, thus fostering the market's growth potential. These advancements not only improve operational efficiencies but also support compliance with stringent manufacturing standards, further bolstering market prospects.

Rising Focus on Quality Control in Production

With increasing competition among manufacturers, there is a heightened focus on quality control measures, which directly impacts the US Tension Control Market Industry. High-quality products correlate with effective tension control systems that minimize defects and improve production consistency. According to the American Society for Quality, businesses that invest in quality control see a return on investment of approximately $3 to $5 for every dollar spent.

As more entities in the US emphasize quality assurance to meet customer expectations and regulatory compliance, the demand for reliable tension control solutions rises. Organizations like ASQ advocate for robust quality management practices, urging manufacturers to integrate sophisticated tension control systems into their processes as a means of ensuring exceptional product standards.

US Tension Control Market Segment Insights:

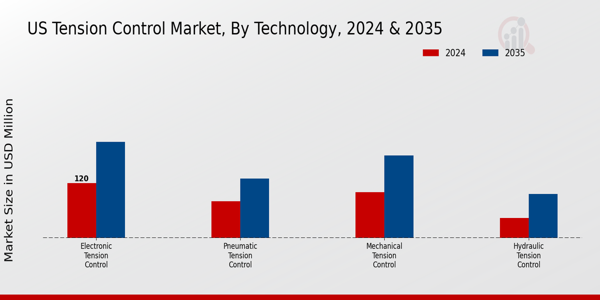

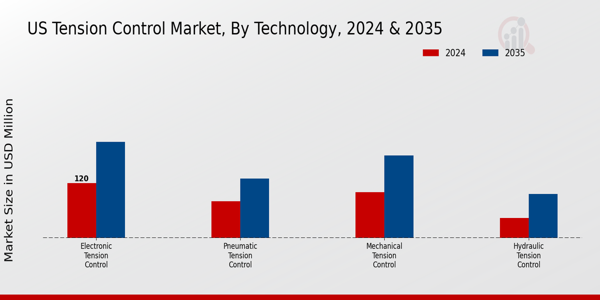

Tension Control Market Technology Insights

The US Tension Control Market within the Technology segment is witnessing a robust evolution, characterized by advances and innovations aimed at optimizing production processes across various industries. This market is molded by an increasing demand for precision in tension control systems, which are critical in applications ranging from textile manufacturing to industrial automation.

The Mechanical Tension Control methodologies, which employ physical mechanisms to regulate tension, continue to serve as the backbone for many traditional manufacturing setups; they are valued for their reliability and low maintenance costs.In contrast, Electronic Tension Control technologies are gaining traction due to their ability to provide real-time tension adjustments and data analytics, enabling operators to achieve higher efficiency and reduce waste.

Pneumatic Tension Control systems leverage compressed air to maintain tension, offering advantages in systems where high-speed production is a necessity, making them relevant for various sectors, including printing and packaging. Meanwhile, Hydraulic Tension Control units are preferred in settings that demand high force and precision, facilitating smoother operations in heavier machinery applications.The diversity of these technologies contributes to the comprehensive nature of the US Tension Control Market segmentation, wherein each method addresses specific operational challenges and meets the expanding needs of manufacturers striving for excellence in product quality and production speed.

Additionally, the acceleration of Industry 4.0 and increased automation are major growth drivers for these technologies, as businesses look to integrate smarter, more efficient tension control solutions into their operational frameworks, thereby embracing enhanced flexibility and responsiveness to market demands.Challenges, such as the substantial initial investment and a necessity for skilled personnel to operate these advanced systems, do persist; however, the opportunities for innovation and market expansion remain vast, particularly as industries pursue high standards of precision and integration. Thus, the Technology segment of the US Tension Control Market presents a dynamic landscape that is poised for significant growth while adapting to evolving industrial requirements.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Tension Control Market Application Insights

The US Tension Control Market, segmented by Application, comprises critical industries such as Textiles, Printing, Packaging, Automotive, and Aerospace. Each application plays a significant role in driving market dynamics and reflects the growing need for precision and control in production processes. The Textiles sector highlights the demand for quality and uniformity, using tension control to ensure optimal results in fabric production. Similarly, the Printing industry benefits from tension management for consistent print quality and efficiency.

