Global Chemical Mechanical Planarization Market Overview:

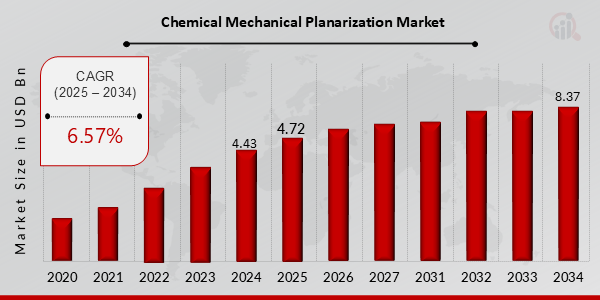

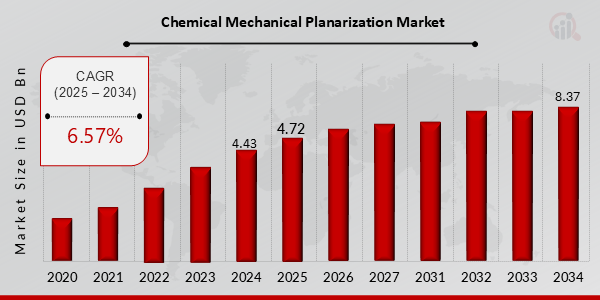

Chemical Mechanical Planarization Market Size was estimated at 4.43 (USD Billion) in 2024. The Chemical Mechanical Planarization Market Industry is expected to grow from 4.72 (USD Billion) in 2025 to 8.37 (USD Billion) till 2034, exhibiting a compound annual growth rate (CAGR) of 6.57% during the forecast period (2025 - 2034)

Key Chemical Mechanical Planarization Market Trends Highlighted

Chemical mechanical planarization (CMP) market is driven by rising demand for advanced semiconductor devices in consumer electronics, automotive, and industrial sectors. CMP is critical in semiconductor manufacturing to achieve flat and smooth surfaces on wafers, enabling miniaturization and performance enhancement.

Key trends include the shift towards CMP consumables and equipment for advanced packaging applications, adoption of innovative technologies like slurryless CMP, and integration of artificial intelligence (AI) and machine learning (ML) for process control. Opportunities lie in the expansion of CMP into emerging markets, such as China and India, and the increasing use of CMP in non-semiconductor applications, such as display manufacturing.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Chemical Mechanical Planarization Market Drivers

Increasing Demand for Advanced Semiconductor Devices

The growing adoption of advanced semiconductor devices, such as those used in smartphones, tablets, and high-performance computing systems, is driving the demand for chemical mechanical planarization (CMP) technology. CMP is a critical process in the manufacturing of semiconductor devices, as it enables the creation of smooth and flat surfaces on the wafers, which is essential for optimal device performance.

The increasing complexity and miniaturization of semiconductor devices require precise and reliable CMP processes, which is expected to drive the growth of the Chemical Mechanical Planarization Market over the forecast period.

Growing Adoption of 3D NAND Flash Memory

The rising popularity of 3D NAND flash memory is another major factor contributing to the growth of the Chemical Mechanical Planarization Market. 3D NAND flash memory offers higher storage capacity and faster data transfer speeds compared to traditional 2D NAND flash memory. The manufacturing process of 3D NAND flash memory involves multiple CMP steps, which is expected to drive the demand for CMP equipment and consumables.

Government Initiatives and Investments

Governments worldwide are increasingly recognizing the strategic importance of the semiconductor industry and are making significant investments in research and development, as well as in the development of domestic semiconductor manufacturing capabilities. These initiatives are expected to boost the demand for CMP technology, as it is a critical process in the manufacturing of advanced semiconductor devices.

