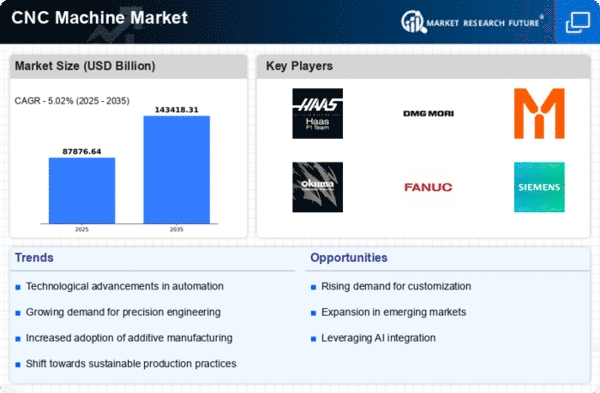

The CNC Machine Market is currently experiencing a transformative phase characterized by rapid technological advancements and evolving consumer demands. Automation and precision engineering are at the forefront, driving manufacturers to innovate and enhance their product offerings. The global demand for high-precision CNC machines continues to rise as manufacturers prioritize automated production cycles.

The integration of artificial intelligence and machine learning into CNC systems appears to be reshaping operational efficiencies, enabling businesses to achieve higher levels of productivity and accuracy.

Furthermore, the growing emphasis on sustainability and eco-friendly practices is influencing the design and manufacturing processes within the sector, as companies strive to reduce their environmental footprint while maintaining competitive advantages.

The CNC Machine Market is witnessing a shift towards customization and flexibility in production. With a rising demand for small CNC machines which are suitable for Space-constrained workshops, This market is also focusing providing high-precision output without a large physical footprint.

As industries increasingly seek tailored solutions to meet specific requirements, CNC machinery are being adapted to accommodate diverse applications across various sectors. This trend suggests a potential for growth in niche markets, where specialized machinery can cater to unique manufacturing needs.

Overall, the CNC Machine Market is poised for continued evolution, driven by technological innovation and changing market dynamics, which may lead to new opportunities and challenges in the coming years.

Integration of Smart Technologies

The incorporation of smart technologies into CNC machines is revolutionizing the manufacturing landscape. Automation and artificial intelligence are enhancing operational efficiency, enabling predictive maintenance, and reducing costs. This trend indicates a growing demand for intelligent solutions that optimize production processes.

Focus on Sustainability

There is a growing emphasis on sustainable practices within the CNC Machine Market. Companies are increasingly adopting eco-friendly materials and processes, aiming to minimize their environmental impact while meeting regulatory standards and consumer expectations. The transition toward sustainable manufacturing has led to the development of energy-efficient CNC machinery models.

Customization and Precision

The demand for customized solutions is rising, prompting manufacturers to develop CNC machines that can adapt to various applications. Maintaining high-tier CNC equipment requires a skilled workforce capable of handling sophisticated software interfaces.This trend indicates a shift towards more versatile machinery capable of handling diverse production needs.

Long-Term Stability Factor

When evaluating CNC machine cost, stakeholders often consider the long-term savings generated by reduced scrap rates. In the CNC machine market, the structural integrity and mechanical stability of older units are often the primary reasons they are considered for refurbishment rather than replacement. This is a strong reason for that used CNC machines are opted for.