- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

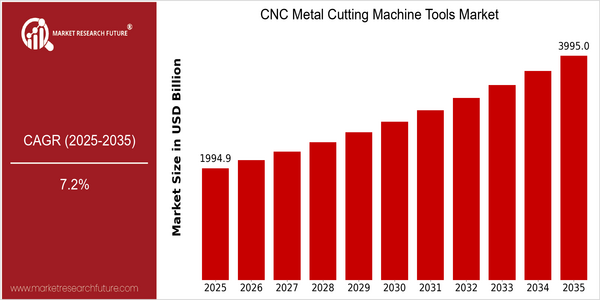

Market Size Snapshot

| Year | Value |

|---|---|

| 2025 | USD 1994.87 Billion |

| 2035 | USD 3995.0 Billion |

| CAGR (2025-2035) | 7.2 % |

Note – Market size depicts the revenue generated over the financial year

The CNC machine tool market is expected to reach $ 2,995,083,941,000 by 2035. This will be a yearly growth of 7.2%. The demand for automation and precision in manufacturing is the main reason for this growth. Industries want to increase their productivity and reduce their costs. The development of the machine tool, such as the integration of IoT and artificial intelligence, is revolutionizing the industry. It enables more efficient and smarter production. The main companies in the CNC machine tool market, such as DMG Mori, Haas automation and Mazak, are constantly investing in research and development. Strategic alliances are also taking place. These companies want to use complementary technology and gain access to new markets. Product launches with advanced automation features and improved graphical user interfaces are a clear sign of this trend. As these developments continue, the demand for the CNC machine tool will continue to grow.

Regional Market Size

Regional Deep Dive

The CNC Metal Cutting Machine Tools Market is expected to grow at a significant CAGR during the forecast period. The demand for precision engineering is increasing, and the development of the manufacturing industry is undergoing changes. The North American market is characterized by a strong presence of established manufacturers and a focus on automation and smart manufacturing solutions. The European market is stable and focuses on sustainable and sustainable solutions. The Asia-Pacific market is growing rapidly due to the rapid industrialization and the development of the economy. The Middle East and Africa are slowly growing, influenced by the diversification of economies. Latin America is beginning to show potential due to the increase in the manufacturing industry.

Europe

- Germany remains a key player in the European CNC metal cutting machine tools market, with companies such as Trumpf and Siemens driving innovation in energy-efficient and high-precision machines.

- The European Union's Green Deal is pushing manufacturers to adopt more sustainable practices, leading to increased demand for CNC machines that minimize waste and energy consumption.

Asia Pacific

- China's rapid industrialization and government initiatives like 'Made in China 2025' are significantly boosting the demand for CNC metal cutting tools, with local companies like Hitec Products gaining prominence.

- Japan is focusing on integrating AI and IoT into CNC machines, with firms like Fanuc and Yaskawa Electric leading the charge in smart manufacturing technologies.

Latin America

- Brazil is emerging as a significant market for CNC metal cutting tools, driven by a resurgence in its automotive and aerospace industries, with companies like Embraco investing in modern manufacturing technologies.

- The region is witnessing a shift towards automation, with local governments encouraging investments in CNC technologies to enhance productivity and competitiveness in manufacturing.

North America

- The U.S. is leading the North American market, with companies like Haas Automation and DMG Mori investing heavily in R&D to enhance CNC technology, focusing on automation and Industry 4.0 solutions.

- Recent regulatory changes aimed at promoting advanced manufacturing practices have encouraged investments in CNC machine tools, particularly in sectors like aerospace and automotive, which are critical to the region's economy.

Middle East And Africa

- The UAE is investing in advanced manufacturing technologies as part of its Vision 2021 initiative, which is expected to increase the demand for CNC machine tools in the region.

- South Africa is seeing growth in the CNC market due to government programs aimed at revitalizing the manufacturing sector, with local firms beginning to adopt more advanced machining technologies.

Did You Know?

“Did you know that CNC machines can operate 24/7 without breaks, significantly increasing production efficiency compared to traditional machining methods?” — CNC Cookbook

Segmental Market Size

The machine-building industry plays a crucial role and is growing at a constant rate. Its importance is attributable to the ever increasing automation and precision requirements of the metal-working industries. The demand for high-quality and cost-effective production processes is augmented by developments in CNC technology that enhance their capabilities. The government’s policy of encouraging safety and productivity in manufacturing is also a factor in the growth of the industry. The global market for CNC metal-working machinery is now well established. DMG Mori and Haas Automation lead the field in the deployment of this technology, particularly in North America and Europe. These machines are used in the manufacture of components for the car, aero engines and other industries where the cutting of metal with precision is essential. The development of the Internet of Things and smart manufacturing are also contributing to the growth of the industry. Energy-saving machines are also playing an increasingly important role. In this regard, the evolution of advanced robotics and the integration of data analytics based on artificial intelligence are enabling manufacturers to optimize their operations and reduce waste.

Future Outlook

The CNC metal-cutting machine tool market is expected to grow from about $1.8 billion to $3.9 billion from 2025 to 2035, with a CAGR of 7.2%. This growth is driven by the increasing demand for precision machinery in various industries, such as the automobile, aerospace and manufacturing industries. The penetration of CNC machining centers will also increase, and the rate of penetration in the manufacturing industry will be higher than 60% in 2035. Artificial intelligence and the Internet of Things will be combined with CNC machining processes, and they will be expected to improve efficiency and productivity. This innovation will allow real-time monitoring and preventive maintenance to reduce downtime and operating costs. Government support for advanced manufacturing and energy conservation will also promote market growth. The trend of additive manufacturing and hybrid machining will also change the competition landscape in the next ten years, and there will be new opportunities for industry players to differentiate their products.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 68.9 Billion |

| Market Size Value In 2023 | USD 73.2 Billion |

| Growth Rate | 6.20% (2023-2032) |

CNC Metal Cutting Machine Tools Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.