Chemical Mechanical Planarization Market Segment Insights:

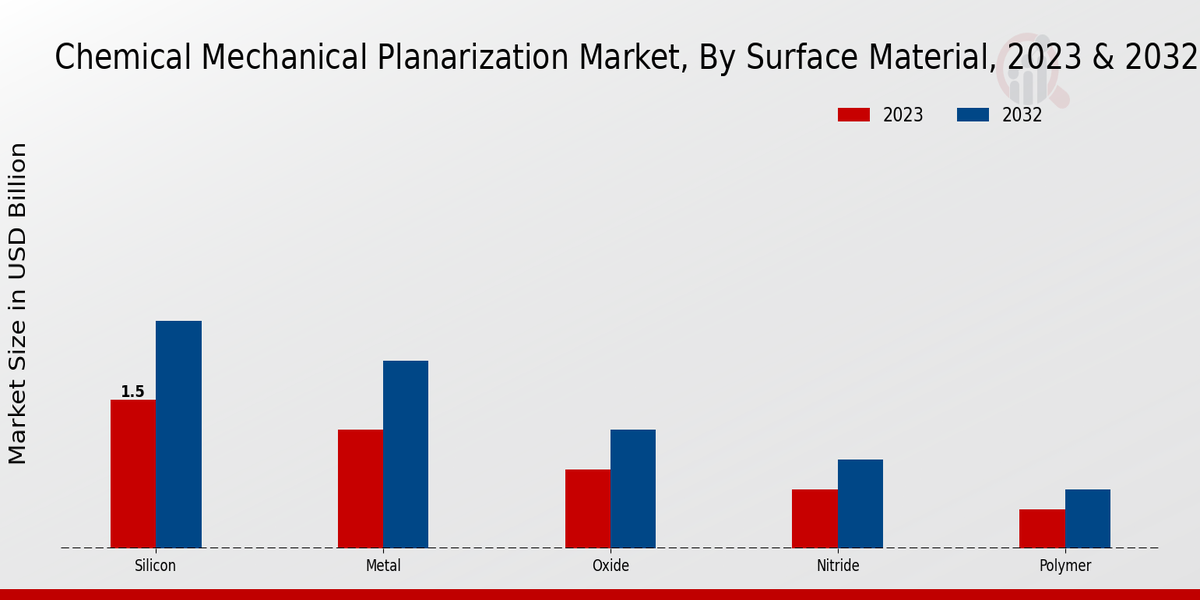

Chemical Mechanical Planarization Market Surface Material Insights

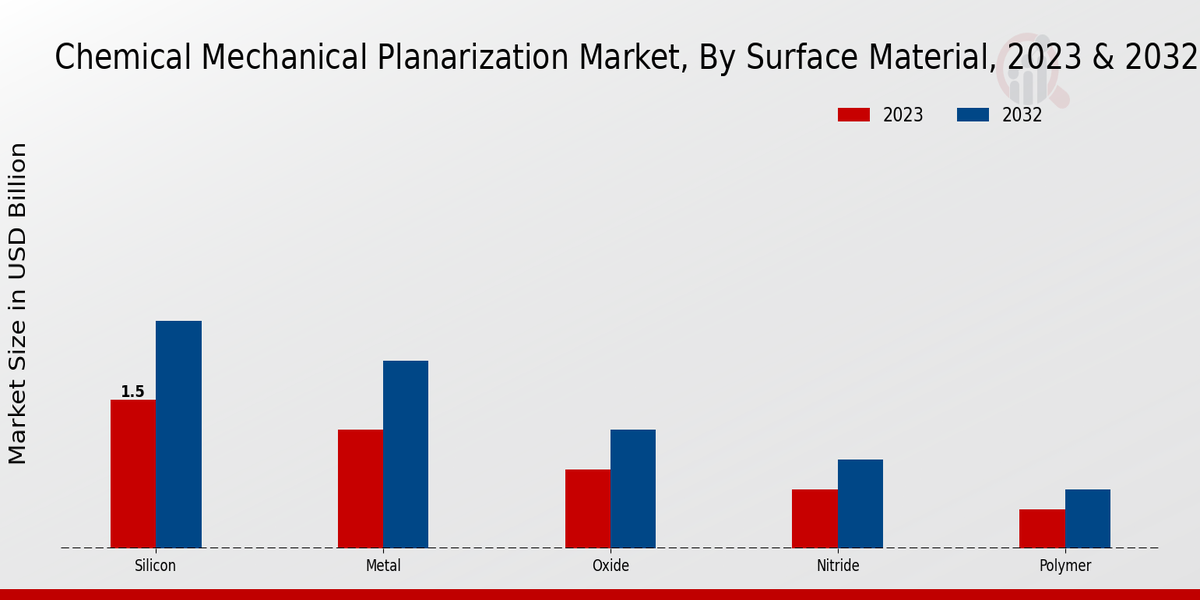

The Chemical Mechanical Planarization Market is segmented by surface material into silicon, metal, oxide, nitride, and polymer. The silicon segment is expected to account for the largest market share in 2023, owing to its widespread use in the production of integrated circuits (ICs).

