Automotive Airbag Fabric Market Summary

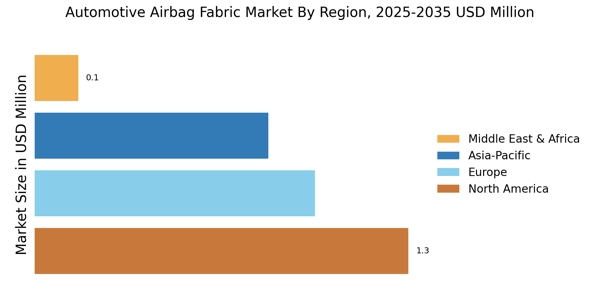

As per Market Research Future analysis, the Automotive Airbag Fabric Market Size was estimated at 3.19 USD Million in 2024. The Automotive Airbag Fabric industry is projected to grow from USD 3.365 Million in 2025 to USD 5.744 Million by 2035, exhibiting a compound annual growth rate (CAGR) of 5.49% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The Automotive Airbag Fabric Market is poised for growth driven by technological advancements and increasing safety regulations.

- Technological advancements in fabric production are enhancing the performance and safety of automotive airbags.

- Sustainability initiatives are becoming increasingly important, influencing material choices in airbag fabric manufacturing.

- The integration of smart technologies is expected to revolutionize airbag systems, particularly in North America.

- Rising consumer awareness of safety features and increasing vehicle safety regulations are key drivers propelling market growth.

Market Size & Forecast

| 2024 Market Size | 3.19 (USD Million) |

| 2035 Market Size | 5.744 (USD Million) |

| CAGR (2025 - 2035) | 5.49% |

Major Players

Takata Corporation (JP), Autoliv Inc. (SE), Zhejiang Gohigh Technology Co., Ltd. (CN), Hyosung Corporation (KR), Teijin Limited (JP), Milliken & Company (US), Ahlstrom-Munksjö (FI), Jiangsu Kelong Chemical Fiber Co., Ltd. (CN)