Summary Overview

Benchmarking of Brewing Raw Materials Market

The brewing raw materials market is undergoing significant developments driven by a range of factors including global demand for craft beers, technological advancements in brewing processes, and a focus on sustainable practices. Key raw materials in the brewing industry include barley, hops, malt, yeast, and water. Market trends reflect an increasing demand for high-quality, locally sourced ingredients as breweries seek to differentiate their products in a highly competitive market. Additionally, we address future procurement challenges and emphasize the importance of digital procurement tools in accurately forecasting market needs to keep clients ahead in this dynamic landscape. Strategic sourcing and procurement management play a crucial role in streamlining the procurement process for Benchmarking of Brewing Raw Materials development. As competition intensifies, companies are leveraging market intelligence solutions and procure analytics to optimize their supply chain management systems.

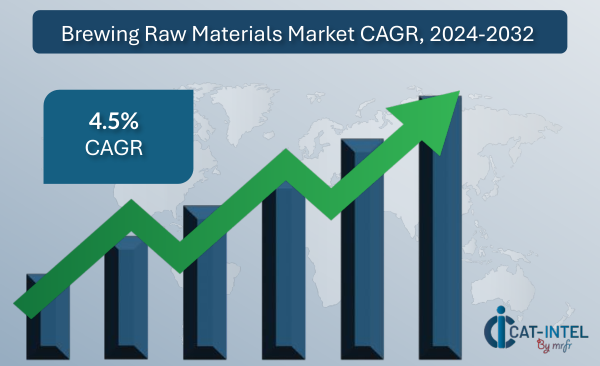

The global brewing raw materials market is projected to experience steady growth, driven by the expanding craft beer segment and increasing consumption of beer worldwide. The market is expected to grow at a Compound Annual Growth Rate (CAGR) of approximately 4.5% from 2024 to 2032, with demand for barley and hops continuing to drive the largest segment.

Key Trends and Sustainability Outlook

-

Sustainability: Breweries are focusing on more sustainable raw material sourcing, particularly in barley farming and water usage, to reduce their environmental footprint. Innovations in waste reduction, such as using leftover barley for other food products, are gaining traction. -

Craft Beer Influence: The rise of craft breweries continues to influence demand for unique and high-quality raw materials, such as special malt varieties and exotic hop strains, as brewers look to create differentiated Flavors. -

Technological Transformation and Innovations: Advances in brewing technology, including precision fermentation techniques and sustainable sourcing practices, are enhancing the quality and consistency of brewing raw materials. In addition, supplier performance management and vendor performance assessment are becoming critical for companies in this competitive landscape. -

Funding Initiatives and Regional Insights: Governments and private sectors are investing in sustainable agricultural practices and R&D for brewing technologies. While North America and Europe remain the largest markets, the Asia-Pacific region is seeing rapid growth due to the expanding beer consumption and brewery infrastructure.

Growth Drivers:

-

Increased Global Beer Consumption: The steady rise in beer consumption, particularly in emerging markets like China and India, is contributing to the rising demand for brewing raw materials. -

Consumer Preference for Craft Beer: As consumers demand more unique and locally produced beers, the market for specialized brewing raw materials continues to expand.

Overview of Market Intelligence Services for the Benchmarking of Brewing Raw material’s Market

The Brewers Association also conducts bi-annual surveys such as the Brewery Operations Benchmarking Survey (BOBS), which offers insights into how breweries are operating, including procurement strategies for raw materials. These resources provide valuable information for businesses aiming to streamline their raw material sourcing and improve operational efficiencies detailed benchmarking and market overview can help breweries make informed decisions about procurement and adapt to trends that could affect their raw material supply chain.

