Global Weft Sensor Market Overview:

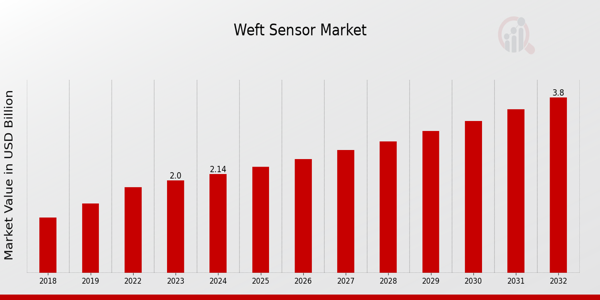

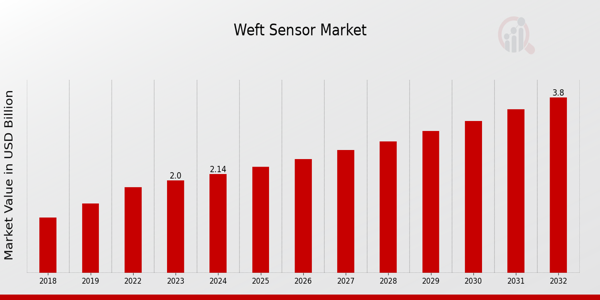

Weft Sensor Market Size was estimated at 1.86 (USD Billion) in 2022. The Weft Sensor Market Industry is expected to grow from 2.0(USD Billion) in 2023 to 3.8 (USD Billion) by 2032. The Weft Sensor Market CAGR (growth rate) is expected to be around 7.41% during the forecast period (2024 - 2032).

Key Weft Sensor Market Trends Highlighted

The Weft Sensor Market is experiencing significant growth driven by the increasing demand for automation across various industries. The adoption of smart textiles and advancements in sensor technology are enhancing the capability of weft sensors, making them more efficient and versatile. Industries such as automotive, healthcare, and manufacturing are particularly keen on implementing these sensors to improve monitoring systems and enhance productivity. Moreover, the push towards sustainable practices is prompting companies to seek ways to optimize production processes, with weft sensors playing a crucial role in this transition. Opportunities within the market are abundant, particularly for innovative solutions that integrate weft sensors with IoT and artificial intelligence.Companies can explore the potential of developing customized sensor solutions tailored to specific industry needs, which could lead to higher customer satisfaction and loyalty.

The growing trend of wearable technology also presents a significant avenue for growth as consumers seek garments that track health metrics and provide real-time feedback. Expanding into emerging markets where industrial automation is taking off can provide additional avenues for revenue and market reach. In recent times, there has been a noticeable shift towards incorporating advanced analytics and data processing capabilities into weft sensors. This trend enables better decision-making and predictive maintenance, ensuring that businesses can drastically reduce downtime.

Furthermore, collaboration between tech companies and apparel manufacturers is becoming more common, fostering innovation and expanding the capabilities of weft sensors. As industries continue to evolve, the demand for sophisticated weft sensors is expected to rise, reflecting the broader trend towards smarter, more connected production environments. This synergy between technology and textile manufacturing will likely redefine how we perceive and utilize everyday fabrics in the near future.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Weft Sensor Market Drivers

Increasing Demand for Automation in Manufacturing Processes

Increased uptake for Weft Sensors across various enterprises worldwide due to rising automation trends and the emerging industrial revolution 4.0. More and more companies are pursuing automation of their operational processes to boost efficiency and cut down workforce costs. Weft sensors play a crucial role in this automation trend by ensuring accurate monitoring and control of textile processes. As the world moves towards Industry 4.0, with a focus on smart factories and interconnected devices, the need for reliable weft sensors becomes even more essential.Automation not only improves productivity but also ensures better quality control, minimizing material wastage and enhancing the overall supply chain.