The metal segment is also expected to witness significant growth, driven by the increasing demand for metal interconnects in advanced ICs. The oxide segment is expected to grow at a steady pace, due to its use in the production of gate oxides and other critical layers in ICs.

The nitride segment is expected to witness moderate growth, owing to its use in the production of passivation layers and other protective coatings in ICs. The polymer segment is expected to grow at a relatively slower pace, due to its limited use in the production of ICs.

In 2023, the market for silicon CMP was valued at USD 1.5 billion and is projected to grow to USD 2.3 billion by 2032, exhibiting a CAGR of 6.0% during the forecast period. The market for metal CMP is expected to be valued at USD 1.2 billion in 2023 and is projected to grow to USD 1.9 billion by 2032, exhibiting a CAGR of 6.2% during the forecast period.

The Chemical Mechanical Planarization Market for oxide is expected to be valued at USD 0.8 billion in 2023 and is projected to grow to USD 1.2 billion by 2032, exhibiting a CAGR of 5.8% during the forecast period.

The Chemical Mechanical Planarization Market for nitride is expected to be valued at USD 0.6 billion in 2023 and is projected to grow to USD 0.9 billion by 2032, exhibiting a CAGR of 5.5% during the forecast period.

The Chemical Mechanical Planarization Market for polymer is expected to be valued at USD 0.4 billion in 2023 and is projected to grow to USD 0.6 billion by 2032, exhibiting a CAGR of 5.2% during the forecast period.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Chemical Mechanical Planarization Market Application Insights

The global chemical mechanical planarization (CMP) market is segmented by application into semiconductor fabrication, MEMS manufacturing, hard disk drive production, optical component manufacturing, and printed circuit board manufacturing.

Semiconductor fabrication dominated the market in 2023, accounting for over 60% of the global revenue. This dominance is attributed to the increasing demand for advanced semiconductor devices, such as those used in smartphones, laptops, and data centers.

MEMS Manufacturing is another significant application segment, expected to witness substantial growth over the forecast period. MEMS devices are used in various industries, including automotive, healthcare, and consumer electronics. The growing adoption of MEMS devices in these industries is driving the demand for CMP solutions.

Hard disk drive production is a mature application segment, but it is still expected to contribute to overall market growth. The demand for CMP solutions in this segment is driven by the increasing demand for high-capacity hard disk drives (HDDs) used in data centers and enterprise storage systems.

Optical component manufacturing and printed circuit board manufacturing are emerging application segments for CMP. The growing demand for high-performance optical components and printed circuit boards (PCBs) is driving the adoption of CMP solutions in these segments.

Chemical Mechanical Planarization Market Slurry Type Insights

The Chemical Mechanical Planarization Market segmentation provides valuable data based on slurry type, including colloidal silica, ceria, alumina, tantalum, and tungsten. Colloidal silica, with its high purity and consistent particle size, dominates the market.

Ceria slurry exhibits excellent polishing performance and is expected to witness significant growth. Alumina slurry offers cost-effective solutions and is suitable for various applications. Tantalum and Tungsten slurries cater to specific requirements, such as high removal rates and low dishing.

In 2023, the market revenue for colloidal silica was valued at USD 1.29 billion, while Ceria slurry generated a revenue of USD 0.98 billion. The market for alumina slurry is projected to reach USD 0.76 billion by 2032, growing at a steady rate. Tantalum and tungsten slurries are estimated to contribute to the market growth with increasing demand for advanced semiconductor devices.

