Top Industry Leaders in the Acrylic Based Elastomers Market

These versatile synthetic rubbers, prized for their heat and oil resistance, find applications in diverse sectors, from automotive gaskets to medical tubing. But beneath the surface of elasticity lies a competitive landscape buzzing with innovation and strategic maneuvers.

These versatile synthetic rubbers, prized for their heat and oil resistance, find applications in diverse sectors, from automotive gaskets to medical tubing. But beneath the surface of elasticity lies a competitive landscape buzzing with innovation and strategic maneuvers.

Stretching Beyond Limits: Strategies Shaping the Market:

-

Product Diversification: Leading players like Arkema, Evonik, and Dow Chemical are pushing the boundaries with new acrylic elastomer formulations offering enhanced flame retardancy, improved low-temperature performance, and compatibility with specific solvents. -

Vertical Integration: Securing a reliable supply of key raw materials like alkyl acrylates is crucial. Companies like Asahi Kasei and Lanxess are investing in backward integration to gain control over supply chains and optimize costs. -

Focus on Sustainability: Environmental concerns are shaping the market. Players are adopting greener production processes, using renewable feedstocks, and developing readily recyclable acrylic elastomers to meet sustainability goals. -

Geographic Expansion: Emerging markets in Asia and Africa present immense growth potential. Companies like Jilin Chemical and LG Chem are establishing production facilities and forging partnerships in these regions to capitalize on the rising demand.

Factors Influencing Market Share: The Tug-of-War:

-

Automotive Demand: The automotive industry remains the primary driver, with acrylic elastomers finding use in seals, hoses, and vibration dampers. Fuel efficiency regulations and the shift towards electric vehicles are influencing material choices, presenting both challenges and opportunities. -

Price Volatility: Crude oil, a key precursor for acrylic esters, is susceptible to price swings, impacting production costs and profitability. Players with robust hedging strategies and diversified customer bases can weather such fluctuations. -

Regulatory Landscape: Stringent regulations on chemical safety and environmental impact, like REACH in Europe and TSCA in the US, are shaping the market. Companies with compliant and eco-friendly formulations gain a competitive edge. -

Technological Advancements: The development of new processing techniques and functional additives is leading to improved performance and cost-effectiveness of acrylic elastomers. Early adopters and innovators stand to benefit significantly.

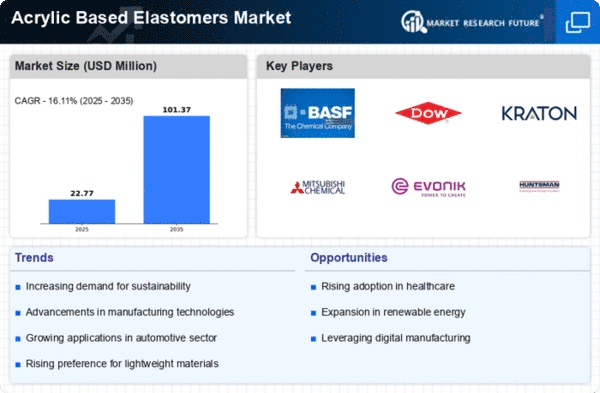

Key Players:

Key players of the Global Acrylic Based Elastomers are

- DuPont (U.S.)

- BASF SE (Germany)

- Dow Chemical Company (U.S.)

- H.B. Fuller (U.S.)

- Eastman Chemical Company (U.S.)

- ExxonMobil Corporation (U.S.)

- ARKEMA (France)

Recent Developments

-

September 2023: A fire at a major acrylic ester production facility in the US disrupts global supply chains, leading to temporary shortages and price hikes for acrylic elastomers. -

October 2023: The European Commission proposes stricter regulations on certain chemicals used in the production of acrylic elastomers, prompting a shift towards alternative formulations. -

November 2023: A consortium of leading academic institutions and industry players launches a collaborative research project to develop next-generation acrylic elastomers with superior chemical resistance for use in harsh environments. -

December 2023: The acrylic elastomers market shows signs of recovery following a period of price volatility, with cautious optimism for steady growth in 2024.