This shift towards automation is a key driver for the Weft Sensor Market Industry, leading to the adoption of advanced technologies that include smart weft sensors capable of real-time data processing and decision-making. Manufacturers are now looking for innovative solutions to integrate these sensors into their production lines, making them an integral part of modern textile manufacturing.As more companies invest in automation, the demand for weft sensors is expected to rise substantially, driving market growth and creating significant opportunities for industry players.

Technological Advancements in Sensor Technologies

Continuous advancements in sensor technologies significantly contribute to the growth of the Weft Sensor Market Industry. Innovations such as improved accuracy, sensitivity, and response times enhance the performance and reliability of weft sensors. As technology progresses, manufacturers are able to create more sophisticated sensors that integrate seamlessly with existing systems. This results in better data collection and analysis, allowing for improved decision-making in textile manufacturing processes.Moreover, the development of wireless and IoT-enabled sensors is transforming how weft sensors are utilized in the industry, making them more appealing to manufacturers looking for modern solutions. Such technological progress is expected to stimulate market demand and open new avenues for growth within the Weft Sensor Market Industry.

Growing Focus on Quality Control in Textile Manufacturing

The growing emphasis on quality control in textile manufacturing is another prominent driver in the Weft Sensor Market Industry. Companies are increasingly prioritizing quality assurance to meet the rising standards demanded by consumers and regulatory bodies. Weft sensors play a vital role in maintaining high-quality production by detecting defects or irregularities in the fabric during the weaving process. By implementing weft sensors, manufacturers can achieve consistent quality, enhance product reliability, and ultimately improve customer satisfaction.This focus on quality control aligns with market trends that dictate the need for sustainable and defect-free manufacturing practices, further promoting the growth of the Weft Sensor Market Industry.

Weft Sensor Market Segment Insights:

Weft Sensor Market Type Insights

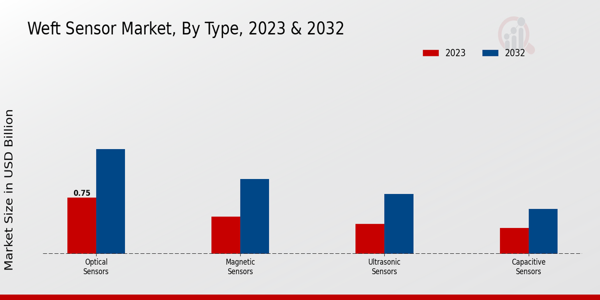

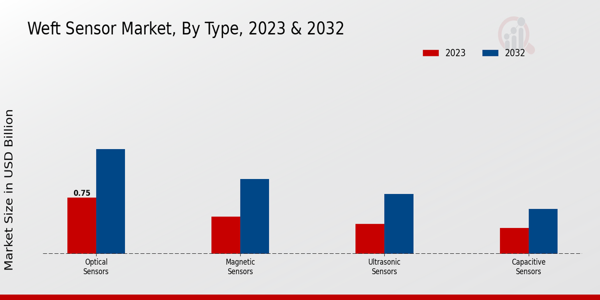

The Weft Sensor Market has been segmented into various types, notably including Optical Sensors, Magnetic Sensors, Ultrasonic Sensors and Capacitive Sensors. In 2023, the overall market is valued at 2.0 USD Billion and is projected to reach 3.8 USD Billion by 2032, reflecting a healthy growth trajectory within the industry. Among the types, Optical Sensors hold a significant position, valued at 0.75 USD Billion in 2023 and expected to reach 1.4 USD Billion by 2032. This dominance is due to the increasing demand for precise detection and monitoring in textile manufacturing, where these sensors play a crucial role in quality control and automation.Following closely, Magnetic Sensors are valued at 0.5 USD Billion in 2023, projected to grow to 1.0 USD Billion by 2032.