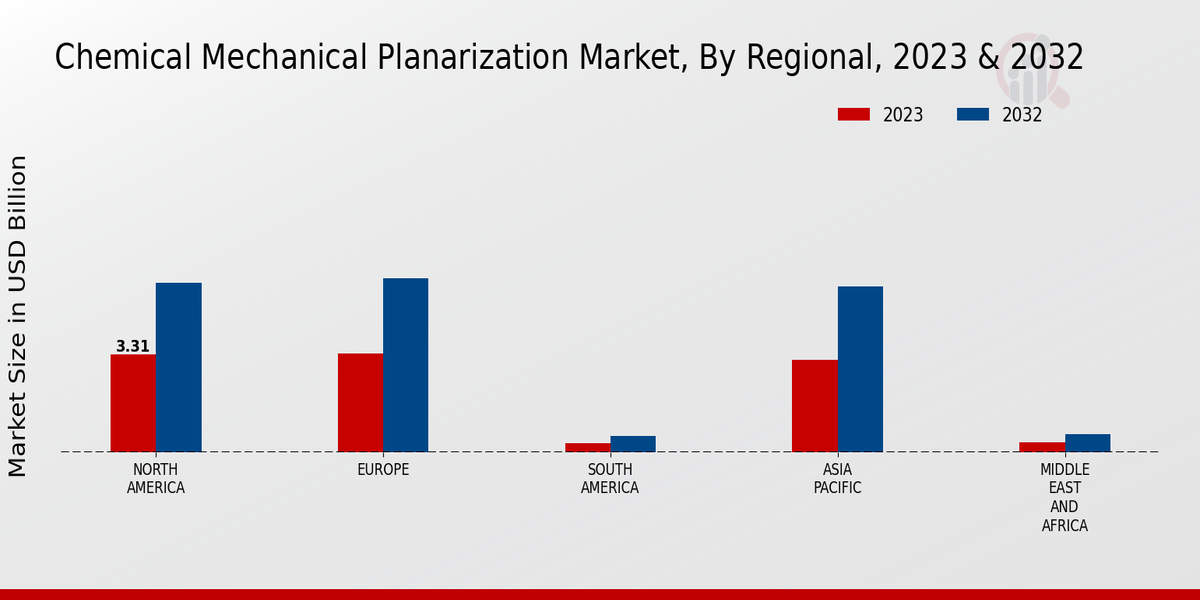

Chemical Mechanical Planarization Market Regional Insights

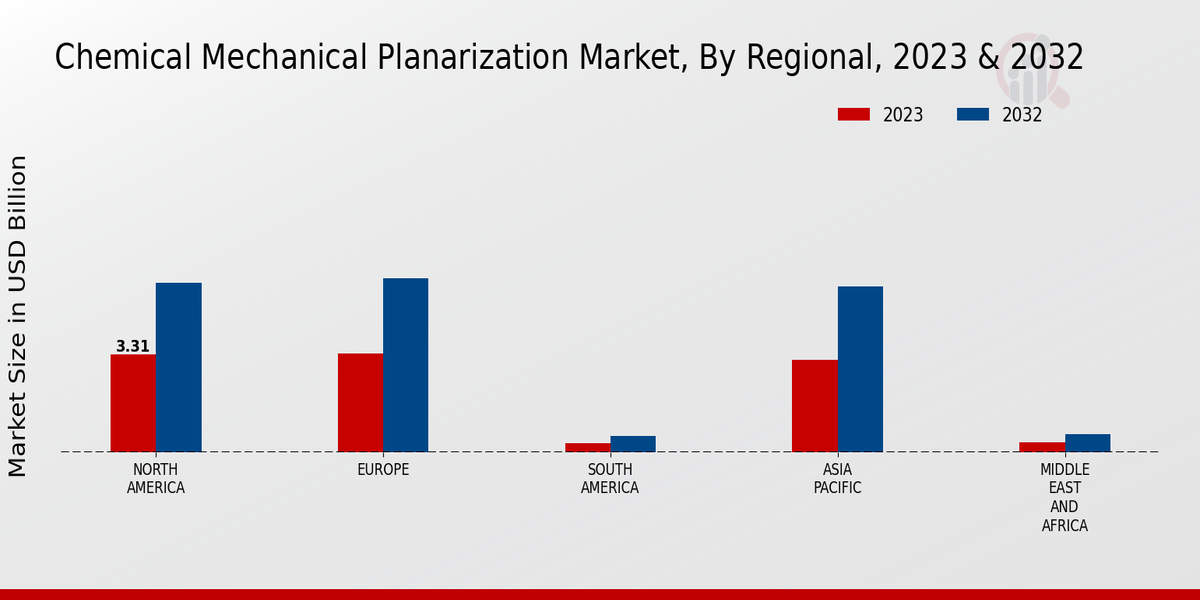

The Chemical Mechanical Planarization Market is segmented into North America, Europe, APAC, South America, and MEA. North America is expected to continue to dominate the market, accounting for a significant share of the global revenue in 2024 and beyond. The growth in this region can be attributed to the increasing adoption of advanced semiconductor technologies and the presence of major semiconductor manufacturers.

Europe is expected to be the second-largest market, followed by APAC. The APAC region is expected to witness significant growth in the coming years, driven by the increasing demand for electronic devices in developing countries such as China and India. South America and MEA are expected to have a relatively smaller share of the global market.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Chemical Mechanical Planarization Market Key Players and Competitive Insights:

Major players are constantly innovating and developing new products to meet the evolving needs of the market. Leading chemical mechanical planarization market players are focusing on expanding their global presence and increasing their market share.

The chemical mechanical planarization market is expected to witness significant growth in the coming years, driven by the increasing demand for semiconductors and the growing adoption of advanced packaging technologies. The competitive landscape of the Chemical Mechanical Planarization Market is characterized by the presence of both established and emerging players.

Applied Materials, Inc. is a leading provider of chemical mechanical planarization equipment and materials. The company offers a wide range of CMP products, including slurries, pads, and conditioners. Applied Materials has a strong global presence and a large customer base. The company is focused on developing innovative CMP solutions that meet the needs of its customers.

Lam Research Corporation is another major player. The company offers a comprehensive portfolio of CMP products, including slurries, pads, and conditioners. Lam Research has a strong focus on research and development, and it is constantly innovating to improve its CMP products. The company has a global presence and a large customer base.

