- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

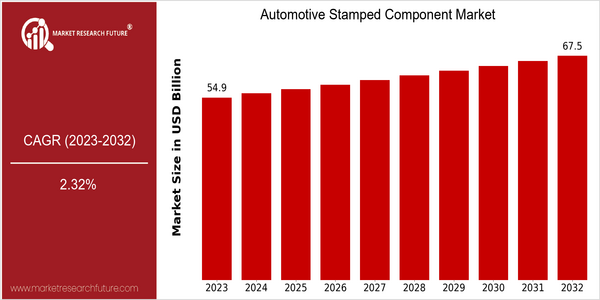

| Year | Value |

|---|---|

| 2023 | USD 54.91 Billion |

| 2032 | USD 67.5 Billion |

| CAGR (2024-2032) | 2.32 % |

Note – Market size depicts the revenue generated over the financial year

The global automotive stamped component market is currently valued at approximately USD 54.91 billion in 2023 and is projected to reach USD 67.5 billion by 2032, reflecting a compound annual growth rate (CAGR) of 2.32% from 2024 to 2032. This steady growth trajectory indicates a resilient demand for stamped components, which are essential in the manufacturing of various automotive parts, including body panels, structural components, and chassis parts. The market's expansion can be attributed to the increasing production of vehicles, particularly in emerging economies, alongside the growing trend towards lightweight materials that enhance fuel efficiency and reduce emissions. Several factors are driving this market growth, including advancements in stamping technologies, such as progressive die stamping and hydroforming, which improve production efficiency and reduce waste. Additionally, the rising adoption of electric vehicles (EVs) is creating new opportunities for stamped components, as manufacturers seek to optimize designs for battery enclosures and lightweight structures. Key players in the automotive stamped component market, such as Magna International, Gestamp Automoción, and Aisin Seiki, are actively engaging in strategic initiatives, including partnerships and investments in innovative manufacturing processes, to enhance their competitive edge and meet the evolving demands of the automotive industry.

Regional Market Size

Regional Deep Dive

The Automotive Stamped Component Market is experiencing significant dynamics across various regions, driven by the increasing demand for lightweight materials, advancements in manufacturing technologies, and a growing focus on sustainability. Each region exhibits unique characteristics influenced by local automotive production rates, regulatory frameworks, and consumer preferences. The market is poised for growth as manufacturers adapt to evolving trends such as electric vehicle production and the integration of smart technologies in vehicles.

Europe

- Europe is at the forefront of adopting sustainable manufacturing practices, with initiatives such as the European Green Deal encouraging automotive manufacturers to utilize recycled materials in stamped components, thereby reducing environmental impact.

- Key players like Volkswagen and BMW are investing in advanced stamping technologies, including automation and robotics, to improve production efficiency and meet the growing demand for high-quality stamped components in their electric vehicle lineups.

Asia Pacific

- The Asia-Pacific region, particularly countries like China and Japan, is experiencing rapid growth in the automotive stamped component market, driven by the increasing production of passenger vehicles and a strong focus on technological advancements in manufacturing.

- Government initiatives in China, such as the Made in China 2025 plan, are promoting the adoption of high-tech manufacturing processes, which is expected to enhance the quality and efficiency of stamped components in the automotive sector.

Latin America

- Latin America is seeing a gradual increase in automotive stamped component production, particularly in Brazil and Mexico, where local manufacturers are adapting to the needs of global automotive companies looking to establish production facilities in the region.

- The region's automotive industry is benefiting from trade agreements such as the USMCA, which are facilitating cross-border trade and encouraging investments in advanced stamping technologies to meet the demands of the North American market.

North America

- The North American automotive stamped component market is witnessing a surge in demand due to the rise of electric vehicles (EVs), with companies like Tesla and General Motors investing heavily in new manufacturing processes to accommodate lightweight stamped components.

- Regulatory changes, particularly in emissions standards, are pushing manufacturers to innovate and adopt advanced stamping technologies that enhance fuel efficiency and reduce vehicle weight, with organizations like the Environmental Protection Agency (EPA) playing a crucial role.

Middle East And Africa

- In the Middle East and Africa, the automotive stamped component market is influenced by the growing automotive manufacturing base in countries like South Africa, where local companies are increasingly collaborating with global automotive giants to enhance production capabilities.

- Regulatory frameworks aimed at boosting local manufacturing and reducing import dependency are encouraging investments in stamping technologies, which are expected to improve the competitiveness of the regional automotive industry.

Did You Know?

“Did you know that stamped components can account for up to 30% of the total weight of a vehicle, making them crucial for improving fuel efficiency and reducing emissions?” — Automotive Industry Association Reports

Segmental Market Size

The Automotive Stamped Component Market plays a crucial role in the automotive supply chain, primarily serving as a foundational element in vehicle manufacturing. This segment is currently experiencing growth, driven by increasing vehicle production and the demand for lightweight materials that enhance fuel efficiency. Key factors propelling this demand include the push for electric vehicles (EVs) and stringent regulatory policies aimed at reducing emissions, which necessitate innovative manufacturing solutions. Currently, the market is in a mature adoption stage, with companies like Ford and General Motors leading the way in integrating stamped components into their production lines. Notable applications include body panels, chassis components, and structural parts, which are essential for vehicle safety and performance. Trends such as sustainability initiatives and advancements in automation are catalyzing growth, as manufacturers seek to optimize production processes and reduce waste. Technologies like advanced stamping techniques and materials science innovations are shaping the evolution of this segment, ensuring that automotive stamped components remain integral to modern vehicle design.

Future Outlook

The Automotive Stamped Component Market is poised for steady growth from 2023 to 2032, with a projected market value increase from $54.91 billion to $67.5 billion, reflecting a compound annual growth rate (CAGR) of 2.32%. This growth trajectory is underpinned by the rising demand for lightweight and fuel-efficient vehicles, as manufacturers increasingly adopt stamped components to enhance vehicle performance while reducing overall weight. As electric vehicles (EVs) gain traction, the need for innovative stamped components that support advanced designs and materials will further drive market expansion. By 2032, it is anticipated that stamped components will account for approximately 30% of the total automotive component market, highlighting their critical role in modern vehicle manufacturing. Key technological advancements, such as the integration of automation and smart manufacturing processes, are expected to revolutionize the production of stamped components. The adoption of Industry 4.0 technologies will enable manufacturers to optimize production efficiency and reduce costs, thereby enhancing competitiveness in the market. Additionally, stringent regulations aimed at reducing carbon emissions are likely to propel the demand for lightweight materials, further solidifying the position of stamped components in the automotive sector. As the industry evolves, emerging trends such as the use of advanced high-strength steels and aluminum alloys will shape the future landscape of the automotive stamped component market, ensuring its relevance in an increasingly eco-conscious world.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Growth Rate | (2022-2030 Base Year 2021 Forecast Period 2022-2030 Historical Data 2019 & 2020 Forecast Units Value (USD Billion) Report Coverage Revenue Forecast, Competitive Landscape, Growth Factors, and Trends Segments Covered Forming Temperature, Vehicle Type, and Technology Geographies Covered North America, Europe, Asia-Pacific, and the Rest of the World (RoW) Key Vendors Gestamp, Batesville Tool & Die, Trans-Matic, Lindy Manufacturing, Magna, All-New Stamping Key Market Opportunities Modernization of the stamping process Key Market Drivers High consumption of alloys and metals and Rising production and sale of vehicles |

Automotive Stamped Component Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.