These sensors are especially important in applications requiring robust performance in harsh environments, making them vital in various industrial sectors. Ultrasonic Sensors, while valued at 0.4 USD Billion in 2023 with anticipated growth to 0.8 USD Billion by 2032, offer unique advantages in distance measurement and non-contact sensing, thereby finding applications in automated weaving and detection systems. Finally, Capacitive Sensors, starting at 0.35 USD Billion in 2023 and growing to 0.6 USD Billion by 2032, are significant for their high sensitivity to detecting material presence and changes in the weaving process, thus ensuring operational efficiency.The combination of these types demonstrates the diverse applications and technology advancements driving the Weft Sensor Market, showcasing how each type contributes uniquely to overall market dynamics while presenting ample opportunities for innovation and growth to meet market demands and industry challenges.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Weft Sensor Market Application Insights

Weft Sensor MarketThe textile industry plays a crucial role due to its increasing demand for quality control and efficiency in fabric production, where weft sensors are essential for maintaining yarn integrity. The automotive industry is also vital, utilizing these sensors to enhance vehicle safety and performance through real-time monitoring of materials. In aerospace, the reliance on advanced materials and strict safety standards makes weft sensors indispensable, ensuring optimal performance in complex structures.Consumer electronics exhibit a significant interest in weft sensors for their integration into various devices, enhancing functionality and user experience.

This segmentation reflects the growing need for accuracy and quality across industries, contributing to the overall growth of the Weft Sensor Market. Market trends indicate a rising focus on automation and smart technologies, further propelling demand in these vital sectors, which collectively form a dynamic landscape, presenting both challenges and opportunities for innovation. The Weft Sensor Market statistics highlight the extensive applicability and importance of these sensors in maintaining industry standards and efficiency.

Weft Sensor Market End Use Insights

Weft Sensor MarketThe division of the market highlights the critical roles of Manufacturing, Quality Control and Research and Development. Manufacturing leads as a vital area, as weft sensors are essential for streamlining production processes and ensuring precision in textile manufacturing. Quality Control also plays a crucial role, with these sensors helping to maintain high standards and reduce defects in products, thereby fostering customer satisfaction and compliance with industry standards.In the Research and Development segment, weft sensors support innovation and technology advancement, creating opportunities for developing new applications and enhancing existing ones. The growing need for automation and quality assurance across industries fuels the market growth, reinforcing the overall significance of these End Use segments in the Weft Sensor Market landscape. In summary, the demand driven by these areas underlines their importance in contributing to industry advancements and ensuring optimized performance.

Weft Sensor Market Technology Insights

Weft Sensor MarketThe market is characterized by its diverse Technology landscape, primarily categorized into Active Sensors and Passive Sensors. Active Sensors are known for their advanced capabilities in providing real-time data, thus significantly enhancing automation in various industries. Conversely, Passive Sensors predominately hold a major share, catering to cost-effective solutions with adequate performance in numerous applications.

The market growth is fueled by the increasing demand for precise monitoring and control systems, especially in textile production and smart manufacturing. However, challenges such as the integration of new technologies and maintaining sensor accuracy persist in this industry. Nonetheless, the expansion of the Internet of things (IoT) and automation solutions presents numerous opportunities for stakeholders. With an expected CAGR of 7.41 from 2024 to 2032, the Weft Sensor Market statistics highlight a robust expansion trajectory driven by continuous technological advancements and rising industrial automation.

