-

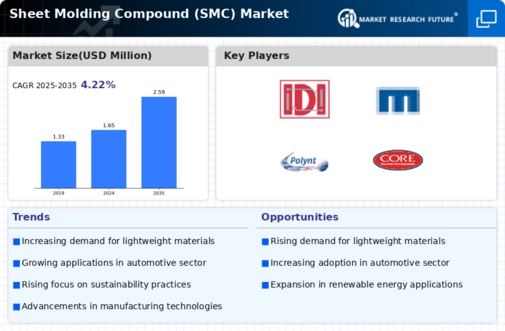

Executive Summary

-

Market Introduction

-

Definition

-

20

-

Scope of the Study 20

-

List of Assumptions 20

-

Market Structure 21

-

Key Takeaways 21

-

Market

-

Insights

-

Research Methodology

-

Research Process

-

27

-

Primary Research 28

-

Secondary Research 29

-

Market Size Estimation 29

-

Forecast Model 30

-

Market

-

Dynamics

-

Introduction 32

-

Drivers 33

- Increasing Consumption in Modern Construction Projects 34

- High cost of SMC 35

-

5.2.1

-

Rising Demand for Lightweight, Fuel-Efficient, and Electric Vehicles 33

-

5.3

-

Restraints 35

-

Opportunities

- Growing demand for automobiles in emerging economies 37

-

37

-

Challenges 38

- Problems Pertaining to the Recyclability of

-

SMC 38

-

Market Factor Analysis

-

Supply Chain Analysis

- Raw Materials 40

- SMC Producers 40

- Distributors 41

- End-Use Industries 41

-

40

-

Porter’s

- Threat of New Entrants 42

- Threat of Substitutes 42

- Bargaining Power of Buyers 42

-

Five Forces Model 41

-

6.2.2

-

Threat of Rivalry 42

-

6.2.4

-

Bargaining Power of Suppliers 42

-

Global Sheet Molding Compound Market, by Type

-

Introduction

-

44

-

Flame Resistance 46

-

Electronic Insulators 47

-

Corrosion Resistance 48

-

General Purpose 49

-

7.6

-

Others 50

-

Global Sheet Molding Compound Market, by Application

-

Introduction 52

-

Automotive 53

-

Electrical &

-

Electronics 54

-

Building & Construction 55

-

Others

-

56

-

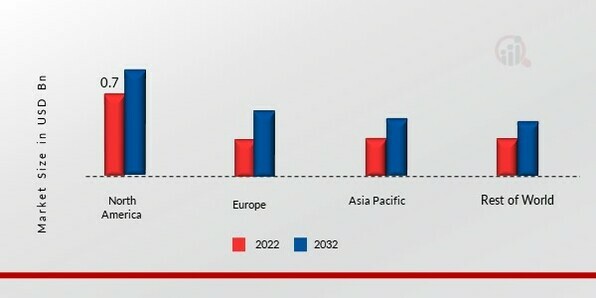

Global Sheet Molding Compound Market, by Region

-

Introduction

-

59

-

North America 62

- US 64

- Canada

-

66

-

Europe 68

- Germany 70

- France

- UK 73

- Spain 75

- Russia 77

- Rest of Europe 78

-

72

-

Asia-Pacific 80

- Japan 84

- India 86

- South

- Indonesia 89

- Australia & New Zealand

- Rest of Asia-Pacific 93

-

9.4.1

-

China 83

-

Korea 88

-

91

-

Latin America 95

- Mexico 97

- Brazil 98

- Rest of Latin America

-

100

-

The Middle East and Africa 102

- GCC 104

- South Africa 106

- Rest of Middle East and Africa 107

-

Competitive Landscape

-

Introduction 111

-

10.2

-

Recent Developments 111

-

Global Market Strategy Analysis 112

-

Company Profiles

-

IDI Composites International 114

- Company Overview 114

- Financial Overview 114

- Products Offered 114

- Key Developments 114

- Key Strategies 115

-

11.1.5

-

SWOT Analysis 115

-

Menzolit

- Company Overview 116

- Financial Overview

- Products Offered 116

- Key Developments 117

- SWOT Analysis 117

- Key Strategies 117

- Company Overview 118

- Financial Overview

- Products Offered 118

- Key Developments 120

- SWOT Analysis 120

- Key Strategies 120

- Company Overview 121

- Financial Overview 121

- Products Offered 121

- Key Developments 121

- SWOT Analysis 122

- Key Strategies 122

-

116

-

116

-

11.3

-

Polynt 118

-

118

-

11.4

-

Continental Structural Plastics Inc. 121

-

Zoltek Corporation 123

- Financial Overview 123

- Key Developments 124

- Swot

- Key Strategy 124

-

11.5.1

-

Company Overview 123

-

11.5.3

-

Products Offered 123

-

Analysis 124

-

DIC Corporation

- Company Overview 125

- Financial Overview

- Products Offered 126

- Key Developments 126

- Swot Analysis 126

- Key Strategy 126

- Company Overview 127

- Financial Overview 127

- Products Offered 127

- Key Developments 127

