CNC Metal Cutting Machine Tools Market Summary

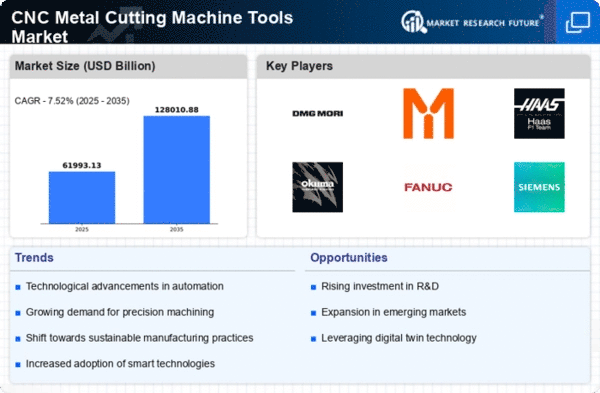

As per MRFR analysis, the CNC Metal Cutting Machine Tools Market was estimated at 57657.3 USD Billion in 2024. The CNC Metal Cutting Machine Tools industry is projected to grow from 61993.27 USD Billion in 2025 to 128010.88 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 7.52% during the forecast period 2025 - 2035.

Key Market Trends & Highlights

The CNC Metal Cutting Machine Tools Market is experiencing a dynamic shift towards automation and sustainability.

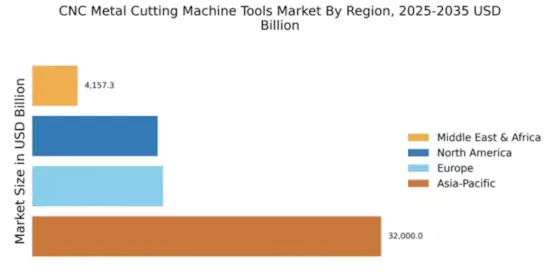

- North America remains the largest market for CNC metal cutting machine tools, driven by advanced manufacturing capabilities.

- The Asia-Pacific region is recognized as the fastest-growing market, fueled by rapid industrialization and technological adoption.

- The metal fabrication segment continues to dominate the market, while the aerospace segment is emerging as the fastest-growing area.

- Technological advancements and the rising demand for customization are key drivers propelling market growth.

Market Size & Forecast

| 2024 Market Size | 57657.3 (USD Billion) |

| 2035 Market Size | 128010.88 (USD Billion) |

| CAGR (2025 - 2035) | 7.52% |

Major Players

DMG Mori (DE), Mazak (JP), Haas Automation (US), Okuma (JP), Fanuc (JP), Siemens (DE), Emag (DE), Hurco (US), Toshiba Machine (JP)