Weft Sensor Market Regional Insights

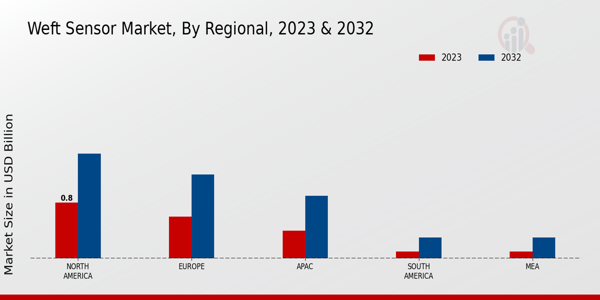

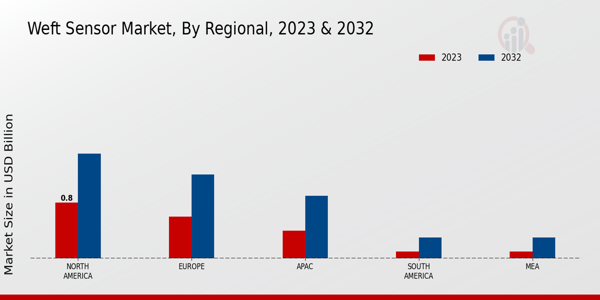

Weft Sensor MarketIn North America, the market dominates with valuations of 0.8 USD Billion in 2023, expanding to 1.5 USD Billion in 2032, reflecting its majority holding due to advanced manufacturing technologies and high demand for textile automation. Europe, valued at 0.6 USD Billion in 2023 and expected to reach 1.2 USD Billion, shows a significant growth trajectory attributed to stringent quality standards in textile production.

The APAC region, while smaller at 0.4 USD Billion in 2023, is projected to grow to 0.9 USD Billion, driven by increasing investments in textile machinery and production capabilities. South America and MEA, both at 0.1 USD Billion in 2023, are expected to reach 0.3 USD Billion by 2032, reflecting a growing interest in textile innovation, although remaining relatively minor in comparison to other regions. Collectively, these insights reveal a dynamic landscape where the Weft Sensor Market showcases varied growth potential influenced by regional manufacturing strengths and market demands.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Weft Sensor Market Key Players and Competitive Insights:

The Weft Sensor Market is experiencing a significant transformation driven by increasing demand for advanced textile technologies and innovative sensor solutions. As industries look for ways to enhance production efficiency and maintain high-quality standards, the competition within the market has intensified. Several players are vying for dominance, implementing various strategies such as technological advancements, mergers and acquisitions, and geographic expansions. The market dynamics are shaped by factors including the rising trend towards automation in textiles, the need for real-time monitoring, and the growing emphasis on sustainability and resource efficiency. Understanding the competitive landscape is essential for stakeholders aiming to navigate this evolving market and capitalize on emerging opportunities.

Schneider Electric, a prominent player in the Weft Sensor Market, has established a strong market presence through its commitment to innovation and high-quality product offerings. The company is recognized for its expertise in energy management and automation solutions, which extend seamlessly to the textile industry. Schneider Electric's strengths lie in its comprehensive portfolio of advanced sensors that enhance operational efficiency and optimize production processes. By utilizing cutting-edge technology, the company not only ensures precise measurement and monitoring but also improves overall process control within textile manufacturing. Additionally, Schneider Electric's global reach and robust distribution network allow it to cater to a diverse range of clients, enabling the company to effectively respond to varying customer needs across different regions.Keysight Technologies has carved a niche for itself within the Weft Sensor Market, leveraging its expertise in test and measurement solutions.

The company is distinguished by its focus on providing high-performance technologies that support the development and testing of weft sensors and other textile innovations. Keysight Technologies brings to the market a range of advanced solutions that optimize testing processes and ensure the reliability of sensor performance in demanding environments. These strengths enable the company to address complex challenges faced by textile manufacturers, contributing to enhanced product quality and operational efficiency. In addition, Keysight Technologies' commitment to research and development ensures a continuous flow of innovation, allowing it to stay ahead of the competition and meet the evolving needs of the textile industry.