- Swot Analysis 127

-

125

-

125

-

11.7

-

Changzhou Tianma Group Co., Ltd 127

-

11.7.6

-

Key Strategy 127

-

Core Molding Technologies 128

- Financial Overview 128

- Key Developments 129

- Swot

- Key Strategy 129

-

11.8.1

-

Company Overview 128

-

11.8.3

-

Products Offered 128

-

Analysis 129

-

Zhejiang Sida New

- 1.5.1Company Overview 130

- Products Offered 130

- SWOT Analysis 130

- Key Strategies

-

Materials Co., Ltd 130

-

11.9.2

-

Financial Overview 130

-

11.9.4

-

Key Developments 130

-

130

-

Molymer SSP Co. Ltd 131

- Company Overview

- Financial Overview 131

- Products Offered

- Key Developments 131

- SWOT Analysis 131

- Key Strategy 131

-

131

-

131

-

Showa Denko K.K. 132

- Company Overview 132

- Financial Overview 132

- Products Offered 132

- Key Developments 133

- SWOT Analysis 133

- Key Strategies 133

- Company Overview 134

- Financial Overview 134

- Products Offered 134

- Key Developments 134

- SWOT Analysis 134

-

11.12

-

Devi Polymers Private Limited 134

-

11.12.6

-

Key Strategies 134

-

Zhejiang Yueqing SMC & BMC Manufacture Factory

- Company Overview 135

- Financial Overview

- Products Offered 135

- Key Developments

- SWOT Analysis 135

- Key Strategies 135

-

135

-

135

-

135

-

Changzhou City Jiangshi Composite Technology Co., Ltd 136

- Company Overview 136

- Financial Overview 136

- Products Offered 136

- Key Developments 136

- Key Strategy 136

-

Huayuan Advanced Materials Co., Ltd

- Company Overview 137

- Financial Overview

- Products Offered 137

- Key Developments

- SWOT Analysis 138

- Key Strategies 138

-

137

-

137

-

137

-

Jiangsu Zhaojun New Material Co., Ltd 139

- Company

- Financial Overview 139

- Products

- Key Developments 139

- SWOT Analysis

- Key Strategy 139

-

Overview 139

-

Offered 139

-

139

-

Beijing New Friend Insulation

- Company Overview 140

- Products Offerings 140

- SWOT Analysis 140

- Key

-

Material Co., Ltd 140

-

11.17.2

-

Financial Overview 140

-

11.17.4

-

Key Developments 140

-

Strategies 140

-

Zhejiang Sida New Materials Co., Ltd 141

- Company Overview 141

- Financial Overview 141

- Products Offered 141

- 1.5.4Key Developments 141

- SWOT Analysis 141

- Key Strategies 141

-

12

-

Conclusion

-

Key Findings 143

-

List of Tables

-

MARKET SYNOPSIS 18

-

LIST OF ASSUMPTIONS 20

-

+GLOBAL SHEET MOLDING COMPOUND, BY TYPE, 2023-2032(USD MILLION) 44

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS)

-

45

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR FLAME RESISTANCE,

-

BY REGION, 2023-2032(USD MILLION) 46

-

GLOBAL SHEET MOLDING COMPOUND

-

MARKET FOR FLAME RESISTANCE, BY REGION, 2023-2032(KILOTONS) 46

-

TABLE

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR ELECTRONIC INSULATORS, BY REGION, 2023-2032(USD

-

MILLION) 47

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR ELECTRONIC

-

INSULATORS, BY REGION, 2023-2032(KILOTONS) 47

-

GLOBAL SHEET MOLDING

-

COMPOUND MARKET FOR CORROSION RESISTANCE, BY REGION, 2023-2032(USD MILLION) 48

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR CORROSION RESISTANCE,

-

BY REGION, 2023-2032(KILOTONS) 48

-

GLOBAL SHEET MOLDING COMPOUND

-

MARKET FOR GENERAL PURPOSE, BY REGION, 2023-2032(USD MILLION) 49

-

TABLE

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR GENERAL PURPOSE, BY REGION, 2023-2032(KILOTONS)

