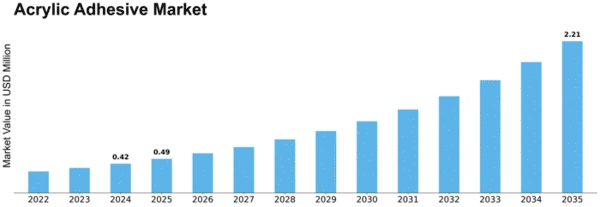

Acrylic Adhesive Size

Acrylic Adhesive Market Growth Projections and Opportunities

The worldwide acrylic adhesives market is set to grow steadily in the coming years, primarily due to the increasing demand from various industries like automotive, construction, electronics, and packaging. Acrylic adhesives are popular because they possess excellent properties, including strong bonding, resistance to temperature and chemicals, and outstanding durability.

This market is marked by the presence of key players such as Henkel AG & Co. KGaA, 3M Company, and H.B. Fuller Company. These companies are actively engaged in product innovation, strategic partnerships, and mergers and acquisitions to fortify their positions in the market and broaden their range of products.

As of 2022, the global acrylic adhesives market was valued at USD 8,406.2 million, and it is anticipated to reach USD 12,411.0 million by 2030. This growth is expected to follow a Compound Annual Growth Rate (CAGR) of 5.25% over the forecast period. The geographical distribution of this market shows that Asia-Pacific holds the largest market share at 35.70%, followed by Europe at 30.89%, and North America at 25.46%. Looking ahead, Asia Pacific is projected to experience the highest CAGR at 5.74% from 2023 to 2030.

The key driving forces behind this anticipated growth include the versatile application of acrylic adhesives in crucial industries. In the automotive sector, these adhesives are used for bonding various components, ensuring strength and stability in vehicle structures. Construction relies on acrylic adhesives for their ability to provide robust bonding in different materials, contributing to the durability of structures. The electronics industry benefits from these adhesives due to their resistance to temperature and chemicals, crucial for securing delicate electronic components. Additionally, the packaging industry utilizes acrylic adhesives for sealing and bonding packaging materials, ensuring the integrity of the packaged goods.

Noteworthy players in the market, such as Henkel, 3M, and H.B. Fuller, are actively contributing to this growth through continuous innovation. They are investing in developing new products and technologies to meet the evolving needs of various industries. Furthermore, strategic partnerships allow these companies to combine their strengths and resources to explore new opportunities and enhance their market presence.

The projected CAGR of 5.25% indicates a steady and sustained growth trajectory for the acrylic adhesives market. The increasing demand from key industries and the proactive strategies adopted by major players are poised to drive this growth, making acrylic adhesives a crucial component in various industrial applications. As the market expands, the emphasis on innovation and collaboration will likely continue, ensuring that acrylic adhesives remain at the forefront of bonding and sealing solutions across diverse sectors.

Leave a Comment