In Packaging, tension control technology is vital in handling materials securely, contributing to reduced waste and improved safety in operations. The Automotive sector relies on tension control for enhanced production efficiencies, ensuring that components are assembled with precision to meet stringent safety standards. Meanwhile, Aerospace demands heightened reliability and safety, making tension control technology essential for maintaining high-quality production in this highly regulated field.

Overall, these applications not only showcase the versatility of tension control technologies but also underscore their importance in fostering innovation and efficiency across these key industries in the US economy.As they continue to advance, these applications are expected to fuel market growth and shape the landscape of the US Tension Control Market.

Tension Control Market End Use Insights

The US Tension Control Market, categorized by End Use, demonstrates significant diversity and growth potential across various sectors. The manufacturing segment plays a pivotal role as it encapsulates a wide array of applications, highlighting the importance of precise tension management in production processes and overall efficiency. Industrial applications follow closely, benefiting from advancements in technology that improve operational standards and reduce costs. The commercial segment also claims a noteworthy share, driven by developments in infrastructure and the high demand for reliable tension control in various projects.

Residential use, while smaller in proportion, represents an emerging market segment as more homeowners seek innovative solutions for home improvement and safety. The integration of smart technology and automation into these segments is a notable trend, enhancing user experience and operational efficiency.

Government investment in infrastructure and manufacturing sectors in the US significantly supports growth in these areas, contributing to a robust US Tension Control Market. Moreover, the increasing emphasis on sustainability and energy efficiency across all end uses is shaping the development of new products tailored to meet evolving consumer demands.

Tension Control Market Type Insights

The US Tension Control Market reflects significant growth and diversification across its Type segmentation, which includes Closed-loop Control, Open-loop Control, and Static Tension Control. Closed-loop Control is vital in ensuring precise tension maintenance, making it critical for industries like printing and packaging, where consistent output quality is paramount. Open-loop Control systems offer a simpler alternative, ideal for less demanding applications where cost-effectiveness is prioritized, making it relevant for a range of manufacturing processes.On the other hand, Static Tension Control plays a significant role in applications requiring a stable tension level, such as textile and film industries, ensuring that materials do not stretch or deform during processing.

The continuous demand for enhanced efficiency and product quality is driving investments in advanced tension control technologies, thereby enabling better operational performance and reduced wastage. As industries in the US increasingly prioritize automation and efficiency, the segmentation within the US Tension Control Market is expected to evolve, addressing specific needs and preferences across different sectors effectively.

US Tension Control Market Key Players and Competitive Insights:

The US Tension Control Market is characterized by its dynamic landscape, catering to various industrial applications where precise tension management is crucial for operational efficiency. This market is driven by the growing demand for automation and enhanced control mechanisms across manufacturing sectors, particularly in textiles, packaging, and construction industries.

The competition within this market is influenced by technological advancements, stringent regulatory standards, and the increasing need for innovative solutions that can ensure product quality and performance consistency. Companies are increasingly investing in research and development to enhance their product portfolio, which leads to innovative tension control systems that offer superior performance and reliability. The competitive environment is further shaped by collaborations, partnerships, and strategic alliances, providing a platform for companies to broaden their reach and improve service offerings.Emerson Electric stands out in the US Tension Control Market with its robust product line and technological expertise. Renowned for its advanced automation technologies, Emerson Electric leverages its strong engineering capabilities to deliver high-performance tension control solutions.

The company’s commitment to innovation is reflected in its continual investment in cutting-edge technologies that meet the evolving needs of industries. This positions Emerson as a trusted partner for manufacturers seeking reliable tension control systems that enhance productivity while minimizing operational risks. Additionally, Emerson Electric has established a solid market presence through its extensive distribution networks and strong customer relationships, which serve to reinforce its credibility and reliability within the market.

The company's focus on sustainable practices further solidifies its reputation as a responsible leader in the industry.Parker Hannifin is another key player in the US Tension Control Market, known for its comprehensive range of products and services tailored to meet the diverse needs of various industries. Parker Hannifin offers an impressive portfolio, including tension control systems, pneumatic fixtures, and hydraulic components, which are essential for ensuring optimal performance in manufacturing applications. The company’s strength lies in its engineering excellence and the ability to provide integrated solutions that enhance system efficiency. Parker Hannifin continues to expand its market presence through strategic mergers and acquisitions, increasing its capabilities and ensuring a wider reach within the US.