-

49

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR OTHERS, BY REGION,

-

GLOBAL SHEET MOLDING COMPOUND MARKET

-

FOR OTHERS, BY REGION, 2023-2032(KILOTONS) 50

-

GLOBAL SHEET MOLDING

-

COMPOUND, BY APPLICATION, 2023-2032(USD MILLION) 52

-

GLOBAL SHEET

-

MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 53

-

TABLE

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR AUTOMOTIVE, BY REGION, 2023-2032(USD

-

MILLION) 53

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR AUTOMOTIVE,

-

BY REGION, 2023-2032(KILOTONS) 54

-

GLOBAL SHEET MOLDING COMPOUNDMARKET

-

FOR ELECTRICAL & ELECTRONICS, BY REGION, 2023-2032(USD MILLION) 54

-

GLOBAL SHEET MOLDING COMPOUND MARKET FOR ELECTRICAL & ELECTRONICS,

-

BY REGION, 2023-2032(KILOTONS) 55

-

GLOBAL SHEET MOLDING COMPOUND

-

MARKET FOR BUILDING & CONSTRUCTION, BY REGION, 2023-2032(USD MILLION) 55

-

GLOBAL SHEET MOLDING COMPOUNDMARKET FOR BUILDING & CONSTRUCTION,

-

BY REGION, 2023-2032(KILOTONS) 56

-

GLOBAL SHEET MOLDING COMPOUND

-

MARKET FOR OTHERS, BY REGION, 2023-2032(USD MILLION) 56

-

GLOBAL

-

SHEET MOLDING COMPOUND MARKET FOR OTHERS, BY REGION, 2023-2032(KILOTONS) 57

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY REGION, 2023-2032(USD MILLION)

-

59

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY REGION, 2023-2032(KILOTONS)

-

60

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(

-

USD MILLION) 61

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY TYPE,

-

GLOBAL SHEET MOLDING COMPOUND MARKET,

-

BY APPLICATION, 2023-2032( USD MILLION) 62

-

GLOBAL SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 62

-

NORTH

-

AMERICA SHEET MOLDING COMPOUND MARKET, BY COUNTRY, 2023-2032(USD MILLION) 62

-

NORTH AMERICA SHEET MOLDING COMPOUNDMARKET, BY COUNTRY, 2023-2032(KILOTONS)

-

63

-

NORTH AMERICA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(

-

USD MILLION) 63

-

NORTH AMERICA SHEET MOLDING COMPOUND MARKET,

-

BY TYPE, 2023-2032(KILOTONS) 63

-

NORTH AMERICA SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 64

-

NORTH

-

AMERICA SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 64

-

US SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032( USD MILLION)

-

64

-

US SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS)

-

65

-

US SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 65

-

US SHEET MOLDING COMPOUNDMARKET, BY APPLICATION,

-

CANADA SHEET MOLDING COMPOUND MARKET,

-

BY TYPE, 2023-2032( USD MILLION) 66

-

CANADA SHEET MOLDING COMPOUND

-

MARKET, BY TYPE, 2023-2032(KILOTONS) 67

-

CANADA SHEET MOLDING

-

COMPOUNDMARKET, BY APPLICATION, 2023-2032(USD MILLION) 67

-

CANADA

-

SHEET MOLDING COMPOUNDMARKET, BY APPLICATION, 2023-2032(KILOTONS) 67

-

TABLE

-

EUROPE SHEET MOLDING COMPOUND MARKET, BY COUNTRY, 2023-2032(USD MILLION) 68

-

EUROPE SHEET MOLDING COMPOUND MARKET, BY COUNTRY, 2023-2032(KILOTONS)

-

68

-

EUROPE SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(

-

USD MILLION) 69

-

EUROPE SHEET MOLDING COMPOUND MARKET, BY TYPE,

-

EUROPE SHEET MOLDING COMPOUND MARKET,

-

BY APPLICATION, 2023-2032(USD MILLION) 69

-

EUROPE SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 70

-

GERMANY

-

SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032( USD MILLION) 70

-

TABLE

-

GERMANY SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 71

-

GERMANY SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 71

-

GERMANY SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

FRANCE SHEET MOLDING COMPOUND MARKET,

-

BY TYPE, 2023-2032( USD MILLION) 72

-

FRANCE SHEET MOLDING COMPOUND

-

MARKET, BY TYPE, 2023-2032(KILOTONS) 72

-

FRANCE SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 73

-

FRANCE

-

SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 73

-

TABLE

-

UK SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032( USD MILLION) 73

-

UK SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 74

-

UK SHEET MOLDING COMPOUNDMARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 74