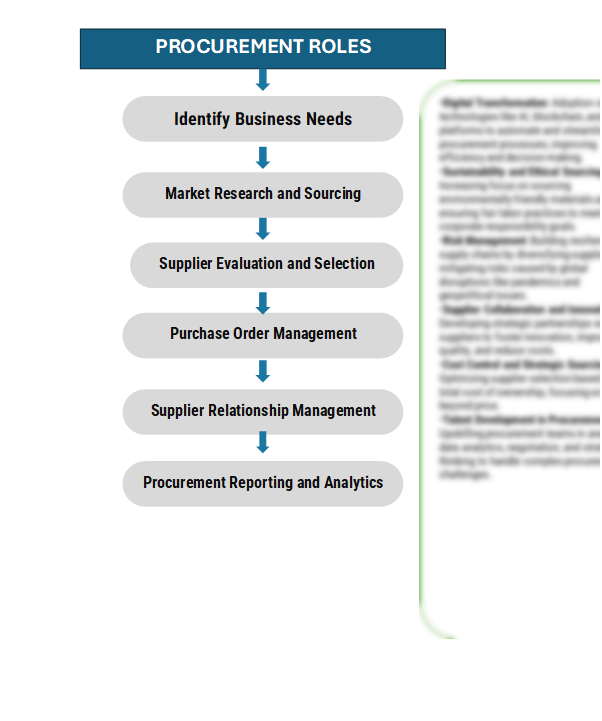

Procurement Intelligence for Benchmarking of Brewing Raw Materials market : Category Management and Strategic Sourcing"To stay ahead in the Benchmarking of Brewing Raw Materials s market, companies are optimizing procurement strategies , leveraging spend analysis solutions for vendor spend analysis , and enhancing supply chain efficiency through supply market intelligence . Procurement category management and strategic sourcing are becoming vital in achieving cost-effective procurement and ensuring timely availability of essential raw materials for vaccine production."

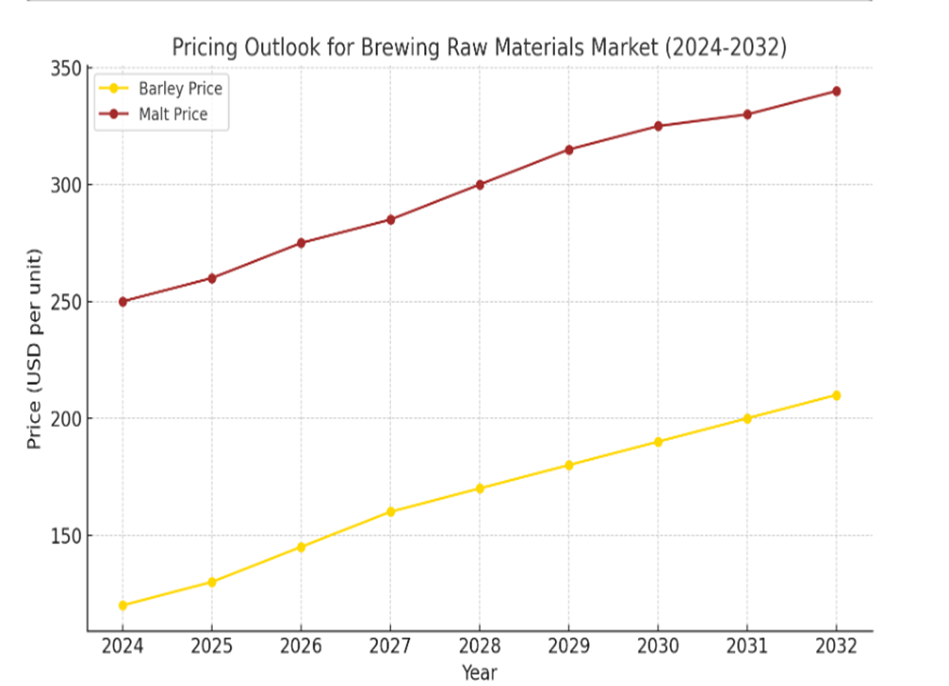

Pricing Outlook for Benchmarking of Brewing Raw Materials Market: spend analysis

The brewing raw materials market is experiencing steady growth, driven by the increasing demand for craft beer and innovative brewing ingredients. The prices of key raw materials, such as barley, hops, yeast, and water, are rising due to supply chain disruptions, adverse weather conditions, and global shifts in demand. Notably, companies like Cargill, Briess Malt & Ingredients Co., and Weyermann Specialty Malts are leading the charge in providing high-quality ingredients to meet these demands.

line chart depicting the pricing outlook for the brewing raw materials market from 2024 to 2032.

Comprehensive Price Forecast

A strong upward trend is expected, with volatility in barley and malt prices due to ongoing supply chain issues and climatic changes. However, the shift toward sustainable sourcing and localized production could stabilize costs over time. The market will continue to expand as the craft beer segment grows, alongside rising interest in specialty and organic ingredients. To manage these fluctuations, stakeholders should adopt strategic procurement practices, focusing on long-term supplier relationships and cost-optimizing technologies.