Key Companies in the Weft Sensor Market Include:

-

Schneider Electric

-

Keysight Technologies

-

Renesas Electronics

-

Texas Instruments

-

Omron

-

Microchip Technology

-

Honeywell

-

STMicroelectronics

-

Amphenol

-

Infineon Technologies

-

TE Connectivity

-

Bosch

-

Siemens

-

ABB

-

Rockwell Automation

Weft Sensor Market Industry Developments

Recent developments in the Weft Sensor Market have indicated a growing demand driven by advancements in automation and quality control within manufacturing processes. Companies such as Schneider Electric and Siemens are innovating new weft sensors designed to enhance precision and efficiency in textile production. Meanwhile, Texas Instruments and Honeywell are actively engaging in the development of more integrated sensor solutions that incorporate IoT technologies, enabling real-time data collection and analysis. In terms of mergers and acquisitions, Omron has recently acquired a technology firm specializing in sensor integration, which is expected to bolster its market position significantly.

Likewise, Microchip Technology's acquisition of a smaller sensor manufacturer aims to enhance its product portfolio, driving growth within this sector. Additionally, there has been a notable market valuation increase for major players like STMicroelectronics and Infineon Technologies, attributed to strategic investments in R&D and enhanced production capabilities. This flourishing market environment is anticipated to impact the overall growth trajectory of the Weft Sensor Market significantly, underscoring the importance of innovation and market consolidation among leading companies.

Weft Sensor Market Segmentation Insights

-

Weft Sensor Market Type Outlook

-

Optical Sensors

-

Magnetic Sensors

-

Ultrasonic Sensors

-

Capacitive Sensors

-

Weft Sensor Market Application Outlook

-

Textile Industry

-

Automotive Industry

-

Aerospace Industry

-

Consumer Electronics

-

Weft Sensor Market End Use Outlook

-

Manufacturing

-

Quality Control

-

Research and Development

-

Weft Sensor Market Technology Outlook

-

Active Sensors

-

Passive Sensors

-

Weft Sensor Market Regional Outlook

-

North America

-

Europe

-

South America

-

Asia Pacific

-

Middle East and Africa

| Report Attribute/Metric |

Details |

| Market Size 2022 |

1.86(USD Billion) |

| Market Size 2023 |

2.0(USD Billion) |

| Market Size 2032 |

3.8(USD Billion) |

| Compound Annual Growth Rate (CAGR) |

7.41% (2024 - 2032) |

| Report Coverage |

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| Base Year |

2023 |

| Market Forecast Period |

2024 - 2032 |

| Historical Data |

2019 - 2023 |

| Market Forecast Units |

USD Billion |

| Key Companies Profiled |

Schneider Electric, Keysight Technologies, Renesas Electronics, Texas Instruments, Omron, Microchip Technology, Honeywell, STMicroelectronics, Amphenol, Infineon Technologies, TE Connectivity, Bosch, Siemens, ABB, Rockwell Automation |

| Segments Covered |

Type, Application, End Use, Technology, Regional |

| Key Market Opportunities |

Increasing demand for automation, Growth in textile manufacturing, Advancements in sensor technology, Rising need for quality control, Expansion of the smart textiles market |

| Key Market Dynamics |

Increased textile automation, Growing demand for quality control, Advancements in sensor technology, Rising industry standards, Expanding applications in manufacturing |

| Countries Covered |

North America, Europe, APAC, South America, MEA |

Frequently Asked Questions (FAQ) :

The Weft Sensor Market is expected to be valued at 3.8 USD Billion by 2032.

The expected CAGR for the Weft Sensor Market from 2024 to 2032 is 7.41%.

North America is anticipated to have the largest market share, valued at 1.5 USD Billion in 2032.

Key players in the market include Schneider Electric, Keysight Technologies, and Renesas Electronics, among others.

The Optical Sensors segment of the Weft Sensor Market is valued at 1.4 USD Billion in 2032.

In 2023, the Magnetic Sensors segment is valued at 0.5 USD Billion.

The Ultrasonic Sensors segment is expected to reach a market size of 0.8 USD Billion by 2032.

The South American market is expected to grow to 0.3 USD Billion by 2032.

The growth of the Weft Sensor Market is driven by increasing automation and demand for precision in various applications.

The Capacitive Sensors segment is projected to be valued at 0.6 USD Billion in 2032.