-

UK SHEET MOLDING COMPOUNDMARKET, BY APPLICATION,

-

SPAIN SHEET MOLDING COMPOUND MARKET,

-

BY TYPE, 2023-2032( USD MILLION) 75

-

SPAIN SHEET MOLDING COMPOUND

-

MARKET, BY TYPE, 2023-2032(KILOTONS) 76

-

SPAIN SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 76

-

SPAIN

-

SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 76

-

TABLE

-

RUSSIA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032( USD MILLION) 77

-

RUSSIA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS)

-

77

-

RUSSIA SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 78

-

RUSSIA SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

REST OF EUROPE SHEET MOLDING COMPOUND

-

MARKET, BY TYPE, 2023-2032( USD MILLION) 78

-

REST OF EUROPE SHEET

-

MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 79

-

REST

-

OF EUROPE SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION)

-

79

-

REST OF EUROPE SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

ASIA-PACIFIC SHEET MOLDING COMPOUND MARKET,

-

BY COUNTRY, 2023-2032(USD MILLION) 80

-

ASIA-PACIFIC SHEET MOLDING

-

COMPOUND MARKET, BY COUNTRY, 2023-2032(KILOTONS) 81

-

ASIA-PACIFIC

-

SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD MILLION) 81

-

TABLE

-

ASIA-PACIFIC SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 82

-

ASIA-PACIFIC SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 82

-

ASIA-PACIFIC SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

CHINA SHEET MOLDING COMPOUND MARKET,

-

BY TYPE, 2023-2032( USD MILLION) 83

-

CHINA SHEET MOLDING COMPOUND

-

MARKET, BY TYPE, 2023-2032(KILOTONS) 83

-

CHINA SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 84

-

CHINA

-

SHEET MOLDING COMPOUNDMARKET, BY APPLICATION, 2023-2032(KILOTONS) 84

-

TABLE

-

JAPAN SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD MILLION) 84

-

JAPAN SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 85

-

JAPAN SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 85

-

JAPAN SHEET MOLDING COMPOUNDMARKET, BY APPLICATION,

-

INDIA SHEET MOLDING COMPOUND MARKET,

-

BY TYPE, 2023-2032(USD MILLION) 86

-

INDIA SHEET MOLDING COMPOUND

-

MARKET, BY TYPE, 2023-2032(KILOTONS) 87

-

INDIA SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 87

-

INDIA

-

SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 87

-

TABLE

-

SOUTH KOREA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032( USD MILLION) 88

-

SOUTH KOREA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS)

-

88

-

SOUTH KOREA SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

SOUTH KOREA SHEET MOLDING COMPOUND

-

MARKET, BY APPLICATION, 2023-2032(KILOTONS) 89

-

INDONESIA SHEET

-

MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD MILLION) 89

-

TABLE 98

-

INDONESIA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 90

-

INDONESIA SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 90

-

INDONESIA SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

AUSTRALIA & NEW ZEALAND SHEET MOLDING

-

COMPOUND MARKET, BY TYPE, 2023-2032(USD MILLION) 91

-

AUSTRALIA

-

& NEW ZEALAND SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 92

-

AUSTRALIA & NEW ZEALAND SHEET MOLDING COMPOUND MARKET, BY

-

APPLICATION, 2023-2032(USD MILLION) 92

-

AUSTRALIA & NEW

-

ZEALAND SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 92

-

REST OF ASIA-PACIFIC SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD

-

MILLION) 93

-

REST OF ASIA-PACIFIC SHEET MOLDING COMPOUND MARKET,

-

BY TYPE, 2023-2032(KILOTONS) 93

-

REST OF ASIA-PACIFIC SHEET

-

MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 94

-

TABLE

-

REST OF ASIA-PACIFIC SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS)

-

94

-

LATIN AMERICA SHEET MOLDING COMPOUND MARKET, BY COUNTRY,

-

LATIN AMERICA SHEET MOLDING COMPOUND

-

MARKET, BY COUNTRY, 2023-2032(KILOTONS) 95

-

LATIN AMERICA SHEET

-

MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD MILLION) 95

-

TABLE 112

-

LATIN AMERICA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 96

-

LATIN AMERICA SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 96

-

LATIN AMERICA SHEET MOLDING COMPOUND MARKET, BY

-

APPLICATION, 2023-2032(KILOTONS) 96

-

MEXICO SHEET MOLDING COMPOUND

-

MARKET, BY TYPE, 2023-2032(USD MILLION) 97

-

MEXICO SHEET MOLDING

-

COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 97

-

MEXICO SHEET

-

MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 98

-

TABLE

-

MEXICO SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 98

-

BRAZIL SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD MILLION)

