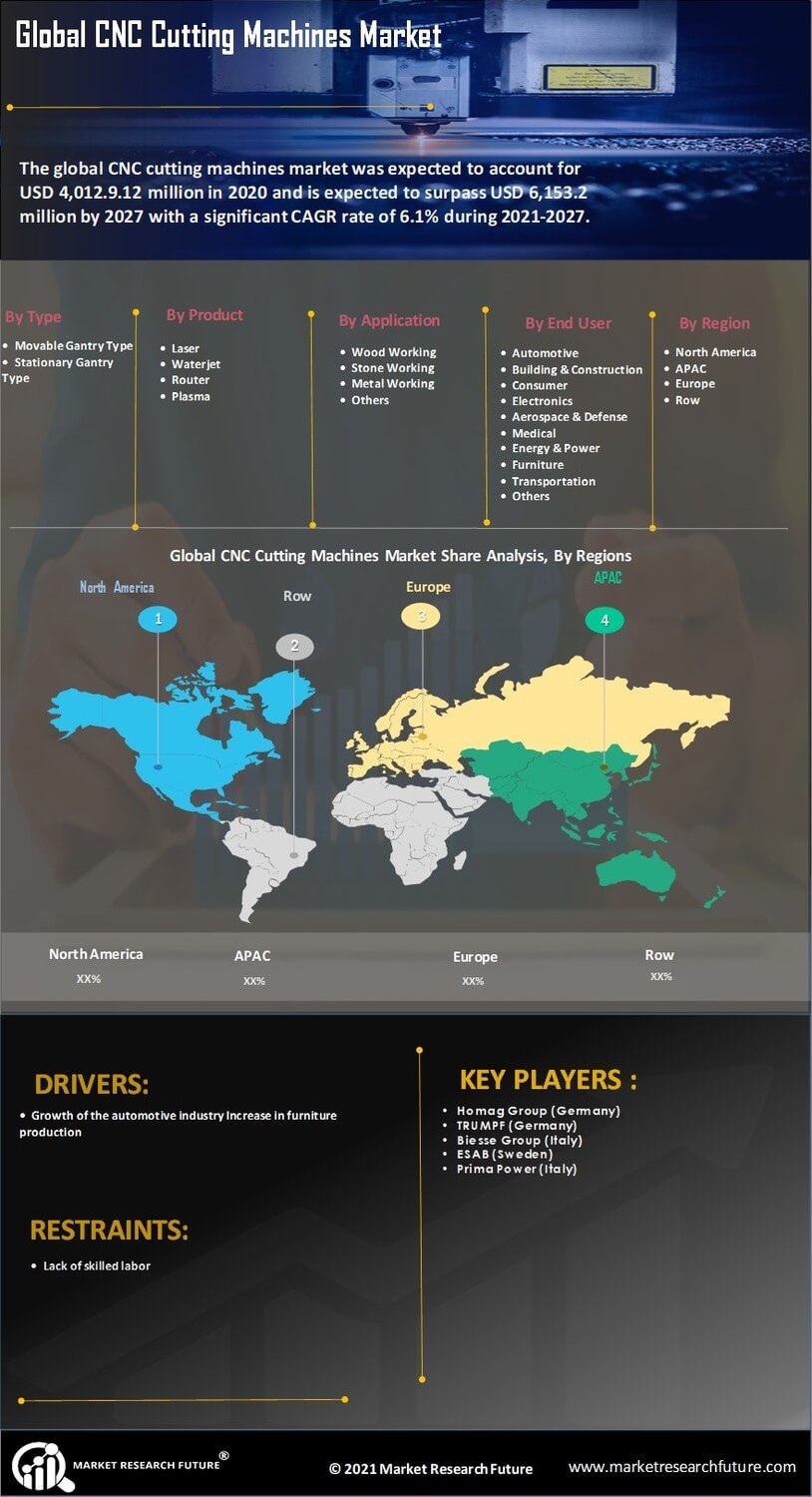

CNC Cutting Machines Market Summary

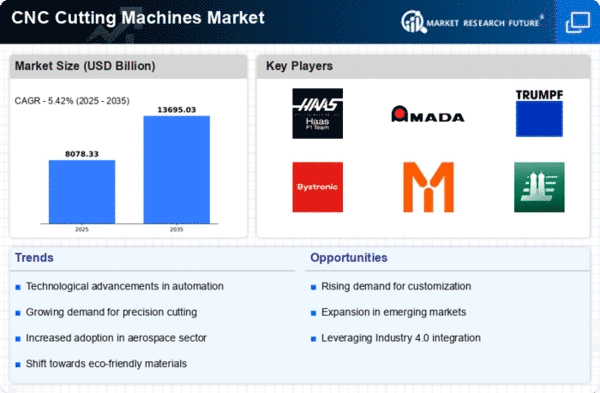

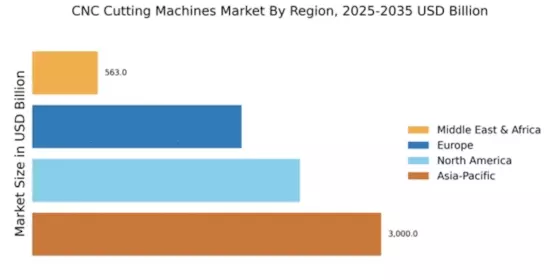

As per MRFR analysis, the CNC Cutting Machines Market Size was estimated at 7663.0 USD Billion in 2024. The CNC Cutting Machines industry is projected to grow from 8078.35 USD Billion in 2025 to 13695.03 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 5.42% during the forecast period 2025 - 2035.

Key Market Trends & Highlights

The CNC Cutting Machines Market is poised for robust growth driven by technological advancements and increasing demand for precision.

- Technological advancements are reshaping the CNC cutting machines landscape, enhancing efficiency and capabilities.

- The demand for customization in manufacturing processes is rising, particularly in the automotive sector in North America.

- Sustainability is becoming a focal point, influencing the adoption of eco-friendly practices in CNC cutting operations.

- Increased automation in manufacturing and the expansion of the automotive sector are key drivers propelling market growth.

Market Size & Forecast

| 2024 Market Size | 7663.0 (USD Billion) |

| 2035 Market Size | 13695.03 (USD Billion) |

| CAGR (2025 - 2035) | 5.42% |