Key Companies in the Chemical Mechanical Planarization Market Include:

Chemical Mechanical Planarization Market Developments

-

Q2 2024: Entegris Opens New Manufacturing Facility in Taiwan to Expand CMP Slurry Production Entegris announced the opening of a new manufacturing facility in Kaohsiung, Taiwan, dedicated to increasing production capacity for chemical mechanical planarization (CMP) slurries to support the region’s growing semiconductor industry.

-

Q1 2024: DuPont Launches Next-Generation CMP Pad for Advanced Semiconductor Nodes DuPont introduced a new CMP pad designed for use in advanced semiconductor manufacturing, targeting improved defectivity and higher yields for leading-edge chipmakers.

-

Q2 2024: CMC Materials Announces Strategic Partnership with Samsung Electronics for CMP Materials Supply CMC Materials entered into a multi-year supply agreement with Samsung Electronics to provide advanced CMP slurries and pads for next-generation memory and logic device fabrication.

-

Q3 2024: Applied Materials Unveils New CMP Equipment Platform for 3D NAND and Logic Devices Applied Materials launched a new chemical mechanical planarization equipment platform engineered to address the unique challenges of 3D NAND and advanced logic device manufacturing.

-

Q2 2024: Ebara Opens CMP R&D Center in the United States Ebara Corporation inaugurated a new research and development center in Oregon, USA, focused on developing next-generation CMP tools and process solutions for the North American semiconductor market.

-

Q1 2024: Entegris Appoints New Chief Technology Officer to Lead CMP Innovation Entegris named Dr. Lisa Chen as Chief Technology Officer, tasking her with driving innovation in CMP materials and process solutions for the global semiconductor industry.

-

Q2 2024: DuPont Acquires Minority Stake in CMP Startup NanoPlanar DuPont acquired a 20% stake in NanoPlanar, a startup specializing in novel CMP slurry formulations, to accelerate the development of advanced planarization materials for sub-5nm semiconductor nodes.