-

98

-

BRAZIL SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS)

-

99

-

BRAZIL SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 99

-

BRAZIL SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

REST OF LATIN AMERICA SHEET MOLDING

-

COMPOUND MARKET, BY TYPE, 2023-2032( USD MILLION) 100

-

REST

-

OF LATIN AMERICA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 101

-

REST OF LATIN AMERICA SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

REST OF LATIN AMERICA SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 101

-

THE

-

MIDDLE EAST AND AFRICA SHEET MOLDING COMPOUND MARKET, BY COUNTRY, 2023-2032(USD

-

MILLION) 102

-

THE MIDDLE EAST AND AFRICA SHEET MOLDING COMPOUND

-

MARKET, BY COUNTRY, 2023-2032(KILOTONS) 102

-

THE MIDDLE EAST

-

AND AFRICA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD MILLION) 103

-

THE MIDDLE EAST AND AFRICA SHEET MOLDING COMPOUND MARKET, BY TYPE,

-

THE MIDDLE EAST AND AFRICA SHEET MOLDING

-

COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 103

-

TABLE 132

-

THE MIDDLE EAST AND AFRICA SHEET MOLDING COMPOUNDMARKET, BY APPLICATION, 2023-2032(KILOTONS)

-

104

-

GCC SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD

-

MILLION) 104

-

GCC SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS)

-

105

-

GCC SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 105

-

GCC SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

SOUTH AFRICA SHEET MOLDING COMPOUND

-

MARKET, BY TYPE, 2023-2032(USD MILLION) 106

-

SOUTH AFRICA. SHEET

-

MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 106

-

SOUTH

-

AFRICA SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD MILLION) 107

-

SOUTH AFRICA SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS)

-

107

-

REST OF MIDDLE EAST AND AFRICA SHEET MOLDING COMPOUND MARKET,

-

BY TYPE, 2023-2032(USD MILLION) 107

-

REST OF MIDDLE EAST AND

-

AFRICA SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 108

-

REST OF MIDDLE EAST AND AFRICA SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

REST OF MIDDLE EAST AND AFRICA SHEET

-

MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(KILOTONS) 109

-

TABLE

-

KEY DEVELOPMENTS 111

-

-

List

-

of Figures

-

GLOBAL SHEET MOLDING COMPOUND MARKET: MARKET STRUCTURE

-

21

-

KEY TAKEAWAYS OF THE SHEET MOLDING COMPOUND MARKET 21

-

NORTH AMERICA MARKET SIZE & MARKET SHARE BY COUNTRY (2020)

-

23

-

EUROPE MARKET SIZE & MARKET SHARE BY COUNTRY (2020) 23

-

ASIA-PACIFIC & MARKET SHARE BY COUNTRY (2020) 24

-

FIGURE

-

LATIN AMERICA MARKET SIZE & MARKET SHARE BY COUNTRY (2020) 24

-

FIGURE

-

MIDDLE EAST & AFRICA MARKET SIZE & MARKET SHARE BY COUNTRY (2020) 25

-

SHEET MOLDING COMPOUND MARKET, BY REGION, 2017 25

-

FIGURE

-

RESEARCH PROCESS OF MRFR 27

-

TOP-DOWN AND BOTTOM-UP APPROACH

-

30

-

MARKET DYNAMICS OVERVIEW 32

-

GLOBAL

-

LIGHT VEHICLE SALES (MILLION UNITS) 34

-

DRIVERS IMPACT ANALYSIS

-

35

-

COST COMPARISON, 2016 (USD/KG) 36

-

RESTRAINTS

-

IMPACT ANALYSIS 36

-

GLOBAL AUTOMOTIVE PRODUCTION (MILLION UNITS)

-

37

-

SUPPLY CHAIN ANALYSIS 40

-

PORTER'S FIVE

-

FORCES ANALYSIS OF THE GLOBAL SHEET MOLDING COMPOUND (SMC) MARKET 41

-

FIGURE

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(USD MILLION) 44

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY TYPE, 2023-2032(KILOTONS) 45

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY APPLICATION, 2023-2032(USD

-

MILLION) 52

-

GLOBAL SHEET MOLDING COMPOUND MARKET, BY APPLICATION,

-

GLOBAL SHEET MOLDING COMPOUND MARKET

-

BY REGION, 2023-2032(USD MILLION) 59

-

GLOBAL SHEET MOLDING COMPOUND

-

MARKET BY REGION, 2023-2032(KILOTONS) 60

Leave a Comment