By implementing proactive procurement strategies, organizations can mitigate the impacts of rising raw material prices and secure competitive advantages in a rapidly evolving market

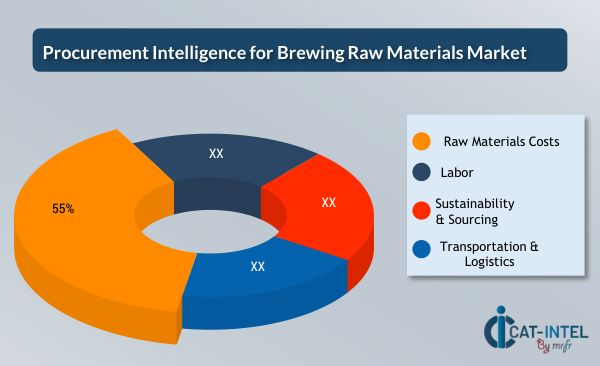

Cost Breakdown for the Benchmarking of Brewing Raw Materials: Total cost of ownership TCO and Cost saving opportunities

- Raw Materials Costs (55%)

-

Description: The brewing raw materials include malt, hops, yeast, enzymes, and various adjuncts, which are critical for flavour development, fermentation, and stabilization of the final product. -

Trends: Raw material prices are fluctuating due to global supply chain disruptions, climate change impacts, and increasing demand from the craft beer sector. For example, prices for hops and malt can be highly variable based on weather conditions and crop yields.

- Labor (XX%)

-

Description: XX -

Trends: XX

- Sustainability & Sourcing (XX%)

-

Description: XX -

Trends: XX

- Transportation & Logistics (XX%)

-

Description: XX -

Trends: X

Cost-Saving Opportunity in the Brewing Raw Materials Market: Negotiation Lever and Purchasing Negotiation Strategies

Optimizing procurement in the brewing industry can drive significant cost savings. Collaborative purchasing, where multiple breweries join forces, can reduce ingredient costs like malt and hops. This approach leverages bulk purchasing power, cutting unit prices.

Sourcing ingredients locally can reduce transportation expenses and mitigate supply chain disruptions. Additionally, switching to energy-efficient brewing processes can lower utility costs, while reducing waste and excess packaging can lead to further savings. Adopting automation and data-driven systems helps breweries optimize operations, reducing labor costs and improving efficiency. Outsourcing non-core activities, such as logistics and packaging, can also lower overhead.

Supply and Demand Overview of the Benchmarking of Brewing Raw Materials Market: Demand-Supply Dynamics and Buyer Intelligence for Effective Supplier Relationship Management (SRM)

The benchmarking of brewing raw materials market is experiencing steady growth driven by the rising demand for premium and craft beer, increased focus on sustainable sourcing, and advancements in brewing technologies. Demand is particularly high due to the need for high-quality malt, hops, yeast, and water, supported by collaborations between breweries, agricultural suppliers, and research institutions.

Demand Factors:

-

Rising Craft Beer Popularity: The increasing consumer preference for craft beers and premium brews drives higher demand for specialty ingredients like unique hops and malt varieties. -

Health-Conscious Trends: As consumers demand low-alcohol and health-oriented beer options, there is a shift towards lighter ingredients and organic options, boosting the need for such materials. -

Innovative Flavour Profiles: Breweries are constantly experimenting with new Flavors, which increases the demand for diverse and high-quality raw materials, such as specialty yeast and adjunct grains. -

Sustainability Movement: The demand for sustainable and organic ingredients is on the rise, as consumers increasingly prefer environmentally friendly products.

Supply Factors:

-

Weather Conditions & Crop Yields: The supply of brewing ingredients like hops and malt is highly dependent on weather patterns, with poor harvests leading to supply shortages and price increases. -

Technological Advances: The introduction of more efficient brewing technologies allows breweries to optimize ingredient usage, reducing waste and improving supply chain efficiency. -

Global Sourcing & Trade: Strategic partnerships and international sourcing have expanded the availability of raw materials, helping breweries meet growing demand despite local supply challenges. -

Market Competition: Competition among suppliers ensures a wider variety of ingredients and competitive pricing, but it also leads to fluctuations in availability based on demand spikes.

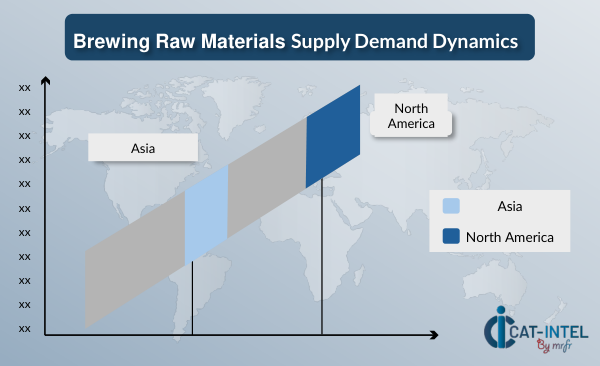

Regional Demand-Supply Outlook: Brewing Raw Materials

The image shows growing demand for brewing raw materials market in both North America and Asia, with potential price increases and increased competition.