-

Q3 2024: Cabot Microelectronics Expands CMP Pad Manufacturing in Singapore Cabot Microelectronics announced the expansion of its CMP pad manufacturing facility in Singapore to meet rising demand from Asian semiconductor foundries.

-

Q2 2024: Applied Materials Wins Major CMP Equipment Contract from TSMC Applied Materials secured a significant contract to supply CMP equipment to TSMC for its new advanced logic and memory fabrication lines.

-

Q1 2024: Ebara Corporation Signs CMP Equipment Supply Agreement with Intel Ebara Corporation entered into a multi-year agreement to supply CMP equipment and process support to Intel’s U.S. and European fabs.

-

Q2 2024: DuPont Receives Regulatory Approval for New CMP Slurry Plant in South Korea DuPont received final regulatory clearance to begin operations at its new CMP slurry manufacturing plant in South Korea, aimed at supporting local and regional semiconductor customers.

-

Q3 2024: Entegris Raises $300 Million in Green Bond Offering to Fund Sustainable CMP Manufacturing Entegris completed a $300 million green bond issuance, with proceeds earmarked for sustainable manufacturing initiatives, including eco-friendly CMP slurry production.

Chemical Mechanical Planarization Market Segmentation Insights

Chemical Mechanical Planarization Market Surface Material Outlook

Chemical Mechanical Planarization Market Application Outlook

- Semiconductor Fabrication

- Hard Disk Drive Production

- Optical Component Manufacturing

- Printed Circuit Board Manufacturing

Chemical Mechanical Planarization Market Slurry Type Outlook

Chemical Mechanical Planarization Market Regional Outlook

|

Report Attribute/Metric

|

Details

|

|

Market Size 2024

|

USD 4.43 Billion

|

|

Market Size 2025

|

USD 4.72 Billion

|

|

Market Size 2034

|

USD 8.37 Billion

|

|

Compound Annual Growth Rate (CAGR)

|

6.57% (2025-2034)

|

|

Base Year

|

2024

|

|

Market Forecast Period

|

2025-2034

|

|

Historical Data

|

2020-2023

|

| Market Forecast Units |

USD Billion |

| Key Companies Profiled |

Mattson Technology, Inc., Hitachi HighTechnologies Corporation, Ebara Corporation, Daikin Industries, Ltd., KLA Corporation, SUMCO Corporation, Toyota Motor Corporation, ShinEtsu Chemical Co., Ltd., ASML Holding N.V., Tokyo Electron Ltd, Lam Research Corporation, Fujimi Incorporated, Applied Materials, Inc. |

| Segments Covered |

Surface Material, Application, Slurry Type, Region |

| Key Market Opportunities |

Advanced semiconductor packaging. Growing demand for miniaturization Surge in AI applications. Increased use of CMP in solar cell manufacturing CMP integration in advanced display technologies . |

| Key Market Dynamics |

Rising semiconductor demand. Increased adoption of advanced packaging. Growing demand for high performance electronics. Technological advancements. Stringent environmental regulations. |

| Countries Covered |

North America, Europe, APAC, South America, MEA |

Frequently Asked Questions (FAQ):

The Chemical Mechanical Planarization market totaled USD 4.43 billion in 2024.

The Chemical Mechanical Planarization market is projected to grow at a CAGR of 6.57% from 2025 to 2034

Asia Pacific held the largest market share in the Chemical Mechanical Planarization market in 2023.

Key applications of Chemical Mechanical Planarization include semiconductor manufacturing, flat panel display production, and data storage.

Key competitors in the Chemical Mechanical Planarization market include Applied Materials, KLA Corporation, and Lam Research.

Key trends driving the growth of the Chemical Mechanical Planarization market include the increasing demand for advanced semiconductor devices and the growing adoption of flat panel displays.

Key challenges facing the Chemical Mechanical Planarization market include the high cost of equipment and the need for skilled labor.

Key opportunities for the Chemical Mechanical Planarization market include the growing demand for advanced semiconductor devices and the increasing adoption of flat panel displays.

Key strategies adopted by the key players in the Chemical Mechanical Planarization market include product innovation, strategic partnerships, and geographical expansion.

The Chemical Mechanical Planarization market is projected to reach USD 6.91 billion by 2032.