This agility not only enhances its product offering but also strengthens its competitive position in terms of innovation and customer service. The company’s commitment to sustainability and energy efficiency in its products further adds to its appeal in a market that increasingly values eco-friendly solutions.

Key Companies in the US Tension Control Market Include:

- Emerson Electric

- Parker Hannifin

- Baker Hughes

- Yokogawa Electric

- ABB

- National Instruments

- Rockwell Automation

- Omron

- SICK AG

- Cognex

- Schneider Electric

- General Electric

- Honeywell

- Siemens

- Applied Materials

US Tension Control Market Industry Developments

In recent months, the US Tension Control Market has witnessed significant developments, particularly with companies such as Emerson Electric, Parker Hannifin, Baker Hughes, and Yokogawa Electric making strides in innovation and technology. The market is characterized by the increasing demand for automation and precision in industrial applications, with companies focusing on enhancing their product offerings to maintain competitiveness. Notably, in August 2023, Rockwell Automation announced a strategic acquisition aimed at bolstering its capabilities in smart manufacturing solutions, which is expected to enhance operational efficiencies across various industries.

Additionally, Schneider Electric has launched new products focusing on energy efficiency, aligning with the growing emphasis on sustainable practices within the market. Major players, including General Electric and Honeywell, have reported substantial growth in market valuation, contributing to an overall surge in the sector. Over the last couple of years, advancements in Research and Development activities have accelerated, and market valuation has expanded, driven by innovation and evolving customer needs. As the market landscape continues to transform, these developments underscore a dynamic environment for the US Tension Control Market.

US Tension Control Market Segmentation Insights

Tension Control Market Technology Outlook

- Mechanical Tension Control

- Electronic Tension Control

- Pneumatic Tension Control

- Hydraulic Tension Control

Tension Control Market Application Outlook

- Textiles

- Printing

- Packaging

- Automotive

- Aerospace

Tension Control Market End Use Outlook

- Manufacturing

- Industrial

- Commercial

- Residential

Tension Control Market Type Outlook

- Closed-loop Control

- Open-loop Control

- Static Tension Control

| Report Attribute/Metric Source: |

Details |

| MARKET SIZE 2018 |

325.5(USD Million) |

| MARKET SIZE 2024 |

343.0(USD Million) |

| MARKET SIZE 2035 |

616.13(USD Million) |

| COMPOUND ANNUAL GROWTH RATE (CAGR) |

5.469% (2025 - 2035) |

| REPORT COVERAGE |

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| BASE YEAR |

2024 |

| MARKET FORECAST PERIOD |

2025 - 2035 |

| HISTORICAL DATA |

2019 - 2024 |

| MARKET FORECAST UNITS |

USD Million |

| KEY COMPANIES PROFILED |

Emerson Electric, Parker Hannifin, Baker Hughes, Yokogawa Electric, ABB, National Instruments, Rockwell Automation, Omron, SICK AG, Cognex, Schneider Electric, General Electric, Honeywell, Siemens, Applied Materials |

| SEGMENTS COVERED |

Technology, Application, End Use, Type |

| KEY MARKET OPPORTUNITIES |

Increasing automation in manufacturing, Demand for advanced precision control, Growth in renewable energy sector, Rising need for quality assurance, Expansion of automotive industry |

| KEY MARKET DYNAMICS |

growing demand for automation, increasing manufacturing efficiency, stringent safety regulations, rising need for precision control, technological advancements in equipment |

| COUNTRIES COVERED |

US |

Frequently Asked Questions (FAQ) :

The US Tension Control Market is expected to be valued at approximately 343.0 million USD in 2024.

By 2035, the market is expected to grow to around 616.13 million USD.

The expected CAGR for the market during the forecast period is approximately 5.469%.

The Electronic Tension Control segment is projected to dominate with an expected value of 210.0 million USD by 2035.

Major players include Emerson Electric, Parker Hannifin, Baker Hughes, Yokogawa Electric, and ABB among others.

The Mechanical Tension Control segment is expected to reach a value of 180.0 million USD by 2035.

The Pneumatic Tension Control segment is projected to grow to about 130.0 million USD by 2035.

Key growth drivers include advancements in technology and increasing automation in various industries.

Emerging trends such as the shift towards digitalization and automated systems are expected to positively impact the market.

The current global scenario is fostering innovation and increasing demand for advanced tension control solutions in the market.