-

North America: Dominates the brewing raw materials market, driven by:

-

Craft Breweries: A major contributor to the increasing demand for specialty ingredients, especially in the U.S., where local and artisanal brewing methods have flourished. -

Innovation in Flavors: Breweries in North America are at the forefront of experimenting with new tastes, which increases demand for specialized and high-quality raw materials. -

Sustainability Initiatives: Strong focus on eco-friendly production processes and the sourcing of sustainable ingredients, including organic grains and hops, aligns with consumer preferences for environmental responsibility. -

Global Sourcing Networks: North American breweries often collaborate with suppliers from Europe and Asia to ensure a steady supply of unique and high-quality ingredients, further driving market growth.

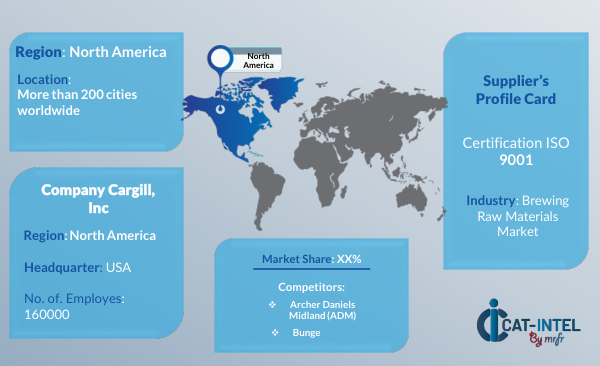

Supplier Landscape: Supplier Negotiations and Strategies

The supplier penetration in the Benchmarking of Brewing Raw Materials Market is significant, with a diverse range of global and regional players contributing to the production and distribution of essential brewing ingredients. These suppliers play a crucial role in the overall market dynamics, impacting pricing, quality, and availability of raw materials like malt, hops, yeast, and brewing adjuncts.

The market is highly competitive, with suppliers ranging from large agricultural cooperatives to specialized producers focused on organic and sustainable brewing materials.

Currently, the supplier landscape is characterized by notable consolidation among leading agribusiness companies and maltsters, which dominate the market share. However, smaller specialty suppliers and regional cooperatives are gaining traction by catering to the growing demand for craft brewing and premium ingredients tailored to unique flavour profiles.

Some of the key suppliers in the Benchmarking of Brewing Raw Materials Market include:

- Cargill, Inc.

- Malteurop Group

- BSG Craft Brewing (Brewery Supply Group)

- Yakima Chief Hops

- Boortmalt

- Hop Steiner

- Muntons Malt

- Briess Malt & Ingredients Co.

- Fermentis (Lesaffre)

- Rahr Malting Co.

Key Development: procurement category significant development

Category |

Development/Trend |

Emerging Capabilities |

|

Malt Supply |

Rising demand for craft beer boosts need for specialty malts. |

Development of malts with unique Flavors, such as caramel or smoked malts. |

|

Hops |

Increasing use of hops for distinct Flavors as craft brewers seek differentiation. |

Hops that produce enhanced aromatic qualities, including new hybrid strains. |

|

Sustainability |

Growing focus on sustainable sourcing and carbon footprint reduction in brewing. |

Introduction of energy-efficient brewing technologies, water-saving techniques. |

|

Yeast |

Innovation in yeast strains for faster fermentation and enhanced flavour profiles. |

Development of genetically modified yeast strains for better fermentation. |

Procurement Attribute/Metric |

Details |

Market Sizing |

The global brewing raw materials market is projected to grow from USD 80 billion in 2024 to USD 95 billion by 2032, with a CAGR of 4.5% (2023-2032). |

Raw Material Adoption Rate |

50% of breweries are adopting advanced sourcing strategies for hops, malt, and yeast to optimize production costs and ensure consistent quality. |

Top Procurement Strategies for 2024 |

Focus on sustainable sourcing, quality control, supplier diversification, and leveraging local suppliers to reduce transportation costs. |

Raw Material Process Automation |

40% of breweries have implemented automation in inventory management and order tracking for raw materials. |

Procurement Challenges |

Key issues include fluctuations in raw material prices, ensuring consistent quality, maintaining supplier relationships, and handling supply chain disruptions. |

Key Suppliers |

Prominent suppliers include Cargill, Malteurop, Barth Haas, Lallemand, and Weyermann, offering high-quality malt, hops, and yeast for breweries. |

Key Regions Covered |

North America, Europe, Asia-Pacific, and Latin America, with a focus on the U.S., Germany, China, and Brazil due to significant brewing industries. |

Market Drivers and Trends |

Growth driven by demand for craft beer, sustainability trends in sourcing, and innovation in brewing ingredients. Notable trends include a shift toward organic and locally sourced raw materials. |