Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

On-Premise

Cloud

Hybrid

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

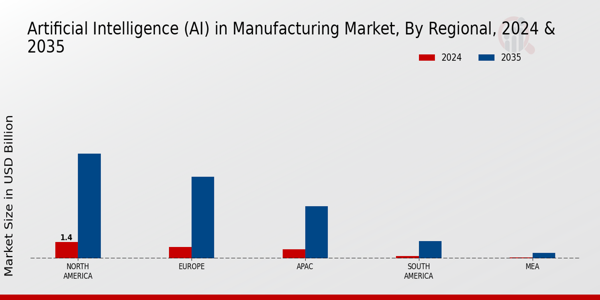

North America

Europe

South America

Asia Pacific

Middle East and Africa

North America Outlook (USD Billion, 2019-2035)

North America Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

North America Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

North America Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

North America Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

North America Artificial Intelligence (AI) in Manufacturing Market by Regional Type

US

Canada

US Outlook (USD Billion, 2019-2035)

US Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

US Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

US Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

US Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

CANADA Outlook (USD Billion, 2019-2035)

CANADA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

CANADA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

CANADA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

CANADA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

Europe Outlook (USD Billion, 2019-2035)

Europe Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

Europe Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

Europe Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

Europe Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

Europe Artificial Intelligence (AI) in Manufacturing Market by Regional Type

Germany

UK

France

Russia

Italy

Spain

Rest of Europe

GERMANY Outlook (USD Billion, 2019-2035)

GERMANY Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

GERMANY Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

GERMANY Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

GERMANY Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

UK Outlook (USD Billion, 2019-2035)

UK Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

UK Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

UK Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

UK Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

FRANCE Outlook (USD Billion, 2019-2035)

FRANCE Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

FRANCE Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

FRANCE Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

FRANCE Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

RUSSIA Outlook (USD Billion, 2019-2035)

RUSSIA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

RUSSIA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

RUSSIA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

RUSSIA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

ITALY Outlook (USD Billion, 2019-2035)

ITALY Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

ITALY Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

ITALY Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

ITALY Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

SPAIN Outlook (USD Billion, 2019-2035)

SPAIN Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

SPAIN Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

SPAIN Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

SPAIN Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

REST OF EUROPE Outlook (USD Billion, 2019-2035)

REST OF EUROPE Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

REST OF EUROPE Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

REST OF EUROPE Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

REST OF EUROPE Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

APAC Outlook (USD Billion, 2019-2035)

APAC Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

APAC Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

APAC Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

APAC Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

APAC Artificial Intelligence (AI) in Manufacturing Market by Regional Type

China

India

Japan

South Korea

Malaysia

Thailand

Indonesia

Rest of APAC

CHINA Outlook (USD Billion, 2019-2035)

CHINA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

CHINA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

CHINA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

CHINA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

INDIA Outlook (USD Billion, 2019-2035)

INDIA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

INDIA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

INDIA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

INDIA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

JAPAN Outlook (USD Billion, 2019-2035)

JAPAN Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

JAPAN Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

JAPAN Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

JAPAN Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

SOUTH KOREA Outlook (USD Billion, 2019-2035)

SOUTH KOREA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

SOUTH KOREA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

SOUTH KOREA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

SOUTH KOREA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

MALAYSIA Outlook (USD Billion, 2019-2035)

MALAYSIA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

MALAYSIA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

MALAYSIA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

MALAYSIA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

THAILAND Outlook (USD Billion, 2019-2035)

THAILAND Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

THAILAND Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

THAILAND Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

THAILAND Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

INDONESIA Outlook (USD Billion, 2019-2035)

INDONESIA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

INDONESIA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

INDONESIA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

INDONESIA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

REST OF APAC Outlook (USD Billion, 2019-2035)

REST OF APAC Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

REST OF APAC Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

REST OF APAC Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

REST OF APAC Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

South America Outlook (USD Billion, 2019-2035)

South America Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

South America Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

South America Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

South America Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

South America Artificial Intelligence (AI) in Manufacturing Market by Regional Type

Brazil

Mexico

Argentina

Rest of South America

BRAZIL Outlook (USD Billion, 2019-2035)

BRAZIL Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

BRAZIL Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

BRAZIL Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

BRAZIL Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

MEXICO Outlook (USD Billion, 2019-2035)

MEXICO Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

MEXICO Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

MEXICO Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

MEXICO Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

ARGENTINA Outlook (USD Billion, 2019-2035)

ARGENTINA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

ARGENTINA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

ARGENTINA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

ARGENTINA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

REST OF SOUTH AMERICA Outlook (USD Billion, 2019-2035)

REST OF SOUTH AMERICA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

REST OF SOUTH AMERICA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

REST OF SOUTH AMERICA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

REST OF SOUTH AMERICA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

MEA Outlook (USD Billion, 2019-2035)

MEA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

MEA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

MEA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

MEA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

MEA Artificial Intelligence (AI) in Manufacturing Market by Regional Type

GCC Countries

South Africa

Rest of MEA

GCC COUNTRIES Outlook (USD Billion, 2019-2035)

GCC COUNTRIES Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

GCC COUNTRIES Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

GCC COUNTRIES Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

GCC COUNTRIES Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

SOUTH AFRICA Outlook (USD Billion, 2019-2035)

SOUTH AFRICA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

SOUTH AFRICA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

SOUTH AFRICA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

SOUTH AFRICA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

REST OF MEA Outlook (USD Billion, 2019-2035)

REST OF MEA Artificial Intelligence (AI) in Manufacturing Market by Application Type

Predictive Maintenance

Quality Control

Supply Chain Management

Robotics

Production Planning

REST OF MEA Artificial Intelligence (AI) in Manufacturing Market by Technology Type

Machine Learning

Natural Language Processing

Computer Vision

Robotic Process Automation

Deep Learning

REST OF MEA Artificial Intelligence (AI) in Manufacturing Market by Deployment Type

On-Premise

Cloud

Hybrid

REST OF MEA Artificial Intelligence (AI) in Manufacturing Market by End Use Industry Type

Automotive

Electronics

Aerospace

Food and Beverage

Pharmaceuticals

Leave a Comment